Modern PCBs are more complex than ever, featuring dense layouts, high-speed signals, and multi-layered architectures operating at gigahertz frequencies. As a result, even minor electrical defects can lead to system failures, product recalls, or costly downtime. That’s why electrical testing is no longer optional—it’s a critical step in ensuring every board meets performance expectations before it reaches the end user.

Why PCB Electrical Testing is Critical

Electrical testing serves as the primary validation checkpoint ensuring circuit functionality and long-term reliability before products reach end users. Without proper electrical verification, manufacturers face significant risks including costly recalls and warranty claims.

Circuit integrity verification ensures all connections function as designed while identifying manufacturing defects including open circuits, short circuits, and component value deviations. Quality assurance through electrical testing reduces field failure rates by 85-95% compared to visual inspection alone, with early defect detection costing significantly less than post-delivery failures.

Regulatory compliance requirements mandate electrical testing for safety-critical applications including automotive, medical devices, and aerospace systems. These industries require documented test results demonstrating product safety before market approval.

For high-frequency PCB applications, electrical testing becomes particularly critical as signal integrity issues invisible to visual inspection can cause system failures in deployed products.

PCB Electrical Testing Methods

Professional electrical testing employs multiple measurement technologies addressing different aspects of circuit performance through systematic verification protocols.

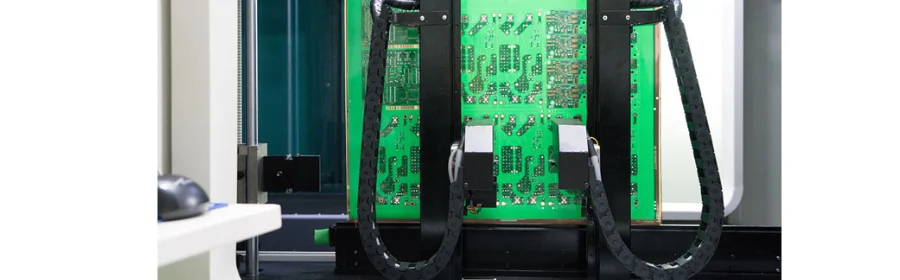

In-Circuit Testing (ICT) utilizes bed-of-nails fixtures providing direct access to individual components. ICT systems measure component values with ±0.1% accuracy while detecting assembly defects including wrong components and solder joint problems. Testing covers resistance, capacitance, and inductance measurements across audio through RF frequencies.

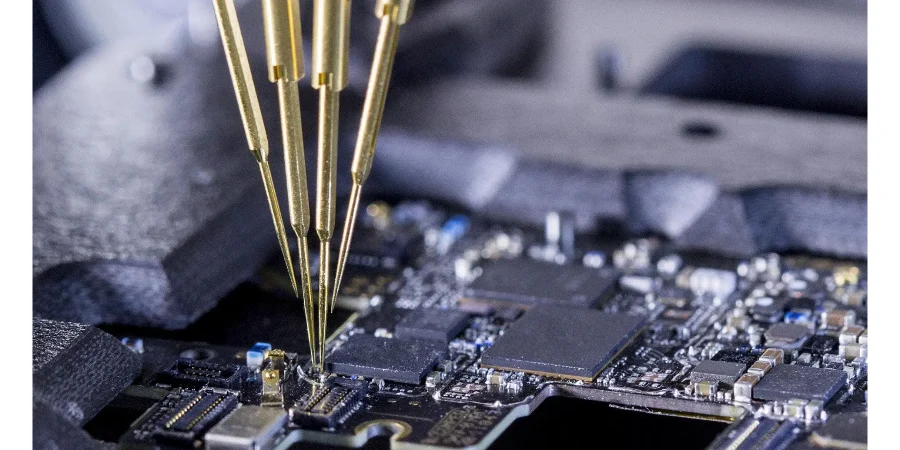

Flying Probe Testing employs precision probes positioned with ±25µm accuracy enabling flexible testing without fixture requirements. This approach proves valuable for prototype verification and low-volume production where fixture costs become prohibitive.

