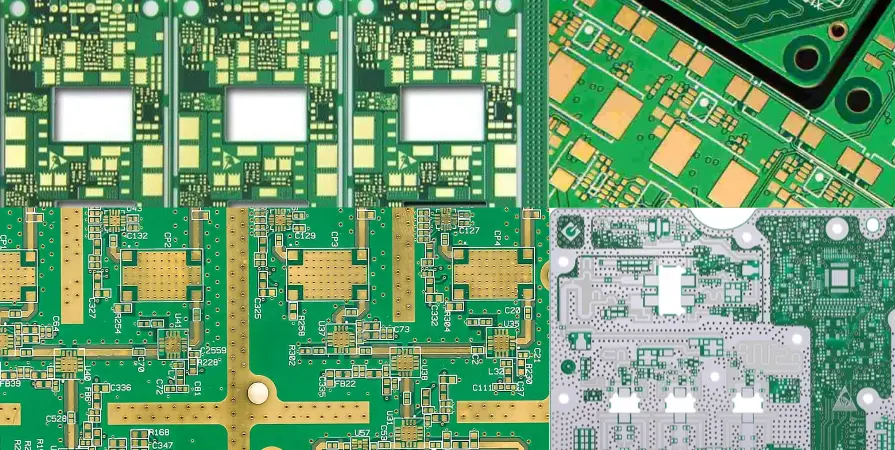

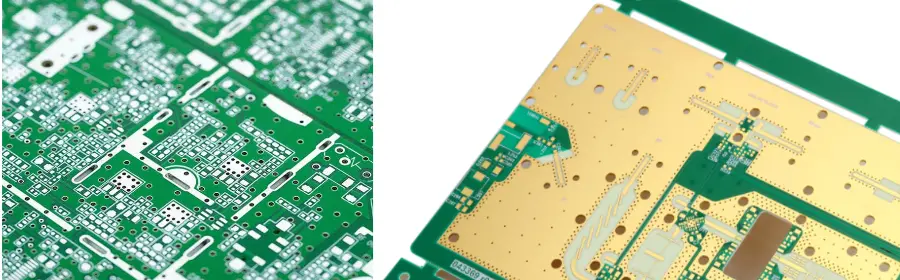

Highleap PCB Factory (HILPCB) provides comprehensive PCB manufacturing and assembly solutions featuring advanced PCB surface finish technologies. Our expertise spans traditional HASL to premium ENIG systems, delivering optimal surface treatments that protect copper traces from oxidation while ensuring reliable solderability across diverse applications and industries.

Core PCB Surface Finish Technologies and Performance

PCB surface finish serves as the critical protective interface between exposed copper conductors and component assembly, preventing oxidation while maintaining excellent solderability through metallic or organic coating applications.

Key Surface Finish Technologies:

- HASL (Hot Air Solder Leveling): Industry workhorse utilizing molten solder immersion at 250-275°C with 12+ month storage stability

- Lead-Free HASL: RoHS-compliant SAC alloy deposition providing robust solderability for standard SMT applications

- Surface Variation Impact: HASL creates 10-40 micrometer thickness variations limiting fine-pitch component compatibility

- ENIG (Electroless Nickel Immersion Gold): Premium dual-layer system with 3-6μm nickel + 0.05-0.23μm gold coatings

- Planarity Excellence: ENIG achieves ±5 micrometer flatness enabling 0.3mm pitch BGA assembly on HDI PCB designs

- High-Frequency Performance: Uniform ENIG thickness provides minimal signal loss for RF applications

- OSP (Organic Solderability Preservative): Chelating chemistry forming monomolecular copper protection layers

- Environmental Compliance: OSP offers lead-free solution with minimal thickness addition and excellent impedance control

- Storage Limitations: OSP requires controlled conditions with 6-month shelf life versus HASL/ENIG longevity

- Specialized Finishes: Immersion silver, tin, and ENEPIG address specific requirements for multilayer PCB applications

Strategic Selection Summary: Choose HASL for cost-effective standard applications, ENIG for fine-pitch and high-reliability requirements, and OSP for impedance-critical designs. Our China PCB manufacturing expertise ensures optimal PCB surface finish selection tailored to your specific performance requirements and budget constraints.

Surface Finish Selection Criteria and Application Matching

Strategic PCB surface finish selection requires comprehensive analysis of component requirements, environmental conditions, and cost constraints to optimize performance while controlling manufacturing expenses.

Component and Application Requirements: Fine-pitch BGA packages (≤0.4mm pitch) demand ENIG planarity for reliable assembly yields, while standard QFP and SOIC components (≥0.5mm pitch) perform excellently with cost-effective HASL finishes. Through-hole components benefit from HASL surface finish wetting characteristics, particularly in heavy copper PCB applications requiring enhanced current-carrying capacity. Automotive and industrial applications typically specify ENIG for extended reliability under harsh conditions, while consumer electronics utilize HASL or OSP for cost optimization.

Performance and Process Considerations: ENIG surface finish provides superior performance under temperature cycling, humidity exposure, and corrosive atmospheres due to nickel barrier protection and gold oxidation resistance. For high-frequency PCB applications, OSP offers minimal thickness addition preventing impedance discontinuities above 1 GHz, while ENIG maintains consistent thickness for controlled impedance requirements. HASL surface finish accommodates wide process windows and multiple reflow cycles for complex assemblies, though ENIG requires careful flux selection to prevent gold scavenging during assembly operations.

Cost Optimization and Strategic Selection: HASL typically costs 50-70% less than ENIG while providing adequate performance for standard applications, making cost-performance analysis critical for project success. Mixed PCB surface finish approaches enable optimization by applying premium finishes only to critical areas requiring enhanced performance characteristics. Our China PCB manufacturing expertise ensures optimal finish selection balancing your specific component requirements, operating environment, and budget constraints for maximum cost-effectiveness.

