Rigid flex PCB fabrication pushes manufacturing technology limits. When a defense contractor needed rigid flex boards for missile guidance systems, they required 24-layer rigid sections with 6-layer flexible interconnects, controlled impedance throughout, and operation from -55°C to +125°C. Three suppliers declined the project. The fourth attempted manufacturing but delivered unusable boards with delamination and impedance failures.

The challenge combined extreme layer count, mixed materials, thermal requirements, and controlled impedance—each difficult individually, catastrophic together without proper fabrication capabilities. Understanding rigid flex fabrication capabilities helps you identify qualified suppliers and avoid costly failures.

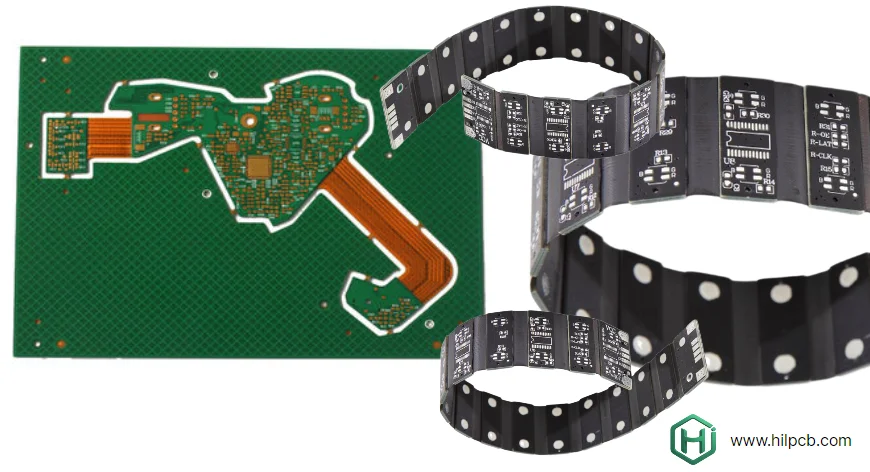

At HILPCB, we provide advanced rigid flex PCB fabrication supporting complex designs from prototype through production, combining HDI PCB technology with specialized flexible circuit expertise.

Layer Count and Complexity Capabilities

Rigid flex PCB fabrication complexity varies dramatically from simple designs to highly complex multilayer constructions. Understanding capability ranges helps match your design to appropriate manufacturers.

Standard Complexity Designs

Entry-level rigid flex fabrication handles: 2-8 layers in rigid sections, 1-2 layers in flexible sections, adhesive-based polyimide construction, and standard trace widths (100-150μm). These designs represent 70% of rigid flex applications and most PCB manufacturers claiming rigid flex capability can produce them reasonably well.

A consumer electronics product using rigid flex connecting main board to display requires 4-layer rigid with single-layer flex—well within standard capability range. Multiple suppliers can quote competitively, and fabrication proves straightforward.

Advanced Complexity Designs

High-end rigid flex fabrication supports: 8-64 layers in rigid sections, 2-6 layers in flexible sections, adhesiveless polyimide for high flex life, fine line traces (75-50μm), microvias and HDI technology, and sequential lamination for buried flex layers.

These designs require specialized equipment, advanced materials expertise, and process optimization. A medical implantable device needs 16-layer rigid with 4-layer flex, 75μm traces, and adhesiveless construction. Only a fraction of rigid flex manufacturers possess required capabilities. We maintain equipment and expertise for these demanding applications.

