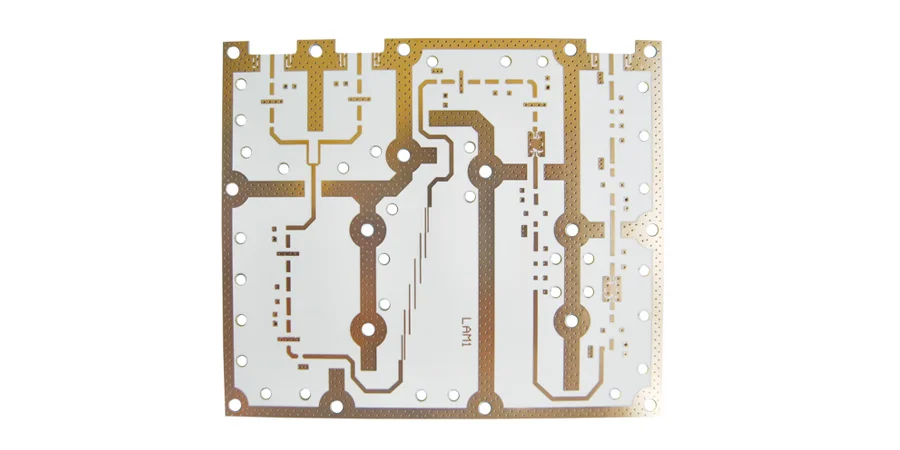

Rogers 4350B is a high-frequency laminate material that is widely used in high-performance PCBs due to its excellent electrical properties and thermal stability. At Highleap PCB Factory, we specialize in manufacturing and assembling Rogers 4350B PCBs, offering advanced solutions for industries that require exceptional signal integrity, high-speed data transmission, and durability in extreme conditions.

Rogers 4350B offers superior performance in high-frequency applications, with low Dk (dielectric constant) and Df (dissipation factor), making it perfect for microwave systems, satellite communication, and other high-speed designs. The material's ability to handle high-power and high-frequency signals with minimal loss ensures reliable performance in even the most demanding environments.

The Advantages of Rogers 4350B Material

Rogers 4350B offers several advantages that make it an ideal choice for high-frequency PCB manufacturing. These advantages include:

- Low Loss and High Stability: The low loss characteristics of Rogers 4350B make it a top choice for high-speed data transmission, ensuring that signals remain stable and interference is minimized.

- Thermal Stability: Rogers 4350B material can withstand high temperatures, which is essential for applications in harsh environments such as aerospace and automotive electronics.

- Excellent Mechanical Properties: This material is strong and durable, providing the structural integrity required for multilayer PCBs and high-density interconnect (HDI) PCBs.

- High-Frequency Performance: Rogers 4350B is optimized for high-frequency circuits, ensuring minimal signal loss and high-speed data transmission for applications such as 5G infrastructure, microwave circuits, and telecommunication systems.

At Highleap PCB Factory, we offer Rogers 4350B PCBs that are carefully engineered to meet the specific requirements of each project, ensuring that your designs are reliable and perform at their best.

Applications of Rogers 4350B PCBs

The exceptional properties of Rogers 4350B make it ideal for a wide range of high-performance applications, including:

- Telecommunications: Rogers 4350B PCBs are used in base stations, RF modules, and communication systems, where high-speed signal transmission is essential.

- Aerospace: Rogers 4350B is used in satellite communication systems, radar applications, and aerospace sensors, where durability and thermal stability are crucial.

- Medical Devices: Rogers 4350B is found in high-performance medical electronics such as ECG monitors, MRI systems, and diagnostic equipment, where signal integrity and reliability are paramount.

- Microwave Systems: The low-loss properties of Rogers 4350B make it ideal for microwave systems, ensuring efficient signal transmission over long distances.

Highleap PCB Factory offers customized Rogers 4350B PCB solutions that are tailored to your specific application needs, ensuring superior performance and reliability in every design.

