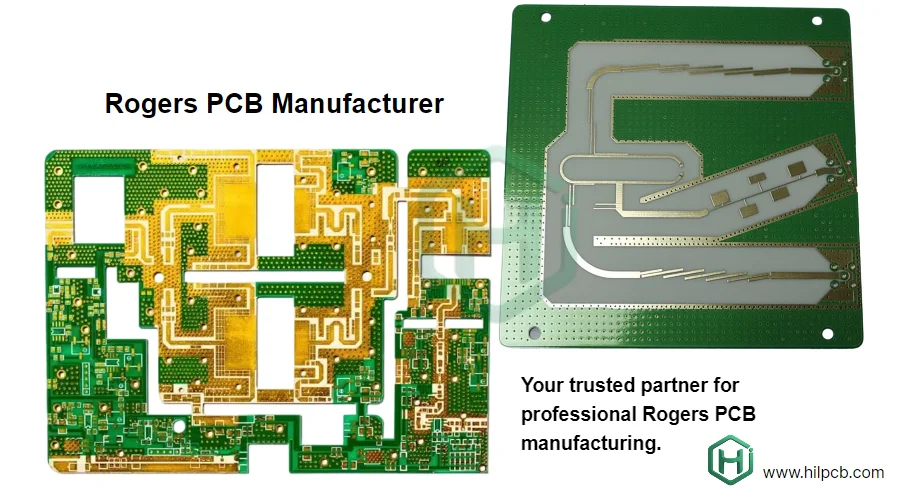

HILPCB Factory is a global leader in Rogers PCB manufacturing, providing precision-engineered, high-frequency circuit boards for the world’s most demanding electronic systems. We process all major Rogers materials — including 4003C, 4350B, 5880, 6002, and TMM series — to deliver exceptional performance for telecommunications, radar, aerospace, automotive, and defense applications.

Our engineering expertise, advanced fabrication technology, and rigorous quality systems ensure every Rogers PCB meets the strictest standards for signal integrity, reliability, and long-term stability.

Comprehensive Expertise in Rogers PCB Manufacturing

With over 20 years of experience, HILPCB has mastered the full range of high-frequency PCB manufacturing processes, from PTFE composites to ceramic-filled substrates. Our engineers understand the unique challenges of Rogers materials — such as adhesion, drilling precision, and thermal control — enabling consistent yields and stable RF characteristics.

End-to-End Engineering Capabilities

- Stackup optimization: Material and dielectric tuning to achieve controlled impedance.

- Thermal and signal analysis: Simulation ensures stability under high power and temperature variations.

- RF modeling: Advanced field-solver analysis predicts performance before fabrication.

- Manufacturing scalability: From single prototype to mass production, we adapt to every stage of your product lifecycle.

These capabilities ensure reliable performance in applications ranging from high-speed PCB modules to advanced IC substrate PCB designs.

Rogers Material Portfolio: 4003C, 4350B, 5880, 6002, and TMM

RO4003C

A hydrocarbon ceramic laminate with Dk = 3.38, RO4003C balances electrical performance with easy manufacturability. Compatible with standard FR4 PCB processes, it reduces cost while maintaining consistency up to 10 GHz — ideal for 5G base stations, automotive radar, and antenna arrays.

RO4350B

Glass-reinforced hydrocarbon ceramic offering superior mechanical stability and low Z-axis expansion, reducing via fatigue during thermal cycling. Commonly used in multilayer RF, backplane PCB, and high-reliability communication hardware.

RT/duroid 5880

An ultra-low-loss PTFE composite (Dk = 2.20, tanδ = 0.0009) providing exceptional phase stability and minimal signal attenuation. The preferred choice for aerospace radar, satellite communication, and precision navigation systems.

Rogers 6002

Ceramic-filled PTFE laminate with 3× the thermal conductivity of standard PTFE, ideal for high-power amplifiers, inverters, and heavy copper PCB circuits.

TMM Series

Thermoset microwave materials combining ceramic reinforcement with polymer stability. With dielectric constants from 3.27 to 12.85, they provide dimensional stability, low moisture absorption, and compatibility with lead-free assembly — making them suitable for halogen-free PCB applications.

