Speed to market often determines product success in today's competitive electronics landscape. When a wearable device startup approached us with their rigid flex board design, they had just 8 weeks to deliver working prototypes for a major investor demonstration. Their previous manufacturer quoted 6-week lead time for prototypes alone—making their deadline impossible.

We delivered 10 fully assembled rigid flex boards in 12 days, complete with components and functional testing. The startup secured $2.3 million in funding at their demonstration. Fast turnaround isn't just about convenience—it's about capturing market opportunities when they appear.

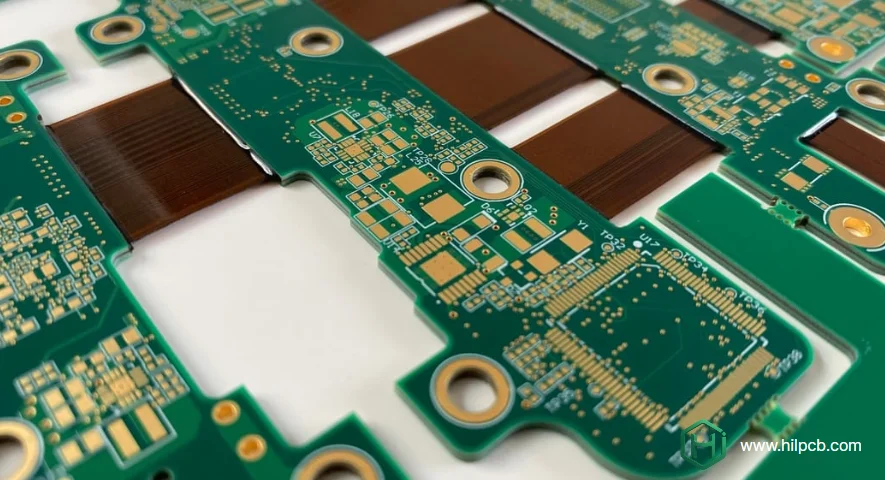

At HILPCB, we specialize in rapid custom rigid flex board manufacturing from prototype through production volumes, combining HDI PCB expertise with flexible circuit capabilities to meet aggressive timelines without compromising quality.

Rapid Prototyping Capabilities

Traditional rigid flex board manufacturers struggle with prototypes because their processes optimize for production volumes. Tooling designed for 10,000-unit runs doesn't adapt well to 5-piece prototype orders. We maintain dedicated prototype lines specifically configured for quick-turn, low-volume manufacturing.

Standard Prototype Timeline: 12-15 Days

Most rigid flex board prototypes ship within 12-15 days from design approval. This includes complete fabrication, quality inspection, and shipping. For urgent projects, express service delivers in 8-10 days. Compare this to industry average of 3-4 weeks for rigid flex prototypes.

What enables faster turnaround? Our facility maintains inventory of common rigid flex materials including standard polyimide films, coverlay materials, and various laminate options. When your design arrives, we don't wait for material orders—production starts immediately. Material procurement typically adds 5-7 days to competitor timelines.

Design Verification Before Production

Fast turnaround means nothing if boards arrive defective. Every custom rigid flex board design receives engineering review before fabrication begins. Our DFM (Design for Manufacturability) analysis catches issues that would cause problems during production:

A medical device manufacturer submitted rigid flex board design with 0.1mm traces in flex regions requiring 10,000+ flex cycles. Our engineering review flagged this immediately—0.1mm traces in dynamic flex areas rarely survive even 1,000 cycles. Increasing to 0.15mm traces and optimizing the layer stack-up added just $1.20 per board while ensuring reliability. Catching this before prototype production saved the entire prototype budget.

Volume Production Scalability

Prototype success is just the beginning. Most projects need smooth transition from prototype to production volumes without design iteration or qualification delays. Our manufacturing approach supports this progression naturally.

Consistent Process From Prototype to Production

We use identical processes and materials for prototypes and production. The rigid flex board you validate during prototyping performs exactly the same in production because nothing changes—same equipment, same materials, same operators, same quality controls.

A consumer electronics company learned this lesson after prototyping at one factory and moving to different manufacturer for production. Their "cost-optimized" production supplier used different polyimide material, different adhesive system, and different lamination process. First production batch had 18% failures during flex cycle testing. Redesigning and requalifying cost $45,000 and delayed product launch 3 months.

