If you’ve ever asked for a circuit board assembly quote, you’ve probably noticed how prices vary dramatically from one supplier to another. Some factories offer surprisingly low prices, while others seem much higher — even with the same BOM.

So what’s the difference?

The truth is, PCB assembly pricing involves far more than just the component cost. Every step — from part sourcing and quality checks to testing, packaging, and warranty — affects both cost and long-term reliability.

This guide will help you understand what really matters in PCB assembly services, how to compare suppliers fairly, and how to make sure you get the best value for your project.

Understanding What You’re Actually Paying For

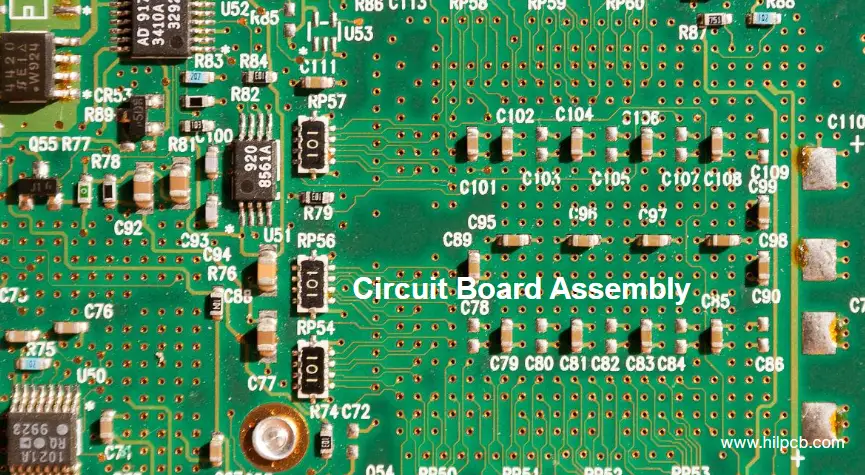

When you receive a PCB assembly quote, you’re not just paying for someone to solder components onto a board. Here’s what a complete quote from a professional circuit board manufacturer typically includes:

- BOM Components — The base price of parts from verified distributors.

- Sourcing and Verification — Checking authenticity, batch codes, and compliance to prevent counterfeit components.

- Assembly Labor and Process Control — SMT placement, reflow, inspection, and handling.

- Testing and Quality Assurance — Electrical, optical, and X-ray verification.

- Packaging and Logistics — ESD-safe protection, labeling, and moisture control.

- After-Sales Support and Warranty — Coverage for rework, replacement, or troubleshooting.

Low-cost suppliers often skip or reduce these steps — saving a few dollars now, but risking far greater losses later in rework, returns, or production delays.

If you want your boards built for reliability, make sure your assembler follows full process control like those in circuit board fabrication and circuit board production.

The Real Cost Drivers in PCB Assembly

1. Component Sourcing and BOM Verification

For many buyers, BOM pricing seems like the main focus — but it’s only the starting point. What matters more is where and how the parts are sourced.

A professional assembler like HILPCB sources from authorized distributors such as Digi-Key, Mouser, or Arrow. Every component batch is inspected for authenticity, shelf life, and packaging integrity. This prevents fake or mixed-lot components from entering your production line.

When shortages occur, our team helps identify equivalent alternatives or drop-in replacements to keep your build moving — a service that inexperienced assemblers often can’t provide. Learn how our material evaluation ties into upstream circuit board manufacturing processes.

2. Process Control and Component Loss

Even with the same BOM, every factory’s process control is different. For example, during SMT assembly, every feeder setup, reflow calibration, or pick-and-place test requires a small number of extra parts.

Typical component loss averages 1–3%, depending on packaging and complexity. Factories that ignore this reality often quote low prices but later increase cost or delay production due to shortages.

At HILPCB, we include realistic loss and quality control parameters in every quote, ensuring production efficiency without unexpected cost increases. That’s why consistent process monitoring — like we use in our circuit board factory — is critical for long-term stability.