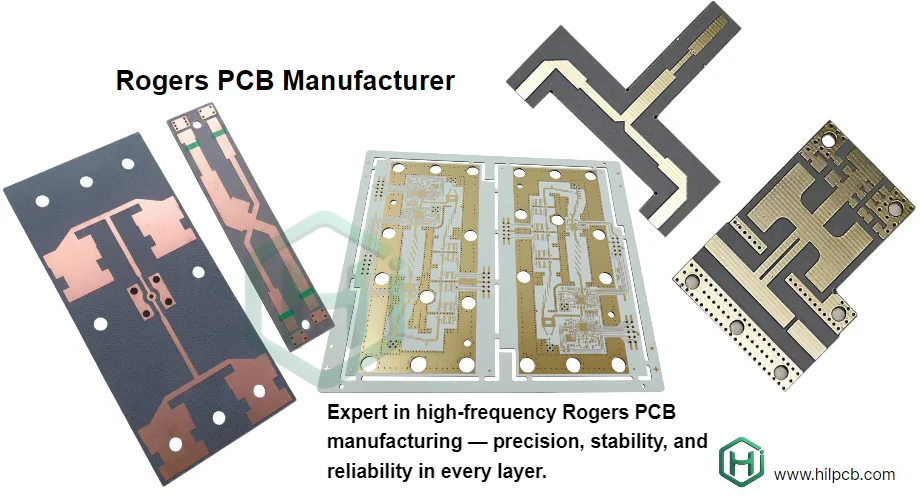

Advanced Fabrication Techniques for High-Frequency Precision

Unlike standard FR4, Rogers laminates require dedicated processing sequences to maintain dielectric consistency, copper adhesion, and mechanical stability. At HILPCB, each Rogers production line operates under controlled environmental and process parameters specifically tuned for PTFE-based and ceramic-filled materials.

Key Manufacturing Processes

- Surface Preparation and Copper Adhesion: Rogers materials such as RO4003C or TMM series have low surface energy, making adhesion challenging. We employ plasma activation and oxide-alternative treatments to roughen and chemically modify copper surfaces, ensuring robust bond strength without degrading dielectric uniformity.

- Lamination Control: Precise temperature and pressure profiles are critical. Our vacuum-assisted lamination eliminates voids between layers and ensures uniform resin flow. For hybrid constructions combining FR4 PCB and Rogers cores, we synchronize Tg and flow characteristics to prevent delamination or resin starvation.

- Drilling and Via Metallization: PTFE and ceramic-filled laminates demand low mechanical stress and high precision. We use diamond-coated tools for mechanical drilling and UV/CO₂ laser systems for microvias. Following drilling, plasma desmear and chemical cleaning remove fluoropolymer residues before copper deposition—essential for stable plated-through holes in HDI PCB designs.

- Imaging and Etching: Fine-line patterning uses laser direct imaging (LDI) for ±10 µm accuracy. We adjust exposure energy for high-reflective copper surfaces typical of low-loss foils. Optimized etching chemistry minimizes undercutting to achieve consistent trace width and impedance control in multilayer PCB structures.

- Copper Plating and Surface Finishing: Controlled electroplating ensures uniform copper thickness in high-aspect-ratio vias (up to 10:1). For RF and microwave assemblies, we offer ENIG, ENEPIG, and immersion silver finishes that maintain low insertion loss while supporting SMT assembly.

- Environmental Stability: Every fabrication zone maintains <45% relative humidity and ±1°C temperature control to preserve dimensional stability. Continuous monitoring prevents moisture uptake that could shift dielectric properties or cause warpage.

Consistent Accuracy Across Frequencies

By combining precise lamination control, refined drilling parameters, and low-stress plating processes, HILPCB achieves trace/space as small as 60 µm and maintains dielectric uniformity across large panels. This ensures consistent impedance performance from DC to 40 GHz—meeting the requirements of radar systems, high-speed digital backplanes, and 5G communication modules.

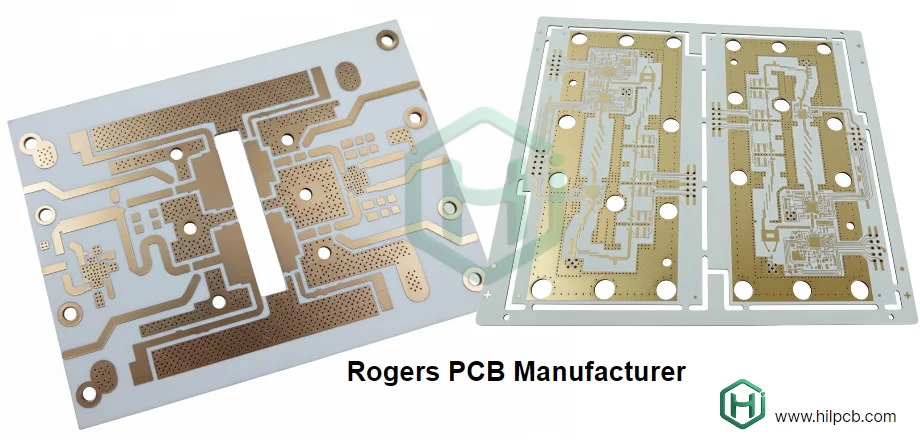

Impedance Control and Quality Verification

Signal accuracy begins with precise impedance control — the cornerstone of professional Rogers PCB manufacturing.

Engineering and Validation

- