Highleap PCB Factory (HILPCB) delivers comprehensive PCB functional testing solutions designed for specialized substrate materials and complex assembly architectures. Our advanced FCT testing capabilities ensure optimal performance validation for high-frequency, multilayer, and specialty material PCBs while maintaining rapid production schedules and competitive pricing for global customers.

Advanced Functional Circuit Testing for Specialized Materials

PCB functional testing for specialized substrate materials requires sophisticated validation protocols that account for unique electrical characteristics and thermal properties inherent in advanced PCB technologies. Our expertise spans Rogers, ceramic, Teflon, and metal-core substrates where standard testing approaches prove inadequate.

Advanced Material Testing Technologies:

- High-Frequency Validation: Comprehensive S-parameter characterization and signal integrity analysis for Rogers PCB assemblies

- Thermal Management: Ceramic PCB testing incorporates thermal cycling and heat dissipation verification protocols

- Dielectric Characterization: Teflon PCB functional testing validates low-loss characteristics across operational frequency ranges

- Power Electronics: Metal core PCB testing includes thermal conductivity and electrical isolation verification

- Environmental Stress: Extended temperature, humidity, and vibration testing for mission-critical applications

- Parametric Analysis: Precision measurement of critical parameters including timing margins, power consumption, and signal quality metrics

- Real-Time Monitoring: Continuous parameter tracking during functional test execution identifying intermittent failures

- Custom Test Vectors: Application-specific stimulus patterns replicating actual operating conditions

- Impedance Control: Controlled impedance measurement for high-frequency PCB applications

Strategic Implementation: Our China PCB manufacturing facility utilizes advanced functional testing equipment specifically calibrated for specialized materials, ensuring accurate performance validation while maintaining cost-effectiveness and rapid turnaround times.

Complex Assembly Architecture Testing Solutions

Modern PCB designs incorporating multiple technologies and advanced packaging require sophisticated functional testing strategies addressing interconnection complexity, signal integrity, and system-level performance validation across diverse operating conditions.

Production Volume and Testing Strategies: High-volume manufacturing environments benefit from automated functional testing systems providing rapid test execution with excellent repeatability through custom test fixtures. These systems excel in standardized production scenarios where consistent board configurations enable fixture optimization and automated handling integration. Low-volume and prototype applications utilize flexible functional testing platforms offering superior adaptability without custom fixturing requirements, accommodating frequent design changes and varied board configurations.

Complex Assembly Testing Approaches: Rigid-flex PCB assemblies present unique testing challenges where mechanical flexibility and electrical connectivity must be validated simultaneously. Our specialized test fixtures accommodate dynamic flexing during functional verification while maintaining precise electrical contact throughout the testing sequence. HDI PCB designs benefit from boundary scan integration and micro-probing techniques enabling comprehensive functional validation without compromising high-density layout advantages.

Multi-Layer Validation Protocols: Complex multilayer PCB assemblies require systematic functional testing approaches verifying each layer's electrical performance while confirming proper interlayer connectivity and signal integrity. Power distribution network validation ensures stable voltage delivery across all power domains while ground plane integrity testing confirms proper EMI shielding and signal return path continuity.

Manufacturing Process Integration and Quality Control Systems

Functional testing integration within comprehensive quality management systems enables statistical process control, defect trend analysis, and continuous improvement initiatives that enhance manufacturing efficiency while maintaining consistent product quality standards.

Key Functional Testing Control Elements:

• Test Fixture Calibration: Daily verification procedures using reference standards ensuring measurement accuracy within specification tolerances • Environmental Control: Maintain temperature stability within ±1°C to prevent measurement drift. Implement humidity control and ESD protection measures to safeguard sensitive components • Test Program Validation: Comprehensive verification using known-good and defective boards confirming fault detection capability • Statistical Process Control: Real-time monitoring of test parameters with automated alerts for process drift detection • Defect Classification: Systematic categorization of failures enabling root cause analysis and process improvement targeting • Correlation Analysis: Comparison between functional testing results and downstream system validation confirming test program effectiveness • Data Management: Comprehensive recording and analysis of test results supporting traceability and quality documentation requirements • Equipment Maintenance: Preventive maintenance schedules and calibration protocols maintaining measurement integrity over time • Gerber viewer Integration: Design rule verification preventing testability issues during PCB development phases

Test Program Development and Optimization Strategies

Advanced Test Vector Generation and Simulation

Modern functional testing platforms enable sophisticated test program development through automated analysis of design data and component specifications. Our engineering team utilizes advanced simulation tools to generate comprehensive test vectors that exercise all critical circuit paths while optimizing test execution time. Application-specific stimulus patterns replicate real-world operating conditions ensuring accurate performance validation across the intended operational envelope.

Parametric Testing and Statistical Analysis

Effective functional testing programs extend beyond pass/fail validation to include detailed parametric characterization enabling process optimization and quality improvement initiatives. Statistical analysis of measurement data identifies trends indicating component drift, assembly process variations, or environmental effects that could impact long-term reliability. This data-driven approach enables proactive quality management and continuous improvement targeting.

Debug and Diagnostic Capabilities

Comprehensive functional testing systems provide detailed diagnostic information enabling rapid fault isolation and repair guidance when defects are detected. Advanced diagnostic algorithms analyze test results to identify probable failure modes and recommend corrective actions based on historical failure analysis databases. This diagnostic capability proves particularly valuable for SMT assembly operations where rapid defect resolution maintains production efficiency and minimizes rework costs.

Why Choose Highleap PCB Factory for Professional Functional Testing

As a leading China PCB factory, HILPCB delivers exceptional functional testing solutions backed by advanced equipment, experienced engineering support, and comprehensive quality management systems. Our China PCB manufacturing facility ensures optimal testing performance while maintaining competitive pricing and reliable delivery schedules.

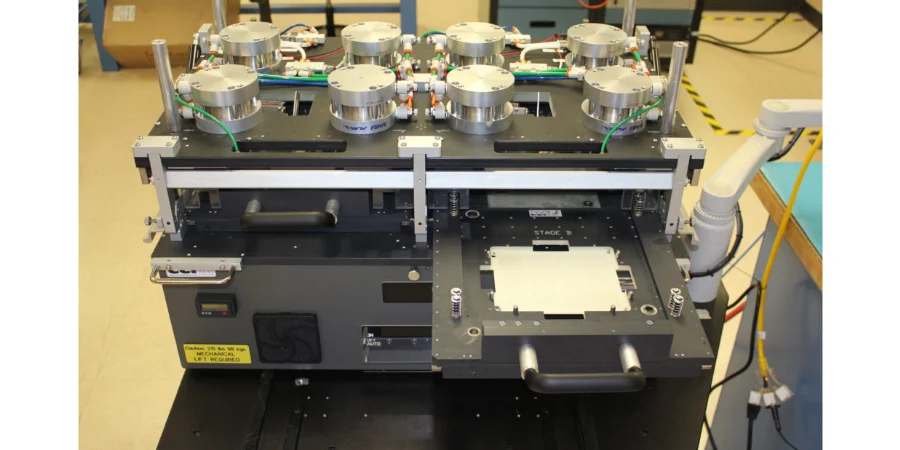

Advanced Testing Infrastructure: State-of-the-art functional testing equipment including precision automated test systems, environmental chambers, and specialized fixtures for complex assemblies. As a professional PCB manufacturer, we utilize automated handling systems, environmental control chambers, and comprehensive calibration protocols ensuring consistent testing quality across all production volumes and complexity levels.

Expert Engineering Support: Experienced test engineering team providing comprehensive program development, optimization consulting, and troubleshooting support. Our China PCB supplier capabilities include design for testability analysis, fixture development, and test coverage optimization enabling maximum fault detection while controlling testing costs and execution time requirements.

Integrated Quality Management: ISO 9001 certified China PCB manufacturing with comprehensive statistical process control, defect tracking, and continuous improvement programs. Complete integration between functional testing systems and broader quality management enables comprehensive traceability, automated reporting, and coordinated process optimization across manufacturing and assembly operations.

FAQ

What makes functional testing different from in-circuit testing approaches? Functional testing validates complete circuit operation under actual operating conditions while in-circuit testing focuses on individual component verification. FCT testing simulates real-world electrical environments ensuring the assembled PCB performs as intended in its target application, providing system-level validation that component-level testing cannot achieve.

How does specialized material testing differ from standard PCB validation? Specialized materials like Rogers, ceramic, and Teflon require customized test protocols accounting for unique electrical properties, thermal characteristics, and frequency response. Our testing equipment and methodologies are specifically calibrated for these materials ensuring accurate performance validation across their intended operating ranges.

What functional testing capabilities support high-frequency applications? High-frequency functional testing incorporates S-parameter measurement, signal integrity analysis, and impedance characterization using specialized test equipment with controlled impedance connections. Vector network analyzer integration enables comprehensive RF performance validation while maintaining signal fidelity throughout the measurement process.

Can functional testing accommodate rapid prototyping requirements? Our rapid prototyping functional testing services provide comprehensive validation within 24-48 hours of assembly completion. Flexible test program development and automated equipment enable quick turnaround while maintaining thorough performance characterization supporting accelerated development schedules.

How do environmental factors affect functional testing accuracy? Temperature, humidity, and vibration variations can impact measurement precision and circuit performance. Our controlled testing environment maintains stable conditions while environmental stress testing validates performance across operational ranges. Calibrated instrumentation and environmental monitoring ensure consistent results.

What quality standards govern functional testing programs? Functional testing programs follow industry standards including IPC guidelines, J-STD specifications, and application-specific requirements for automotive, medical, and aerospace sectors. Our quality management system ensures compliance with relevant standards while supporting customer-specific requirements and regulatory approval processes.