Layer Transitions and Stackup Options

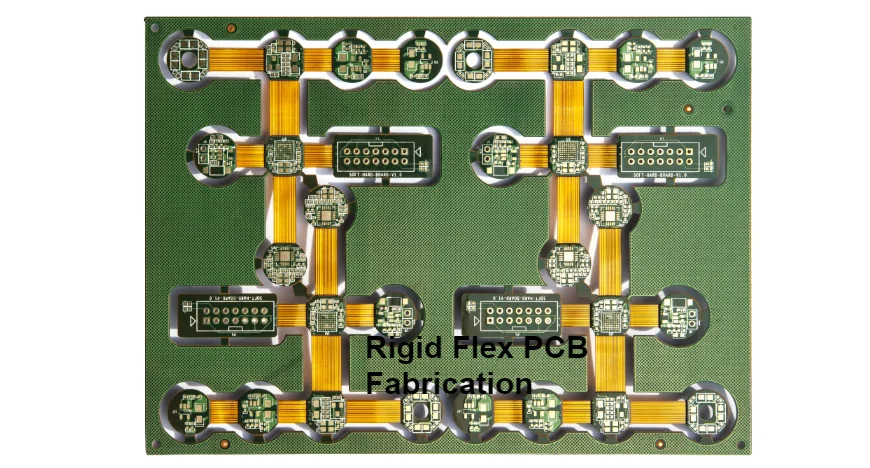

Rigid flex fabrication enables various stackup architectures:

- Surface flex: Flexible circuits on outer layers of rigid-flex stackup

- Internal flex: Flexible circuits buried within rigid stackup requiring sequential lamination

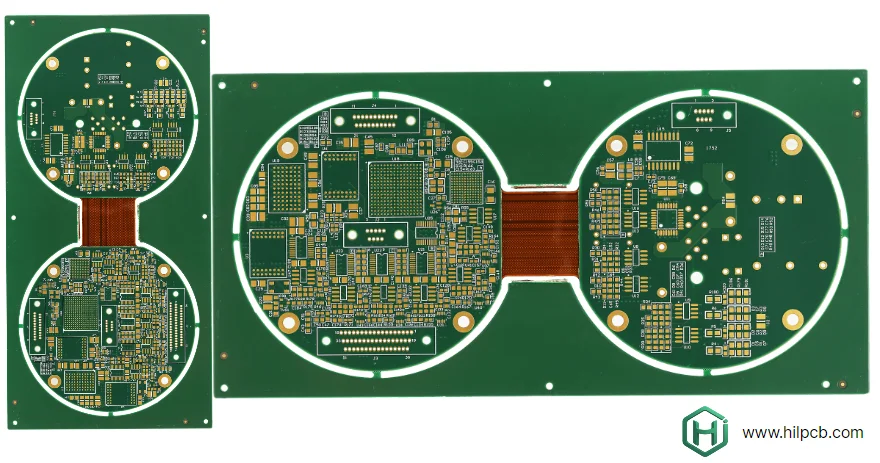

- Asymmetric construction: Different layer counts in different rigid sections

- Multiple flex layers: Independent flexible circuits at different stackup depths

A satellite communications system uses asymmetric construction with 12-layer main rigid section, 8-layer processor rigid section, and 2-layer flex interconnecting sections. This optimizes cost and weight while meeting electrical requirements of each subsystem.

Via Technology and Interconnection Methods

Via structures in rigid flex boards present unique fabrication challenges. The vias must transition between rigid and flexible sections, handle different material properties, and maintain reliability through flexing.

Through-Hole Vias

Traditional through-hole vias drill completely through board stackup connecting all layers. In rigid flex construction, through vias passing through flexible sections reduce flex life significantly. The copper-plated via barrel creates a stiff point resisting flexing—generating stress concentration during bending.

Minimize through vias in flexible sections when possible. When unavoidable, increase via diameter and use filled vias distributing stress more evenly. An automotive sensor design initially specified 0.3mm vias throughout. Our DFM review recommended 0.5mm vias in flexible sections—larger via handles stress better. Testing confirmed 3x flex life improvement from larger vias.

Blind and Buried Vias

Blind vias connect outer layer to internal layers without penetrating entire stackup. Buried vias connect internal layers without reaching outer surfaces. Both via types enable higher routing density and minimize via penetration through flexible sections.

Multilayer PCB fabrication using blind/buried vias requires sequential drilling and lamination—first laminating inner layers, drilling and plating buried vias, then adding outer layers with blind vias. This sequential process increases fabrication complexity and cost but enables designs otherwise impossible.