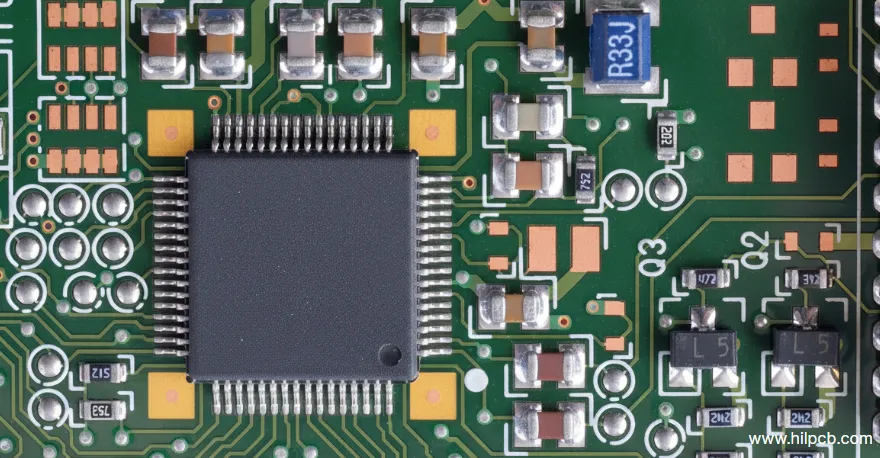

3. Testing and Quality Assurance

No matter how precise your assembly process is, testing is where reliability is proven. A professional circuit board assembly company doesn’t rely on visual checks alone — it performs multiple layers of testing:

- AOI (Automated Optical Inspection) for surface defects

- X-ray analysis for BGA solder joints

- Functional testing for real-world electrical performance

- ICT (In-Circuit Testing) for component-level verification

These steps ensure every board shipped meets the same standard you approved during circuit board prototyping.

4. Packaging, Logistics, and After-Sales Support

Many buyers underestimate the importance of proper packaging and post-delivery support. In reality, these steps protect your investment.

- ESD-safe vacuum packaging prevents static and oxidation.

- Barcode labeling and serialization maintain traceability.

- On-demand logistics support helps manage staggered shipments.

- After-sales warranty and rework service protect you from future downtime.

HILPCB’s in-house logistics and service teams handle everything from production to post-sale technical support, ensuring smooth coordination between circuit board company departments.

How to Compare PCB Assembly Quotes Fairly

When comparing different circuit board assembly suppliers, don’t just look at the total number — look at what’s included.

| Factor | Low-Cost Factory | Reliable Manufacturer |

|---|---|---|

| Component Source | Unknown brokers | Authorized distributors |

| Inspection | Minimal | Full AOI + X-ray |

| Testing | Basic or none | ICT/FCT verification |

| Warranty | Often none | Included rework policy |

| Communication | Slow or unclear | Dedicated engineer support |

Choosing the lowest price can lead to production delays, component mismatches, or field failures. Working with a reliable circuit board supplier may cost slightly more upfront but saves money in long-term stability, warranty coverage, and predictable lead times.

Reducing Cost Without Reducing Quality

If you’re under budget pressure, there are still ways to control cost without cutting corners.

- Optimize your design early — Collaborate with your manufacturer during the circuit board design phase.

- Standardize components — Avoid obsolete or rare parts that drive up sourcing cost.

- Use turnkey PCB assembly — Let your partner handle sourcing, fabrication, and assembly together for efficiency.

- Plan batch sizes — Larger runs reduce setup cost per board.

A single integrated manufacturer like HILPCB — combining design, fabrication, assembly, and testing — eliminates the risks of multi-vendor coordination and hidden markups.

Why Choose HILPCB for Circuit Board Assembly

HILPCB has supported startups and global OEMs alike with complete, transparent PCB solutions — from prototype to mass production.

Why customers choose us:

- Clear, itemized quotes with full BOM visibility

- Authorized and traceable component sourcing

- Integrated circuit board production and assembly lines

- Automated process control and continuous quality testing

- Real-time communication and after-sales technical support

Whether you’re building your first prototype or scaling to high-volume production, our team ensures you get the right balance of price, performance, and reliability.

Frequently Asked Questions

How do I know if my PCB quote is fair?

Compare what’s included — materials, inspection, testing, and warranty — not just the lowest total.

Can I send my own BOM for evaluation?

Yes, we’ll review your BOM, check availability, and suggest cost-saving alternatives before production.

Do you support prototype and mass production orders?

Yes, we handle everything from small runs to full-scale manufacturing.

What’s the advantage of turnkey PCB assembly?

Turnkey assembly combines sourcing, fabrication, and assembly under one factory, saving time and reducing coordination errors.

How long does PCB assembly usually take?

Typical turnaround is 5–10 business days for standard projects, or faster for prototypes.