Scaling from prototype to production volumes reveals whether your rigid flex PCB supplier truly understands manufacturing. A wearable device startup successfully validated 10 prototypes—then ordered 1,000 production units discovering their supplier couldn't deliver. The factory handled low-volume orders but lacked capacity, process control, and quality systems for production.

After 8-week delay and $40,000 in expediting fees, they found a production-capable supplier. The experience taught an expensive lesson: prototype capability doesn't guarantee production capability. Success requires planning production transition from day one, not after prototype validation.

At HILPCB, we support rigid flex PCB production from initial prototypes through millions of units, providing scalable manufacturing with large volume assembly capabilities and comprehensive quality systems.

Production Transition Planning

The journey from prototype to production requires strategic planning beginning with initial design. Companies treating prototype and production as separate projects encounter unnecessary delays, costs, and quality issues.

Design for Manufacturing from Start

DFM (Design for Manufacturability) considerations affect both prototype viability and production scalability. Design choices impacting production include: material availability in production quantities, process complexity affecting yield rates, tooling requirements for volume manufacturing, and test/inspection procedures for production.

A medical device manufacturer designed rigid flex using specialized polyimide material with excellent properties but limited availability. Prototypes succeeded but production orders faced 12-week material lead times. Switching to readily-available alternative material required redesign and requalification—6-month delay. Considering material availability during design phase would have prevented this issue.

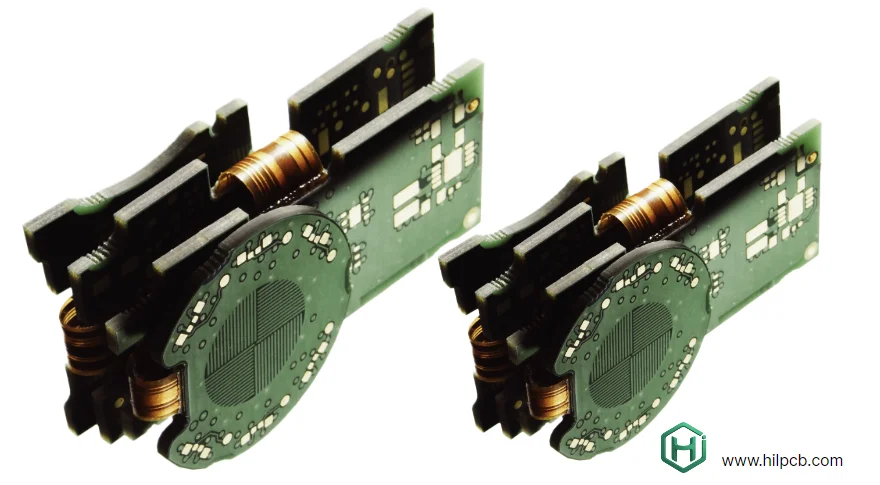

Prototype Process Consistency

Manufacturers using different processes for prototypes vs production create risk. If prototype process differs from production, performance might not translate to production boards. We use identical processes and materials for prototypes and production ensuring validated prototypes reliably predict production performance.

Early Production Planning

Production planning should begin during prototype phase: identifying volume requirements and timeline, understanding component availability at volume, planning tooling and fixture requirements, and establishing quality requirements and testing protocols. This planning enables smooth production transition when prototype validation completes.

Volume Pricing Structure and Cost Optimization

Rigid flex PCB production costs decrease significantly with volume. Understanding pricing structure helps plan product pricing and profit margins.

Typical Volume Break Points

Pricing structure follows general pattern:

- Prototypes (5-10 units): $80-300 per design depending on complexity. High setup cost amortized over few units.

- Pilot Production (50-200 units): $25-80 per board. Setup costs spread across more units, material volume discounts begin.

- Low Volume (500-2,000 units): $12-40 per board. Dedicated production runs, optimized processes, better material pricing.

- Production (5,000-50,000 units): $6-20 per board. Full volume discounts, minimal setup cost per board, optimized yield.

- High Volume (100,000+ units): $3-12 per board. Maximum efficiency, continuous production runs, best material pricing.

These ranges represent typical 4-6 layer rigid flex designs. Complexity, materials, and features adjust pricing accordingly. An IoT sensor design priced at $45 for 10 prototypes, $18 at 500 units, $9 at 5,000 units, and $5.50 at 100,000 units—88% cost reduction from prototype to high volume.

Cost Optimization Strategies

Multiple approaches reduce rigid flex PCB production costs:

Material Optimization: Substitute expensive specialty materials with cost-effective alternatives where performance allows. A consumer electronics product initially specified adhesiveless polyimide ($30/sq ft) throughout. Engineering review identified that only 30% of flex area experienced dynamic flexing requiring adhesiveless—remaining 70% could use adhesive-based polyimide ($12/sq ft) saving $4.20 per board at 50,000 units/year = $210,000 annual savings.