Manufacturing Process Control and Quality Assurance

Consistent PCB surface finish performance requires integrated quality management systems encompassing process monitoring, validation testing, and statistical control methodologies. Advanced manufacturing facilities implement comprehensive control systems ensuring finish quality while optimizing production efficiency.

Key Quality Control Elements:

• Temperature Precision: HASL solder pot temperature maintained within ±2°C for consistent coating characteristics • Contamination Monitoring: Copper content kept below 0.1% to prevent HASL surface finish degradation • Chemistry Management: Real-time monitoring of ENIG bath concentrations prevents black pad defects • Thickness Validation: X-ray fluorescence measurement ensures uniform PCB surface finish distribution • Solderability Testing: J-STD-003 protocols verify wetting performance before shipment • Accelerated Aging: Thermal cycling (-55°C to +125°C) and humidity testing validate long-term reliability • Statistical Control: Process capability indices above 1.67 maintained through automated monitoring • Visual Inspection: IPC-A-600 standards ensure cosmetic quality and defect detection • Gerber viewer Integration: Design rule verification prevents manufacturing issues during development

Cost Analysis and Economic Optimization

Cost Structures and Process Complexity

The choice of PCB surface finish has a direct impact on production cost, driven by material pricing and process complexity. HASL (Hot Air Solder Leveling) remains one of the most cost-efficient options, requiring minimal investment in materials and equipment. In contrast, finishes like ENIG (Electroless Nickel Immersion Gold) are significantly more expensive due to their use of precious metals and multi-step chemical processes—often costing two to four times more than HASL per unit area. Simpler finishes such as OSP (Organic Solderability Preservative) require less equipment and are easier to manage, making them attractive for budget-sensitive projects.

Production Volume and Economic Efficiency

Manufacturing scale plays a major role in surface finish economics. In high-volume production, the cost of more complex finishes like ENIG can be offset by automation, bulk material pricing, and process optimization. However, for low-volume or prototype runs, simpler finishes like HASL or OSP are typically favored due to their lower setup and inventory costs. Selecting the appropriate finish based on production volume helps manufacturers strike a balance between cost control and functional performance.

Lifecycle Costs and Strategic Finish Selection

While upfront costs are important, long-term reliability and lifecycle performance often justify investing in higher-end finishes. Applications in automotive, aerospace, and medical sectors commonly require ENIG due to its superior corrosion resistance and durability, reducing warranty claims and enhancing customer satisfaction. In some cases, mixed finish strategies are used—reserving ENIG for critical fine-pitch areas while applying cost-effective HASL elsewhere—maximizing both technical performance and economic efficiency.

Why Choose Highleap PCB Factory for Superior Surface Finishes

As a leading China PCB factory, HILPCB delivers exceptional PCB surface finish solutions backed by advanced manufacturing capabilities and comprehensive technical expertise. Our China PCB manufacturing facility ensures optimal surface treatment performance while maintaining competitive pricing and reliable delivery schedules.

Advanced Manufacturing Excellence: State-of-the-art production lines with automated HASL systems, precision ENIG processing, and controlled OSP chambers. As a professional PCB manufacturer, we utilize real-time monitoring systems ensuring consistent PCB surface finish quality while minimizing contamination risks across all surface treatment processes.

Complete Surface Finish Portfolio: Comprehensive range of PCB surface finish options including HASL, ENIG, OSP, and specialized finishes. Our China PCB supplier capabilities enable mixed finish applications, optimizing both performance and cost-effectiveness for diverse design requirements within single PCB assemblies.

Expert Technical Support & Quality Assurance: ISO 9001 certified China PCB manufacturing with experienced engineering support for design optimization and finish selection guidance. IPC-A-600 compliance and J-STD-003 testing protocols ensure consistent quality, while turnkey assembly integration provides coordinated PCB surface finish and assembly optimization.

FAQ

What determines the best PCB surface finish for my application? PCB surface finish selection depends on component pitch requirements, environmental conditions, and cost constraints. Fine-pitch components (≤0.4mm) require ENIG planarity, while standard SMT can use cost-effective HASL. Consider operating environment, shelf life needs, and assembly complexity when making selections.

How do surface finishes affect assembly yields and reliability? HASL surface finish provides robust solderability but thickness variations can affect fine-pitch assembly yields. ENIG surface finish offers excellent planarity improving fine-pitch yields but requires careful process control to prevent gold scavenging. OSP demands controlled handling and storage to maintain performance.

Can different surface finishes be mixed on one PCB? Yes, selective PCB surface finish application enables cost optimization by using appropriate finishes for specific areas. Common approaches include ENIG for fine-pitch components with HASL for standard connections, or OSP for impedance-critical sections with other finishes for power connections.

What are the shelf life differences between finishes? HASL surface finish provides 12+ month shelf life with proper storage. ENIG surface finish maintains excellent solderability for 12+ months with minimal degradation. OSP typically offers 6-month shelf life requiring controlled storage conditions to prevent degradation.

How do surface finishes impact signal integrity? Surface finish thickness and uniformity directly affect impedance control. ENIG surface finish provides consistent thickness minimizing impedance variations for high-frequency applications. HASL thickness variations can create impedance discontinuities above 1 GHz. OSP minimal thickness addition offers optimal impedance control.

What quality control measures ensure consistent results? Comprehensive PCB surface finish quality control includes real-time process monitoring, thickness measurement, solderability testing per J-STD-003, and accelerated aging validation. Statistical process control tracks critical parameters while automated inspection systems detect defects and ensure specification compliance.