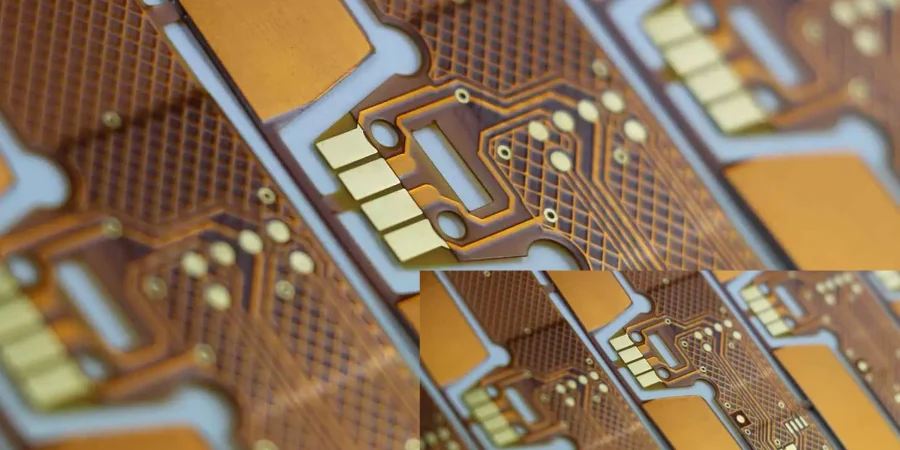

Modern electronic systems rely on materials that can withstand extreme heat, mechanical strain, and chemical exposure. Polyimide PCB technology meets these challenges with unmatched thermal endurance and mechanical flexibility, making it indispensable in aerospace, automotive, and medical electronics.

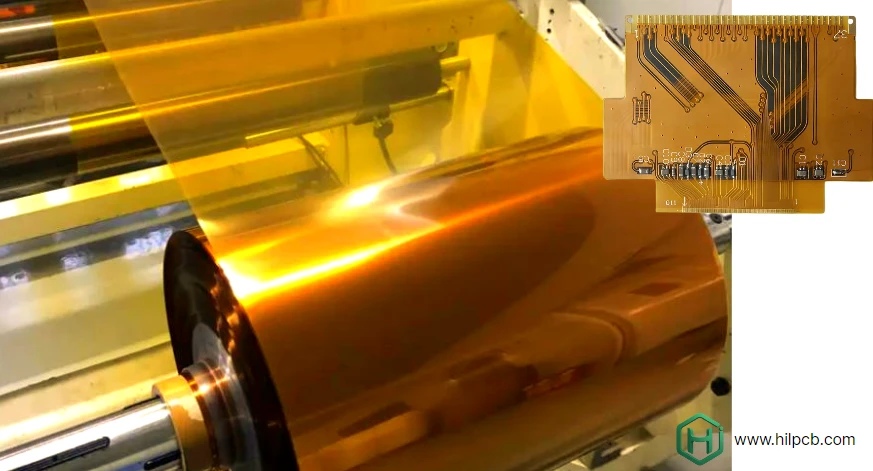

At HILPCB, we manufacture polyimide-based flexible circuit boards using advanced films such as DuPont Kapton®, UBE UPILEX®, Kaneka APICAL®, Taiwan-based Taimide®, and other high-reliability domestic polyimide films. Our engineering expertise ensures every circuit achieves stable performance under temperature swings, vibration, and long-term fatigue. From concept validation to mass production, we help engineers harness polyimide’s full potential in demanding applications.

Polyimide Chemistry and Structure

Polyimide's molecular structure creates unique properties distinguishing it from other flexible circuit substrates. Understanding material science informs appropriate application and processing.

Molecular Architecture Polyimide polymers consist of imide groups linked by aromatic rings creating rigid, thermally stable structures. This molecular arrangement provides exceptional thermal resistance—operating range from -200°C to +300°C continuously without degradation. Glass transition temperature exceeds 360°C, maintaining dimensional stability during soldering and assembly.

Aromatic rings contribute chemical resistance. Polyimide withstands most acids, bases, solvents, and oils without swelling or dissolution. This inertness suits FPC boards for harsh industrial and automotive environments where chemical exposure occurs.

Mechanical Properties Tensile strength exceeding 230 MPa enables thin films (12.5-50μm) supporting circuit patterns without tearing. Elongation at break reaches 70%, allowing tight bend radii without cracking. Unlike rigid materials becoming brittle at low temperatures, polyimide maintains ductility to -200°C preventing cold-temperature failures.