Layer Count Reduction: Evaluate if design requires all specified layers. A 6-layer rigid flex design with low routing density can often become 4-layer reducing cost 25-35%. Our engineering team reviews designs identifying optimization opportunities without compromising functionality.

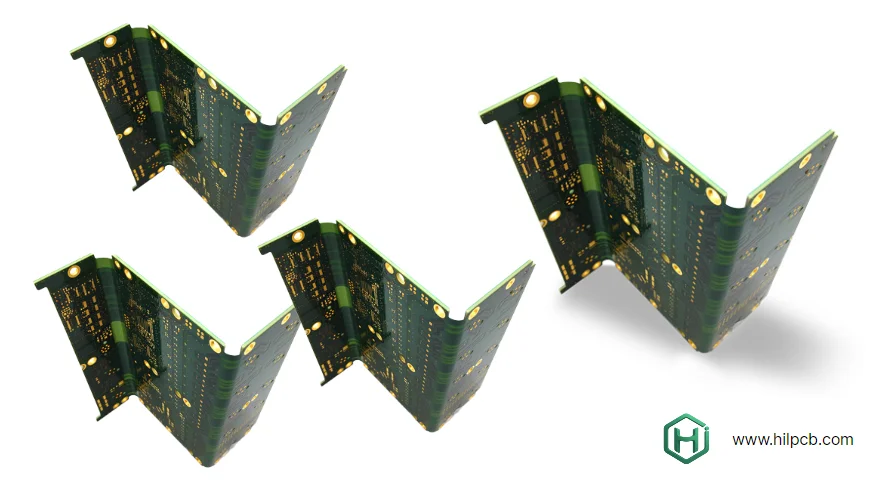

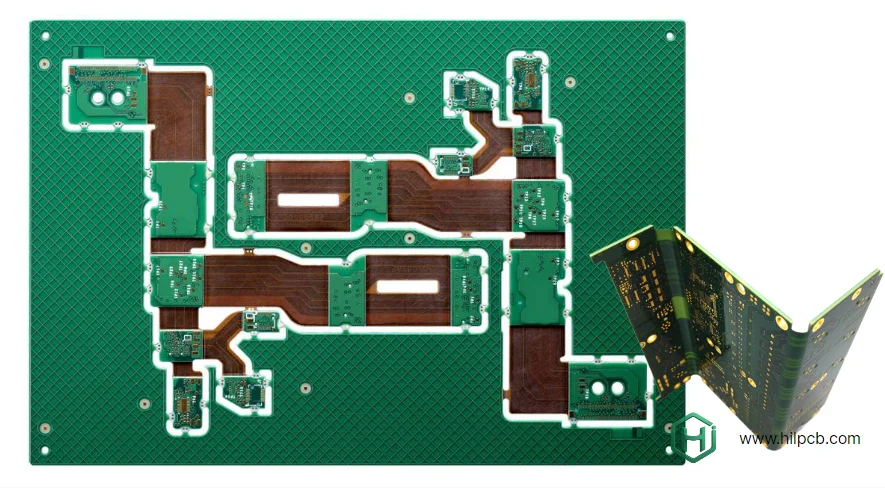

Panelization Efficiency: How many boards fit per production panel affects unit cost. Optimizing board dimensions for panel utilization reduces waste and lowers cost. Standard panel sizes: 12" x 18" (common) or 18" x 24" (larger volumes). Board design enabling more units per panel reduces cost proportionally.

Assembly Optimization: Component selection affects assembly cost. Using common components vs specialized parts reduces procurement cost and lead time. Turnkey assembly services benefit from volume component purchasing—we source components at better pricing than customers achieve individually.

Production Capacity and Scheduling

Understanding supplier production capacity prevents surprises during volume ramps. Questions to ask potential production partners:

Monthly Production Capacity

What monthly volume can supplier support? Many rigid flex manufacturers quote impressive capabilities but run 2-3 month backlogs. A consumer electronics launch required 20,000 boards monthly for 3 months. Their supplier claimed capacity but couldn't deliver—other customer orders filled production slots. Launch delayed 10 weeks.

We maintain adequate capacity supporting volume commitments: dedicated production lines for rigid flex, priority scheduling for committed volumes, and capacity planning preventing overcommitment.

Ramp Planning

Production rarely starts at full volume. Typical volume ramp: pilot production (50-200 units) validating process, initial production (500-2,000 units) establishing supply chain, volume ramp (5,000-20,000 units) approaching target volume, and steady state (target monthly volume) ongoing production.

Supporting volume ramp requires: flexible scheduling accommodating changing volumes, maintaining quality as volumes increase, and identifying and resolving issues before full volume.

Lead Time Management

Production lead times vary with volume: small batch assembly (50-200 units): 18-22 days, low volume (500-2,000 units): 22-28 days, and production volumes (5,000+ units): 25-30 days. Express service available reducing lead times 30-40% with premium pricing.