Volume Pricing Structure

Rigid flex board pricing decreases significantly with volume:

- Prototypes (5-10 pieces): $80-250 per design, depending on complexity

- Pilot Production (50-200 pieces): $25-75 per board

- Low Volume (500-2,000 pieces): $12-35 per board

- Production (5,000-50,000 pieces): $6-18 per board

- High Volume (100,000+ pieces): $3-12 per board

These ranges reflect typical 4-6 layer rigid flex designs. More complex assemblies or specialized materials adjust pricing accordingly. Our small batch assembly services bridge the gap between prototype and full production, enabling gradual volume ramps without minimum order penalties.

Complete Assembly Services

Finding separate suppliers for PCB fabrication and assembly creates unnecessary complexity. When rigid flex boards ship to assembly houses unfamiliar with flexible circuit handling, damage rates increase dramatically. We provide complete rigid flex board assembly services specifically optimized for flexible circuit construction.

Specialized SMT Assembly for Rigid Flex

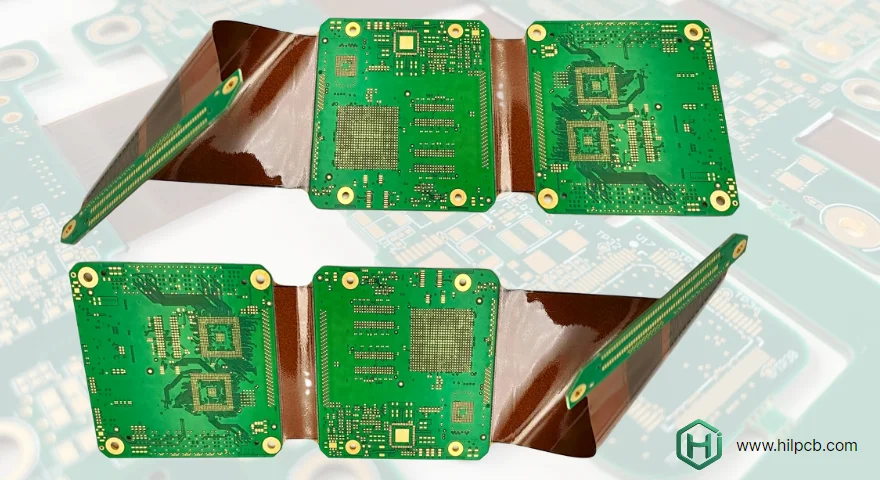

Rigid flex boards cannot run through standard SMT assembly lines without modification. The flexible sections require support during component placement and reflow to prevent warping and component misalignment. Our SMT lines use custom fixturing designed for rigid flex geometries.

Component placement near rigid-flex transitions requires special attention. Standard pick-and-place programming doesn't account for the step change in board height at transition zones. Our programming team creates custom placement routines ensuring accurate component positioning even at transition boundaries.

Thermal Profiling for Mixed Materials

Reflow soldering rigid flex boards requires careful thermal management. Rigid sections using high-speed PCB materials have different thermal mass than flexible polyimide sections. Standard reflow profiles create temperature gradients that can damage sensitive areas.

We develop custom thermal profiles for each rigid flex design, monitoring temperature at multiple points across rigid and flexible sections. This ensures proper solder joint formation in all areas while protecting temperature-sensitive materials and components. Our profiling capability has prevented countless field failures from cold solder joints or heat-damaged components.

Complete Turnkey Solutions

Beyond assembly, we handle:

- Component sourcing and procurement (preview BOM using our BOM viewer tool before submission)

- Custom tooling and fixture design

- Programming and functional testing

- Conformal coating and environmental protection

- Final packaging and labeling

This integrated approach enables true turnkey delivery—submit your design and receive finished, tested assemblies ready for integration into your product. Many customers move from design concept to working product in under 4 weeks using our complete large volume assembly capabilities.

Quality Certifications and Standards

Custom rigid flex board manufacturing for medical, aerospace, and automotive applications requires verified quality management systems and complete traceability. Our facility maintains certifications supporting the most demanding industry requirements.

