Finding the right rigid flex PCB manufacturer determines whether your product succeeds or fails in the field. Unlike standard PCB manufacturing, rigid-flex production requires specialized equipment, material expertise, and process control that most factories claim but few actually deliver.

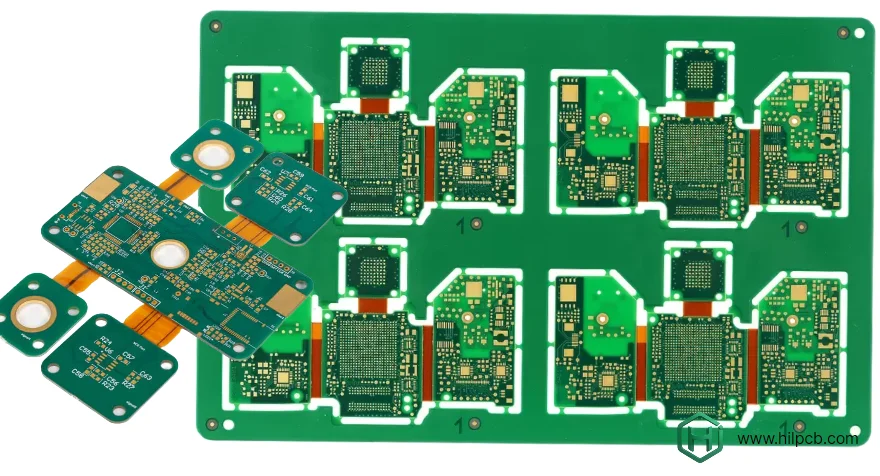

At HILPCB, we manufacture rigid flex PCBs for applications where reliability matters—from medical implantables to aerospace systems. Our complete in-house capabilities handle everything from multilayer PCB fabrication to SMT assembly, ensuring consistent quality from design to delivery.

Why Choosing the Right Manufacturer for Rigid Flex PCB Production is Critical

Rigid flex PCB production requires advanced techniques and specialized equipment to meet the demands of modern electronics. As the technology integrates both rigid and flexible elements, ensuring high reliability across both sections is critical. Whether it’s for medical devices, automotive systems, or wearables, a reliable rigid flex PCB manufacturer can make the difference between success and failure in the field.

Key elements of our expertise in Rigid Flex PCB manufacturing include:

- Advanced lamination and process control to ensure precise bonding between rigid and flexible layers, preventing mechanical stress at the transition zones

- Optimized material selection with adhesive and adhesiveless polyimide constructions to balance durability, performance, and cost based on your specific application

- High-density interconnect (HDI) technology for complex routing and maintaining signal integrity in compact spaces

- Custom tooling and fixturing for flexible section assembly, ensuring accurate component placement without distortion

- Dedicated testing and validation including dynamic flex testing, impedance verification, and temperature cycling to meet industry-specific requirements

- Comprehensive design support with DFM (Design for Manufacturability) reviews to optimize your design for reliability and cost-efficiency

By employing these strategies, we ensure that your rigid flex PCBs perform reliably, reduce failure rates, and meet demanding industry standards. Our expertise guarantees high-quality production from prototype to large-scale manufacturing, helping your products succeed in the market with enhanced durability and functionality.

Complete In-House Rigid Flex PCB Capabilities

Manufacturing quality rigid flex PCBs requires controlling every production step under one roof. When fabrication and assembly happen at different facilities, quality suffers and lead times extend significantly.