Microvias for HDI

Microvias (100-150μm diameter) created by laser drilling enable ultra-high density interconnection. The small via size and aspect ratio (depth-to-diameter) limitations mean microvias typically connect just 2-3 layers maximum. Multiple microvia layers stack creating complex 3D interconnection networks.

We fabricate rigid flex incorporating microvia HDI technology: laser drilling 100μm microvias, via-in-pad capability for maximum density, stacked and staggered microvia options, and microvia filling for reliability. A smartphone design uses 10-layer rigid section with stacked microvias achieving routing density impossible with traditional vias, all while maintaining flexible interconnect to display assembly.

Controlled Impedance Fabrication

High-speed signals require controlled impedance throughout transmission path. Fabricating controlled impedance in rigid flex proves more challenging than standard rigid boards due to material property variations and transition zone effects.

Impedance Modeling Challenges

Standard impedance calculators assume uniform material properties throughout trace length. Rigid flex boards have: varying dielectric constants (FR4 vs polyimide), different coverlay effects vs solder mask, material thickness variations, and impedance discontinuities at transitions.

We use electromagnetic field solvers modeling complete rigid flex stackup: accounting for all material property variations, simulating transition zone impedance changes, and optimizing trace geometry for target impedance. A high-speed PCB design required 100Ω differential impedance through rigid-flex transition. Standard calculators showed meeting spec impossible—EM simulation revealed trace width adjustment in transition zone maintaining impedance within ±5%.

Test Coupon Design

Impedance test coupons must represent actual board construction including material variations and transitions. Standard rigid PCB coupons don't validate rigid flex impedance.

Our test coupon design includes: traces through rigid sections, traces through flexible sections, traces through rigid-flex transitions, and differential pairs where used. Time-domain reflectometry (TDR) testing verifies impedance meets specifications before boards ship.

High-Frequency Considerations

RF and microwave applications operating above 1 GHz require specialized materials beyond standard FR4 and polyimide. Rogers PCB materials provide stable dielectric properties and low loss at high frequencies.

We fabricate rigid flex using Rogers high-frequency laminates in rigid sections combined with low-loss polyimide in flexible sections. Material interfaces require careful design preventing impedance discontinuities. A 5G antenna assembly operates at 28 GHz using Rogers RO4003C rigid sections with Kapton polyimide flex sections—maintaining impedance and minimizing loss throughout signal path.

Material Processing Expertise

Different materials require different processing parameters. Rigid flex fabrication combines multiple materials each with unique processing requirements.

Polyimide Processing

Polyimide requires different processing than FR4: higher lamination temperatures (280-350°C vs 170-200°C for FR4), longer lamination cycles, different etching chemistry, and moisture sensitivity requiring pre-baking.

Our polyimide processing expertise includes: climate-controlled material storage, vacuum baking procedures removing moisture, specialized etching processes, and lamination profiles optimized for polyimide properties. This expertise prevents common polyimide processing defects including delamination, copper adhesion failures, and dimensional instability.

Adhesive System Selection

Bonding rigid and flexible sections requires adhesive systems compatible with both materials. The adhesive must: flow properly at lamination temperature, provide strong bonds to both FR4 and polyimide, withstand operating temperature ranges, and maintain properties through multiple thermal cycles.

We work with multiple adhesive systems selecting optimal type for each application. A medical device operating from 0°C to +85°C uses different adhesive than automotive application running -40°C to +125°C. Adhesive selection affects both fabrication process and long-term reliability.

Coverlay Application

Coverlay lamination protects flexible circuits. Unlike solder mask applied by screen printing, coverlay requires precision lamination: correct temperature and pressure profiles, registration alignment between coverlay and circuits, and edge finishing preventing coverlay lifting.

Our coverlay lamination uses dedicated equipment with: controlled heating zones, programmable pressure profiles, precision registration systems (±50μm), and automated defect inspection. Quality coverlay application protects flexible circuits throughout product life.