ISO Certifications

- ISO 9001:2015: Quality management systems for all manufacturing operations

- ISO 13485: Medical device quality management and regulatory compliance

- IATF 16949: Automotive quality management and production part approval processes

- AS9100: Aerospace quality standards and first article inspection requirements

These certifications aren't just wall decorations—they represent documented processes controlling every aspect of rigid flex board manufacturing from incoming materials through final shipping. Certification audits verify our compliance annually.

Material Traceability

Every material used in your rigid flex board gets tracked from receiving through delivery. Lot numbers for laminates, polyimide films, adhesives, coverlay materials, and components maintain complete genealogy. If any field issue occurs, we can trace back to specific material lots, production dates, operators, and equipment used.

This traceability enables rapid root cause analysis and targeted corrective actions. When a medical device customer discovered reduced flex life in one production batch, our traceability system identified the issue within hours: a single lot of coverlay adhesive had different properties than specification. We isolated affected boards, implemented corrective actions, and prevented recurrence—all within 48 hours.

Testing and Validation

Beyond electrical testing, we perform comprehensive mechanical validation:

- Flex Cycle Testing: Dynamic flexing to specified cycle counts at specified bend radius

- Temperature Cycling: -55°C to +125°C for automotive and aerospace applications

- Humidity Testing: 85°C/85% RH exposure for long-term reliability

- Mechanical Shock: Drop testing and vibration exposure

- Functional Testing: Application-specific validation of assembled boards

Working With HILPCB

Simple Order Process

Getting started with custom rigid flex board manufacturing is straightforward:

- Submit Design: Upload Gerber files or design package through quote request page

- Engineering Review: Receive DFM analysis within 4-8 hours identifying any issues

- Quote Approval: Review detailed quote covering prototype and production pricing

- Production: Manufacturing begins immediately upon approval

- Quality Verification: All boards inspected and tested before shipping

- Delivery: Express shipping included for most orders

Design Support Available

First-time rigid flex designers often need guidance. We provide:

- Stack-up recommendations based on your flexibility requirements

- Transition zone design review and optimization

- Material selection for your operating environment

- Component placement recommendations

- Assembly feasibility analysis

Submit your design concept or existing PCB layout through quote request—our engineering team provides consultation on converting to rigid flex construction.

Long-Term Partnership

Many customers start with single prototype order and grow to regular production volumes over time. We support this progression through:

- Consistent pricing structure as volumes increase

- Design for manufacture improvements at each stage

- Component obsolescence management and alternatives

- Inventory management for repeat orders

- Dedicated account support for production customers

Frequently Asked Questions - Custom Rigid Flex Board Manufacturing

Q1: What is minimum order quantity for custom rigid flex boards?

We have no minimum order quantity. Single prototypes to millions of units—we handle all volumes. Most customers start with 5-10 prototypes for validation before moving to production. Pricing naturally favors larger quantities, but prototype orders don't carry unreasonable minimums or setup fees.

Q2: How fast can you deliver rigid flex board prototypes?

Standard prototype turnaround: 12-15 days from design approval to delivery. Express service: 8-10 days for urgent projects. This includes complete fabrication, inspection, and shipping. Add 3-5 days if assembly required. Our fast turnaround comes from maintaining material inventory and running dedicated prototype lines.

Q3: Can you assemble components on rigid flex boards?

Yes, we provide complete assembly services including SMT, through-hole, custom fixturing, thermal profiling, and functional testing. Our assembly processes specifically optimize for rigid flex construction, preventing damage to flexible sections during component placement and reflow. Turnkey assembly available from bare board through tested, packaged final product.

Q4: What quality certifications do you maintain?

We hold ISO 9001:2015 (quality management), ISO 13485 (medical devices), IATF 16949 (automotive), AS9100 (aerospace), and IPC-A-610 Class 3 (workmanship) certifications. All certifications verified through annual third-party audits. Complete material traceability and process documentation available for regulated industries.

Q5: How does pricing work for custom rigid flex boards?

Pricing depends on layer count, flexible area percentage, materials, and quantities. We provide detailed quotes showing: prototype pricing (5-10 pieces), pilot production (50-200 pieces), low volume (500-2,000 pieces), and production volumes (5,000+ pieces). Quote includes both fabrication and assembly if required. Most designs see 60-75% cost reduction from prototype to production pricing.