Our integrated manufacturing facility handles:

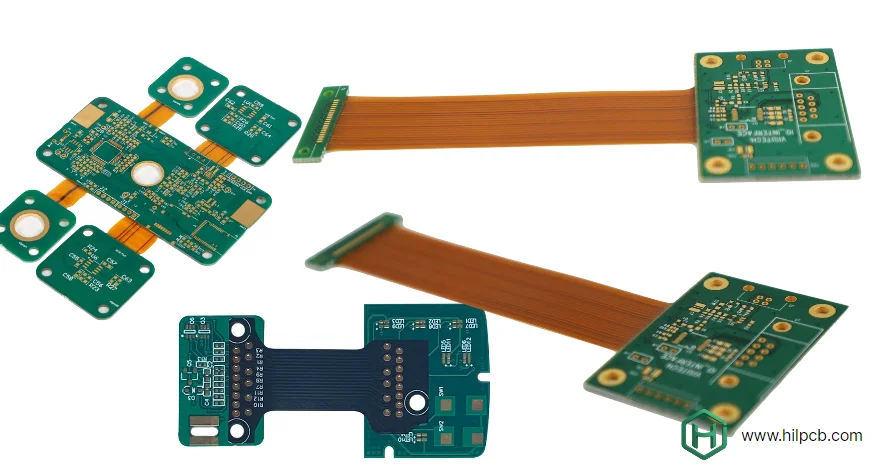

Rigid Section Fabrication We produce the rigid PCB sections using advanced HDI PCB technology supporting up to 32 layers with 0.1mm microvias. This enables complex routing in compact spaces while maintaining signal integrity for high-speed applications.

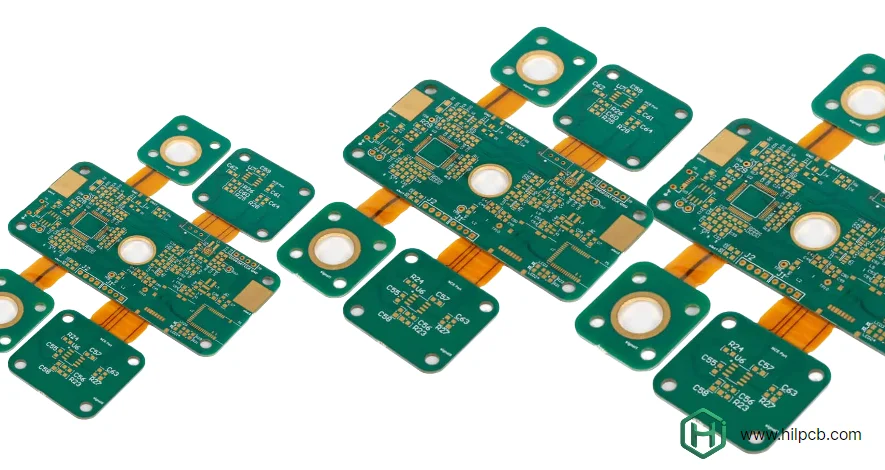

Flexible Circuit Production The flexible sections utilize rolled-annealed (RA) copper for superior flex life and low-loss flex PCB substrates for optimal electrical performance. We maintain inventory of both adhesive and adhesiveless polyimide materials to optimize cost and reliability based on your application requirements.

Precision Lamination Our dedicated rigid-flex lamination presses use controlled heating profiles optimized for polyimide materials. Precise pressure distribution prevents resin starvation at transitions while avoiding excessive flow that can damage flex circuits. Temperature monitoring at multiple points ensures uniform heat distribution across the entire panel.

Quality Verification Every rigid flex board undergoes comprehensive testing including electrical continuity, impedance verification, and flex cycle validation. For dynamic applications, we perform actual bend testing to your specified cycle requirements before shipping production quantities.

Rigid Flex PCB Design Support and Engineering Services

Most rigid flex failures originate in the design phase, not manufacturing. That's why we provide comprehensive engineering support before production begins.

Our free DFM (Design for Manufacturability) review identifies potential issues early:

A consumer electronics manufacturer submitted a 6-layer rigid flex design for a wearable device. Our engineering review identified that repositioning two components and adjusting the stack-up could reduce layer count to 4 layers—cutting per-unit cost from $18.50 to $11.80 while improving reliability. The design change took two days to implement but saved over $65,000 annually at their production volume.