Boundary Scan Testing uses IEEE 1149.1 JTAG protocols enabling digital circuit verification without physical probe access. This method proves essential for high-density assemblies featuring BGA packages where traditional probing becomes impractical.

Functional Testing validates complete system operation under specified conditions including power-on sequences and performance characteristics. Advanced high-speed PCB applications require specialized signal integrity measurements including impedance characterization and eye diagram analysis.

Electrical Testing Standards

Industry standards provide systematic frameworks ensuring consistent testing quality across different manufacturing environments and application requirements.

Automotive Standards: AEC-Q100 qualification requirements mandate comprehensive electrical characterization including temperature coefficient testing and voltage stress analysis addressing harsh operating environments and extended temperature ranges.

Medical Device Compliance: IEC 60601 standards establish rigorous electrical safety requirements including isolation testing, leakage current measurement, and patient protection verification requiring dual-level testing for both functional performance and safety compliance.

Telecommunications Requirements: ITU-T recommendations define electrical testing protocols including bit error rate testing, jitter analysis, and frequency response characterization ensuring interoperability across manufacturers while maintaining signal quality requirements.

Quality management integration utilizes statistical process control enabling real-time monitoring of manufacturing consistency. Professional impedance calculator tools support test program development while circuit simulator capabilities enable pre-test validation of expected results.

How to Implement Electrical Testing

Successful electrical testing implementation requires systematic planning, appropriate equipment selection, and integration with manufacturing processes to maximize effectiveness while controlling costs.

Test Strategy Development: Effective implementation begins with comprehensive test strategy considering product requirements, manufacturing volumes, and quality objectives. Risk analysis identifies critical test points while fault simulation predicts defect detection capabilities enabling optimized test coverage decisions.

Equipment Selection: Testing equipment selection depends on circuit complexity, frequency requirements, and production volumes. Automated test equipment provides high-throughput capability for volume production while manual systems offer flexibility for prototypes and specialized applications.

Manufacturing Integration: SMT assembly processes benefit from in-process electrical testing enabling early defect detection and process optimization. Integration with through-hole assembly operations ensures comprehensive coverage across mixed-technology products while maintaining production efficiency.

Data Management: Comprehensive data collection enables statistical analysis identifying trends and systematic issues. Integration with manufacturing systems provides real-time feedback supporting continuous improvement initiatives and quality enhancement across production operations.

Why Leading Brands Trust HILPCB for Electrical Testing

At HILPCB, electrical testing is not an optional service—it’s a core part of our manufacturing process. Every PCB we ship, from a 2-layer prototype to a complex HDI build, goes through strict electrical testing based on your design requirements and industry standards.

We do not modify or guess—we follow your netlist, impedance specs, and test points exactly as provided. Our job is to verify functionality, consistency, and reliability before your boards enter the next stage of production or assembly.

What sets us apart:

- ✅ 100% electrical testing on all orders, no matter the quantity

- ✅ Flying probe + fixture testing for both low and high volumes

- ✅ Impedance and high-speed testing for RF, microwave, and digital designs

- ✅ Experienced engineering support for test plan review and DFM feedback

- ✅ Detailed test reports for traceability and compliance documentation

With full in-house capabilities and tight process control, we help customers avoid costly defects, reduce field failure rates, and maintain a consistent standard across every batch—whether you're shipping to consumer markets or delivering into regulated sectors.

FAQ

What electrical defects can testing identify? Electrical testing detects open circuits, short circuits, component value deviations, and signal integrity degradation that could lead to field failures.

How does test coverage balance thoroughness with efficiency? Test coverage employs statistical analysis identifying critical measurement points while eliminating redundant testing for cost-effective coverage.

What determines electrical testing program complexity? Testing complexity depends on circuit density, frequency ranges, and reliability requirements. Complex systems demand comprehensive testing protocols.

Can electrical testing handle high-density assemblies? Modern systems handle high-density assemblies through advanced probing technologies, boundary scan implementation, and non-contact measurement techniques.

How do environmental factors affect testing accuracy? Professional facilities maintain controlled environments with temperature stability and electromagnetic shielding ensuring consistent measurement accuracy.