Coefficient of thermal expansion (CTE) ranges 12-20 ppm/°C, lower than copper (17 ppm/°C) but higher than rigid FR4 materials. This mismatch requires consideration in multilayer constructions to prevent delamination during thermal cycling.

Polyimide Film Types and Selection

Different polyimide formulations offer varying properties optimizing performance for specific applications. Selecting appropriate grade balances cost against requirements.

Standard Polyimide (Kapton HN) Industry workhorse providing excellent overall properties. Operating range -200°C to +300°C suits most flexible PCB applications. Dielectric constant 3.4 at 1 MHz supports standard digital signals. Moisture absorption 2.5% affects dimensional stability in humid environments. Cost-effective for consumer electronics and industrial applications.

High-Performance Polyimide (Kapton E, UPILEX-S) Enhanced dimensional stability and lower moisture absorption (1.4%) suit fine-pitch circuits and high-reliability applications. Tighter CTE control maintains registration accuracy in multilayer constructions. Superior tear resistance improves handling during manufacturing. Higher cost justified for aerospace, medical, and military applications.

Low-CTE Polyimide Specialized grades match CTE to copper, minimizing stress during thermal cycling. Critical for high-layer-count flex boards experiencing wide temperature ranges. Aerospace and automotive applications benefit from improved reliability through thermal cycles.

Transparent Polyimide Optical clarity enables applications requiring visual inspection through substrate. LED arrays and display backlighting utilize transparent polyimide. Lower thermal performance limits applications to moderate temperature ranges.

Thermal Performance in Extreme Environments

Polyimide PCBs enable electronics in temperature extremes impossible for standard materials. Understanding thermal behavior ensures reliable designs.

High-Temperature Operation Continuous operation at +200°C and peaks to +300°C suit under-hood automotive electronics, aerospace systems, and industrial process control. At +150°C continuous operation, polyimide maintains mechanical properties while standard FR4 begins degrading around +130°C glass transition.

Soldering compatibility allows multiple reflow cycles without damage. Lead-free soldering at 260°C peak causes no polyimide degradation. High glass transition temperature prevents warping during assembly. Surface mount and through-hole assembly processes proceed normally.

Cryogenic Performance Polyimide maintains flexibility and electrical properties to -200°C. Aerospace applications experiencing -55°C at cruise altitude, oil and gas downhole sensors at -40°C, and cryogenic instrumentation rely on polyimide's low-temperature ductility. Materials becoming brittle in cold fracture during vibration or handling; polyimide remains flexible.

Thermal Cycling Reliability Daily temperature swings from -40°C to +125°C in automotive applications create mechanical stress through CTE mismatch. Proper flexible PCB design with stress relief features and appropriate copper weights accommodates expansion differences. Testing includes 1000+ thermal shock cycles validating long-term reliability.

Chemical and Environmental Resistance

Polyimide's chemical inertness enables flexible circuits in environments destroying other materials. Understanding resistance limitations prevents failures.

Chemical Compatibility Polyimide resists most chemicals including:

- Acids: Sulfuric, hydrochloric, nitric (except hot concentrated)

- Bases: Sodium hydroxide, ammonium hydroxide

- Solvents: Acetone, alcohols, ketones

- Oils and fuels: Gasoline, diesel, hydraulic fluids

- Cleaning agents: Isopropyl alcohol, flux removers

Limited resistance to strong bases at elevated temperatures. Avoid prolonged exposure to concentrated sodium hydroxide above +80°C.

Moisture Resistance Standard polyimide absorbs 2.5% moisture at equilibrium affecting dimensional stability. Design tolerances must accommodate 0.2-0.3% dimensional change in high-humidity environments. High-performance grades reduce absorption to 1.4% improving stability.

Moisture absorption reversible—drying restores original dimensions. Baking at +120°C for 2 hours before soldering drives out absorbed moisture preventing popcorning during reflow.

Radiation Resistance Gamma radiation sterilization (medical devices) and space radiation exposure cause minimal polyimide degradation. Doses exceeding 100 Mrad tolerated without significant property changes. This enables medical device sterilization and aerospace applications in radiation environments.