Design Review Includes:

- Stack-up optimization for your specific application requirements

- Transition zone geometry verification using FEA stress analysis

- Bend radius calculations ensuring reliability over product lifetime

- Material recommendations based on environmental conditions

- Component placement review identifying potential assembly issues

- Cost reduction strategies maintaining full functionality

You can preview your Gerber files using our Gerber viewer tool before submitting for quote, though design files for quotes and DFM analysis must be uploaded through our quote request page.

Rigid Flex PCB Assembly and Turnkey Manufacturing

Finding separate suppliers for PCB fabrication and assembly creates unnecessary complexity, extends timelines, and introduces quality risks. We provide complete turnkey assembly services specifically optimized for rigid flex construction.

Specialized Handling Requirements Rigid flex PCBs cannot be assembled using standard PCB processes. The flexible sections require custom fixturing during component placement to prevent board distortion. Our SMT lines use specialized tooling designed for rigid-flex geometries, ensuring components get placed accurately even near transition zones.

Reflow profiling for rigid flex boards requires careful attention to thermal gradients. The different thermal masses of rigid and flexible sections can create temperature variations during reflow. Our profiling engineers develop custom thermal profiles for each rigid flex design, ensuring proper solder joint formation without damaging polyimide materials.

Complete Assembly Services

- Component sourcing and procurement management

- Custom tooling and fixturing for rigid flex geometries

- Precision SMT assembly supporting 0201 components

- Through hole assembly when required

- Conformal coating and environmental protection

- Final functional testing and inspection

For projects requiring enclosure integration, our box build assembly services complete your product from PCB through final packaged unit.

Quality Standards and Certifications

Medical, aerospace, and automotive applications demand verified manufacturing processes and complete traceability. Our facility maintains certifications supporting the most demanding industry requirements.

Quality Management Systems:

- ISO 9001:2015 for quality management

- ISO 13485 for medical device manufacturing

- IATF 16949 for automotive electronics

- AS9100 for aerospace applications

- IPC-A-610 Class 3 workmanship standards

Material Traceability Every material used in rigid flex PCB production gets tracked from receiving through final shipment. Lot numbers for laminates, polyimide films, adhesives, and components maintain complete traceability. This enables rapid root cause analysis if any field issues occur and ensures regulatory compliance for medical and aerospace applications.

Testing and Validation Beyond standard electrical testing, we perform application-specific validation:

- Dynamic flex testing to specified cycle counts

- Temperature cycling (-55°C to +125°C)

- Humidity exposure testing

- Mechanical stress analysis

- Impedance verification for high-speed PCB requirements

Frequently Asked Questions - Rigid Flex PCB Manufacturing

Q1: What is minimum order quantity for rigid flex PCB?

We have no minimum order quantity for rigid flex PCBs. Single prototypes to production volumes of 100,000+ units—we handle projects of all sizes. Pricing naturally favors larger quantities, but small prototype orders aren't penalized with unreasonable minimums. Most customers start with 5-10 prototypes for validation before proceeding to production.

Q2: How much does rigid flex PCB manufacturing cost?

Pricing depends on layer count, flex area percentage, materials, and quantities. Typical ranges: Prototypes (5 pieces): $80-300 per design. Low volume (100-500 pieces): $12-45 per unit. Production (2,000+ pieces): $6-20 per unit. We provide detailed quotes showing exactly how design parameters affect cost, often identifying 20-30% savings through optimization.

Q3: What are lead times for rigid flex PCB manufacturing?

Standard rigid flex PCB prototype lead time: 12-15 days from design approval. Production orders: 20-25 days depending on complexity and quantities. Express service available: 8-10 days for prototypes. Lead times include both fabrication and small batch assembly if required. These timelines are faster than industry average of 18-30 days.

Q4: What materials do you use for rigid flex PCB manufacturing?

We work with comprehensive material options: Rigid sections use FR4, high-Tg, Rogers, or other specialized laminates. Flexible sections use polyimide films (adhesive or adhesiveless). Coverlay materials: acrylic or PSA adhesive based. Stiffeners: FR4, polyimide, or stainless steel. Material selection depends on your specific application requirements including flex cycles, temperature range, and environmental exposure.