Component availability often drives lead times more than board fabrication. Long lead time components (specialized ICs, connectors) require early ordering. We provide component lead time analysis during quoting identifying potential bottlenecks.

Quality Management for Production

Production quality management requires systematic processes preventing defects rather than just catching them. Statistical process control, root cause analysis, and continuous improvement distinguish professional production operations.

Process Control and Monitoring

Production monitoring tracks key parameters: material thickness variations, copper plating uniformity, lamination temperatures and pressures, via hole quality metrics, and electrical test results. Trending this data identifies process drift before defects occur.

An automotive electronics manufacturer experienced increasing electrical failures—0.5% initially but increasing to 2% over 2 months. Root cause analysis traced issue to copper plating bath contamination causing reduced plating thickness. Process monitoring would have detected contamination earlier before significant scrap accumulated.

Incoming Material Inspection

Production quality starts with material quality. We inspect all incoming materials: laminates tested for thickness, dielectric constant, polyimide films checked for defects, wrinkles, contamination, and adhesives verified for proper storage conditions, aging. Material defects causing production failures cost far more than inspection—preventing bad material from entering production saves money.

First Article Inspection

Each new production run undergoes first article inspection comparing: dimensional measurements vs specifications, electrical parameters vs requirements, cross-sectional analysis of via and layer structures, and mechanical testing where applicable. FAI confirms process produces compliant boards before full production continues.

Ongoing Production Inspection

Automated optical inspection (AOI), electrical testing, and sampling inspection occur throughout production. For multilayer PCB production, we inspect: after etching each layer, after lamination, after drilling and plating, and during final inspection. Multi-stage inspection catches defects early reducing scrap cost.

Supply Chain Management

Rigid flex PCB production involves complex supply chains: board materials, components, assembly materials, and packaging. Effective supply chain management prevents delays and cost overruns.

Material Supply Planning

Production material requirements exceed prototype quantities—sometimes by 100-1,000x. Suppliers maintaining inventory for prototypes may not stock production volumes. Long lead time materials require advance planning: specialty polyimide films (8-12 weeks), high-frequency laminates (6-8 weeks), and specialized finishes (4-6 weeks).

We maintain inventory of common rigid flex materials supporting immediate production starts: standard polyimide types, common laminate materials, and various adhesive systems. For specialized materials, we provide lead time warnings during quoting enabling early ordering.

Component Management

Component availability drives production schedules. Critical steps: identifying long lead time components early, designing with available components vs allocated/obsolete parts, maintaining component inventory for production, and developing alternate sources for critical components.

We provide component sourcing analysis with production quotes using our BOM viewer tool for initial analysis, though complete BOM review requires quote request page submission. This analysis identifies: components with >8 week lead times, obsolete or end-of-life parts, single-source components presenting risk, and expensive components where alternatives exist.

Buffer Inventory Strategy

Managing production schedules requires buffer inventory: work-in-process inventory absorbing production variations, finished goods inventory supporting customer demand variability, and safety stock protecting against supply disruptions. Buffer size depends on demand variability, lead times, and supply reliability.

Why Choose HILPCB for Rigid Flex PCB Production?

When it comes to rigid flex PCB manufacturing, choosing the right partner can make all the difference in ensuring high-quality, efficient production. At HILPCB, we specialize in providing seamless production from prototype to high-volume manufacturing, offering advanced capabilities to meet your unique design and performance needs.

Key advantages of choosing HILPCB for your Rigid Flex PCB production include:

- Seamless Transition from Prototype to High Volume: We ensure that your prototype design seamlessly transitions into high-volume production, minimizing delays and costly revisions. Our process guarantees that the performance and reliability of prototypes are replicated in large-scale manufacturing.

- Cost Optimization: We provide cost-effective solutions through material optimization, layer count reduction, and panelization efficiency. This results in significant savings as your production volume increases, making your product more competitive in the market.

- Advanced Quality Control Systems: HILPCB implements rigorous quality control throughout the production process. From material inspection to first article inspections and ongoing production checks, we ensure that every board meets strict standards, reducing defects and ensuring long-term reliability.

- Automated Production and Continuous Improvement: With our advanced automated systems, we continuously improve production efficiency and consistency. This not only helps reduce labor costs but also increases capacity without compromising quality.

- Supply Chain Reliability: HILPCB maintains strong relationships with suppliers and has a robust inventory management system. We proactively manage material availability, ensuring that production schedules are not impacted by supply chain delays.

- Flexible Production Capacity: Whether you're starting with small-batch prototypes or scaling to large-volume orders, HILPCB can accommodate your needs with dedicated production lines and flexible scheduling, ensuring timely delivery and quality assurance at every stage.

By partnering with HILPCB, you gain a reliable, experienced manufacturer who understands the complexities of rigid flex PCBs. Our expertise ensures that your product is produced efficiently, on time, and with the highest quality standards.

Get your production quote today and let us help you bring your PCB projects to life with precision and reliability.