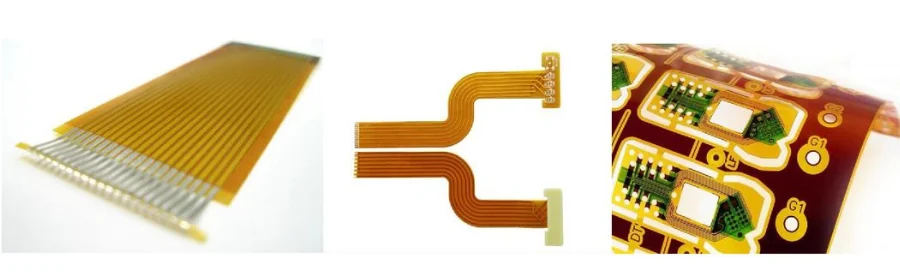

Polyimide PCB Applications and Design Considerations

Polyimide PCBs are not limited to high-temperature environments—they are the foundation for performance-critical systems requiring electrical stability, lightweight structure, and long-term reliability. Proper design ensures polyimide’s material advantages translate into durable real-world performance.

Key Application Fields

- Aerospace avionics, satellite systems, and instrumentation

- Automotive sensors, engine control units, and EV battery monitoring

- Medical devices such as implantable electronics and sterilizable tools

- Industrial automation and power control systems

- Flexible and rigid-flex assemblies in consumer and wearable electronics

Design Optimization Guidelines

- Match copper thickness to flexing frequency; use thinner copper (½ oz) for dynamic regions.

- Maintain symmetrical stack-up to balance thermal expansion and avoid warpage.

- Add stiffeners beneath connectors or components to reduce stress concentration.

- Bake polyimide circuits before assembly to remove absorbed moisture and prevent delamination.

- Consider controlled-impedance designs for high-speed or RF applications requiring stable dielectric properties.

By integrating these design rules, engineers maximize the longevity and electrical stability of polyimide-based circuits in harsh conditions.

HILPCB — Polyimide PCB Manufacturing Excellence

HILPCB combines material science expertise with precision manufacturing to deliver Polyimide PCB solutions that perform where standard boards fail. We process all major polyimide grades using specialized handling, registration, and lamination techniques that maintain ±0.05 mm accuracy even through extreme thermal cycles.

Our testing protocols—thermal shock, flex-cycle, and chemical exposure—validate each circuit’s performance under real operating conditions. With traceable material certifications and quality systems aligned to medical, automotive, and aerospace standards, HILPCB ensures each build meets the highest reliability criteria.

Partnering with HILPCB means more than access to premium materials—it’s an engineering collaboration that transforms specifications into proven results. Whether you need prototypes or volume production, our technical team supports every stage of your Polyimide PCB development with speed, precision, and confidence.

Frequently Asked Questions

Q1: Why is polyimide used for flexible PCB instead of other materials? Polyimide offers unmatched combination of thermal stability (-200°C to +300°C), mechanical flexibility, chemical resistance, and electrical properties. Alternative materials (PET, PEN) have narrower temperature ranges and inferior thermal stability. Polyimide's unique property balance makes it the gold standard.

Q2: Can polyimide PCBs survive lead-free soldering temperatures? Yes, polyimide easily withstands 260°C peak reflow temperatures required for lead-free soldering. Multiple reflow cycles possible without degradation. High glass transition temperature (+360°C) prevents warping during assembly. Standard SMT assembly processes applicable without modification.

Q3: How does moisture affect polyimide PCB dimensions? Standard polyimide absorbs approximately 2.5% moisture causing 0.2-0.3% dimensional change. Design tolerances must accommodate this variation in humid environments. High-performance grades reduce absorption to 1.4%. Baking before soldering (120°C, 2 hours) removes absorbed moisture.

Q4: What thickness polyimide should I specify for my flex PCB? Choose 12.5-25μm for maximum flexibility in ultra-thin applications (wearables, implantables). Specify 25-50μm for standard flexible circuits balancing flexibility with handling strength. Use 75-125μm when rigidity needed for stiffener-free component mounting areas. Thinner films require more careful handling during manufacturing.

Q5: Is polyimide suitable for high-frequency RF applications? Yes, polyimide's consistent dielectric constant (3.4 at 1 MHz) and low loss tangent (0.002) suit RF applications through microwave frequencies. Stable electrical properties across temperature range maintain impedance control. Specialized low-loss grades available for demanding millimeter-wave applications.