Specialized Materials for Rogers PCBs

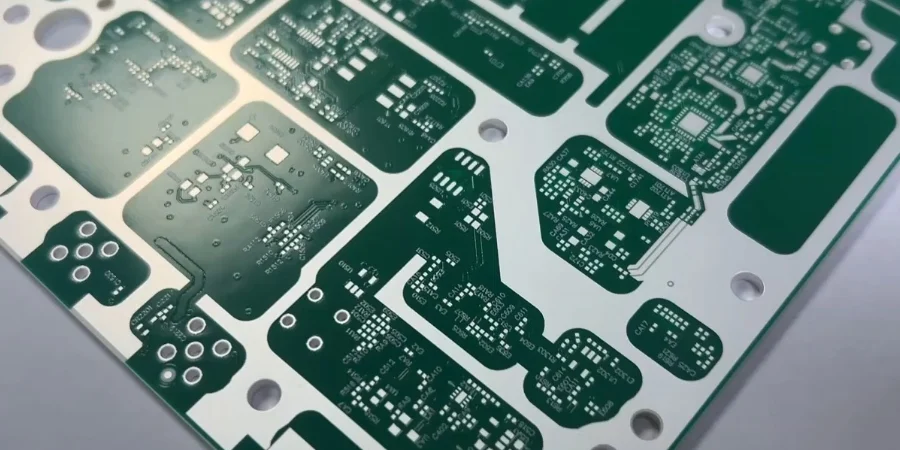

In high-frequency and RF applications, material choice can significantly influence signal integrity, thermal performance, and long-term reliability. Rogers PCBs are favored in such demanding designs because they use engineered substrates that outperform standard FR-4 in every key parameter that matters at GHz-level frequencies.

Two of the most widely used high-performance materials in this category are the RO4000 and RO3000 series:

- RO4000 Series Laminates: These materials strike a balance between electrical performance and cost-effectiveness. With a stable dielectric constant across a wide frequency range and low dissipation factor, the RO4000 series is ideal for systems requiring consistent impedance and thermal reliability. Common applications include base stations, automotive radar, RF modules, and aerospace electronics.

- RO3000 Series Laminates: Designed for extremely high-frequency designs, the RO3000 series exhibits ultra-low dielectric loss, low outgassing, and minimal temperature-dependent variation. It’s a preferred choice for millimeter-wave radar, satellite payloads, and point-to-point microwave links where signal loss and phase stability are critical.

Beyond performance characteristics, these materials also offer excellent processability during PCB fabrication. Their mechanical stability ensures compatibility with standard PCB manufacturing processes, while their thermal durability allows for complex multilayer stackups with minimal warpage.

At Highleap PCB Factory, we support a wide selection of Rogers PCB materials, tailored to meet your electrical and mechanical design requirements. Whether you're developing compact 5G antennas, RF front-end modules, or mixed-signal systems, our expertise with RO3000 and RO4000 laminates ensures that your PCBs perform reliably under the toughest environmental and signal integrity demands.

Design Considerations for Rogers PCBs

When designing Rogers PCBs, several critical factors must be considered to ensure that the board performs optimally:

- Signal Integrity: Maintaining signal integrity is critical in high-speed and high-frequency designs. Rogers PCBs offer low Dk and Df, ensuring minimal signal loss, which is crucial for communication systems, 5G networks, and other applications.

- Thermal Management: Managing heat dissipation is vital in high-frequency circuits. The use of Rogers PCB materials ensures that heat can be managed effectively, allowing the device to operate at optimal temperatures without performance degradation.

- Impedance Control: Impedance control is necessary for high-frequency PCBs to prevent reflections and signal distortion. Rogers PCBs allow for accurate impedance control, ensuring reliable and stable signal transmission in critical applications.

At Highleap PCB Factory, we use state-of-the-art tools such as Impedance Calculator and Gerber Viewer to validate your Rogers PCB designs before manufacturing, ensuring that all the critical factors are optimized.

Why Choose Highleap PCB Factory for Your Rogers PCB Needs?

When you're working with high-frequency designs, you can’t afford compromises. That’s why engineers and product teams worldwide turn to Highleap PCB Factory for reliable, high-performance Rogers PCB manufacturing.

We go beyond standard fabrication—we partner with you from concept to completion, ensuring every PCB we produce is tailored for maximum signal integrity, thermal reliability, and performance at microwave and RF levels.

Here’s what sets us apart:

- Specialized High-Frequency Expertise With years of hands-on experience in RF, microwave, and millimeter-wave PCB manufacturing, we understand the challenges of Rogers material processing, controlled impedance routing, and minimizing insertion loss.

- Material Versatility and Inventory We stock and work with a wide range of Rogers materials—including RO4350B, RO4003C, RO3003, and more—so your project isn't delayed by sourcing or substitutions.

- Fast Prototyping with Precision From quick-turn prototypes to production-scale volumes, we deliver consistent quality with tight tolerances and minimal lead times, allowing you to move fast without sacrificing quality.

- One-on-One Engineering Support Our engineers collaborate closely with your team on stackup planning, DFM optimization, and layout guidelines to ensure your final product meets all technical and application-specific demands.

At Highleap, we know your RF circuits are mission-critical—whether it's for 5G antennas, radar systems, satellite links, or medical imaging devices. That’s why we don’t just manufacture—we help you engineer success.

Contact us today to get a custom Rogers PCB quote, and discover how Highleap can elevate your next high-frequency project.