Tolerances and Manufacturing Precision

Rigid flex PCB fabrication requires tighter tolerances than standard rigid boards. The multiple materials and processes create opportunities for dimensional variations affecting quality and reliability.

Dimensional Tolerances

We maintain tight dimensional control: ±75μm registration between layers, ±50μm hole position tolerance, ±25μm trace width tolerance, and ±10% thickness tolerance. These tolerances ensure: controlled impedance accuracy, reliable via connections, consistent electrical performance, and proper mechanical fit.

A connector mating design requires ±100μm position tolerance—our ±50μm capability provides margin ensuring all boards meet requirements. Compare to standard PCB tolerances of ±150-200μm showing precision requirements for rigid flex.

Material Thickness Control

Total thickness and layer-to-layer thickness variations affect electrical performance and mechanical flexibility. We control: rigid section thickness ±10%, flexible section thickness ±8%, and overall assembly thickness ±12%.

A wearable device design has 1.0mm maximum thickness constraint fitting into enclosure. Thickness tolerance means actual thickness ranges 0.88-1.12mm. We manufactured at 0.95mm nominal providing margin ensuring all boards fit within enclosure while maintaining required electrical and mechanical properties.

Edge Quality

Flexible circuit edges require special attention during routing (cutting). Standard PCB routing leaves rough edges potentially delaminating during handling or flexing. We use: precision routing tools specifically for polyimide, controlled routing speeds preventing tearing, and edge finishing treatments improving durability.

Preview your design files using our PCB viewer tool before submission for quote, though complete design review requires quote request page submission for engineering analysis.

Quality Standards and Certifications

Rigid flex PCB fabrication for regulated industries requires documented quality systems and comprehensive testing.

Industry Standards Compliance

We maintain compliance with: IPC-6013 (rigid flex requirements), IPC-A-600 (PCB acceptability), IPC-4101 (material specifications), and application-specific standards (medical, aerospace, automotive).

These standards define: material requirements, manufacturing processes, inspection criteria, and testing protocols. Compliance ensures consistent quality and provides documentation for regulated industries.

First Article Inspection

New designs undergo first article inspection (FAI) verifying: dimensional accuracy, material conformance, electrical performance, impedance verification, and mechanical properties. FAI documentation provides baseline for production monitoring and enables design qualification.

Traceability and Documentation

Complete material and process traceability tracks: material lot numbers, processing equipment, operator identification, test results, and environmental conditions. This traceability enables root cause analysis when issues occur and provides documentation for regulatory compliance.

FAQ - Rigid Flex PCB Fabrication

What's the most critical step in rigid flex PCB fabrication?

Final lamination bonding rigid and flexible sections. This step requires specialized equipment, precise process control, and expertise. Poor lamination causes majority of rigid flex failures. Verify manufacturer has dedicated rigid-flex lamination presses, not just standard PCB equipment.

Why does rigid flex PCB fabrication take longer than standard PCBs?

Two parallel processes (rigid and flex) must be completed before critical lamination step. Additional time needed for:

- Flex section processing (different than rigid)

- Precise alignment during lamination

- Extended lamination cycles

- Additional inspection requirements Total adds 5-7 days vs standard multilayer PCB of equivalent complexity.

How can I verify manufacturer's rigid flex PCB fabrication capability?

Request:

- Cross-section photos from recent production

- Process flow diagram showing all steps

- Equipment list with lamination press details

- Sample inspection reports

- References from similar projects Quality manufacturers readily provide this information.

What causes most rigid flex fabrication failures?

Top failure modes:

- Delamination (poor lamination process)

- Copper cracking at transitions (design or process)

- Registration errors (alignment during lamination)

- Via failures (drilling or plating issues) All preventable with proper equipment and processes.

Should I request cross-section analysis with my order?

For production orders: Yes, request sample cross-sections

- Verifies lamination quality

- Confirms stack-up construction

- Documents via quality

- Provides quality assurance Small additional cost ($50-100) provides significant confidence. We include cross-section analysis with all production orders of rigid-flex PCB at no extra charge.