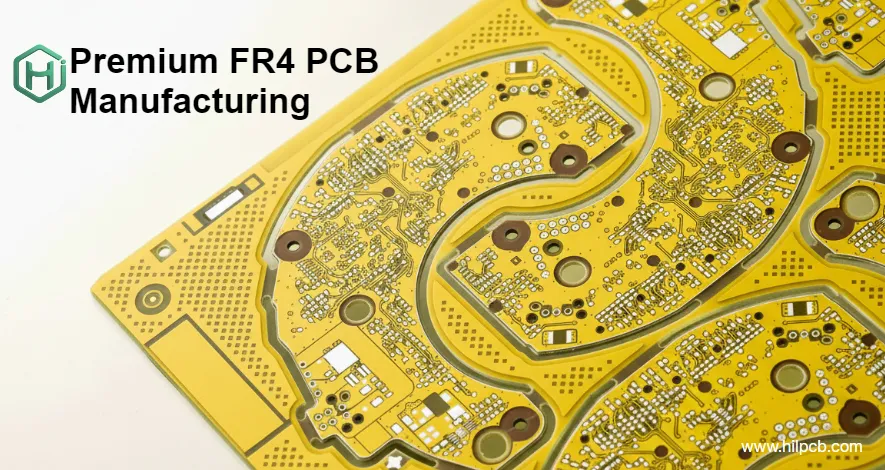

As electronic devices demand higher speeds, smaller footprints, and greater reliability, PCB materials play a decisive role in long-term performance. Premium FR4 PCBs combine high-Tg resin systems, low dielectric loss, and excellent mechanical stability—making them ideal for industrial, automotive, and communication electronics.

At HILPCB, we are a comprehensive PCB manufacturer producing all board types—from multilayer PCB and rigid-flex PCB to high-frequency PCB and high-speed PCB. Our engineering team focuses on advanced process optimization and reliability assurance across every PCB category.

Understanding the Advantages of Premium FR4 Materials

Premium FR4 is an upgraded glass-reinforced epoxy laminate with enhanced thermal and electrical performance. Unlike standard FR4 PCB materials, premium FR4 substrates offer:

- High glass transition temperature (Tg ≥ 170°C) for better thermal endurance

- Low Z-axis expansion (<3%) to prevent via cracking during reflow

- Dielectric constant stability (±2%) across temperature and frequency ranges

- Reduced moisture absorption (≤0.1%), extending product lifetime

- Low Df (<0.015) for high-speed signal integrity

These attributes make premium FR4 suitable not only for general electronics but also for applications that overlap with high-frequency and high-speed PCB manufacturing, where signal stability and material reliability are critical.

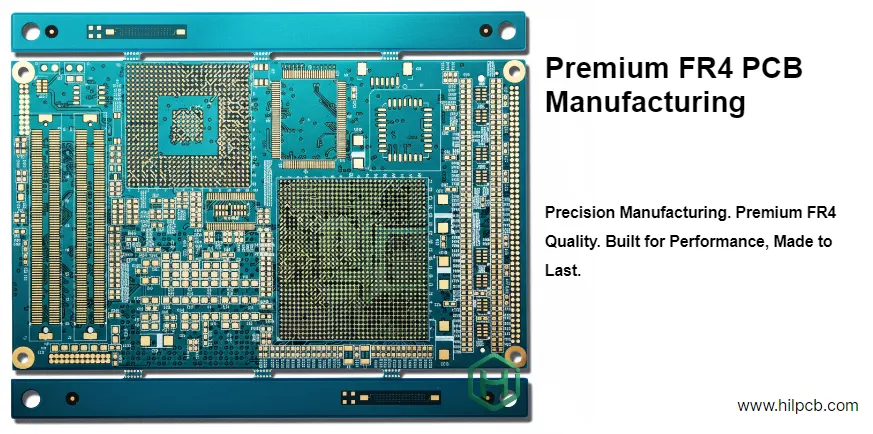

Advanced Manufacturing and Process Control

Producing premium FR4 PCBs requires precision process control and experience in advanced PCB fabrication. HILPCB’s facilities integrate automated lamination, fine-line imaging, and AOI inspection systems to ensure consistency and high yield.

Key process capabilities include:

- Controlled lamination temperature (±2°C uniformity) for consistent Tg performance

- Laser drilling and microvia formation for HDI and complex multilayer PCB designs

- Tight impedance control (±5%) through dielectric calibration

- Post-lamination stress relief baking for dimensional stability

- ENIG, OSP, or immersion silver surface finishes for long-term solderability

We also support hybrid stack-ups, combining FR4 with low-loss materials for optimized signal and thermal behavior—ideal for high-speed communication modules and RF boards.

Thermal Stability and Reliability in High-Density Designs

Thermal management is a key factor in premium FR4 PCB performance.

Excess heat during operation or reflow can degrade resin bonds, reduce reliability, or cause warpage. HILPCB’s engineering approach includes:

- Thermal simulation and DFM evaluation based on Gerber and stack-up data

- Copper plane optimization for efficient heat spreading

- High-conductivity laminates for power-dense circuits

- Rigid-flex thermal routing to move heat away from sensitive IC zones

These strategies ensure each PCB maintains thermal stability and electrical integrity under high load, making premium FR4 ideal for automotive control units, power modules, and LED lighting systems.

Quality Control and Reliability Testing

To guarantee consistent performance, every premium FR4 PCB is validated through our in-process quality control system:

- Automated Optical Inspection (AOI) and X-ray verification

- Cross-section analysis for plating uniformity and via reliability

- Thermal shock testing (-55°C to +125°C, 500 cycles)

- HAST and CAF resistance testing under 130°C/85% RH conditions

Combined with statistical process control (SPC) and full traceability, these tests ensure compliance with IPC Class 3 and automotive-grade reliability standards.

Cost Efficiency and Material Optimization

Although premium FR4 materials have a higher base cost, engineering-driven stack-up design significantly improves ROI. We use selective layer application, integrating premium cores only where thermal or mechanical stress is critical, while employing standard layers or single-double-layer PCB for secondary circuits.

This hybrid approach reduces overall cost by 20–30% without sacrificing performance.

Additionally, clients benefit from rapid prototyping through small batch assembly before scaling up to large volume assembly.

HILPCB’s Comprehensive Manufacturing Capabilities

As a full-service PCB manufacturer, HILPCB delivers more than FR4 fabrication.

Our portfolio includes high-Tg, HDI, halogen-free, heavy copper, Teflon, and metal-core PCBs, with full in-house SMT assembly and turnkey assembly support.

From prototype verification to mass production, we ensure tight process control, consistent quality, and reliable delivery—empowering global customers in automotive, telecom, aerospace, and industrial sectors.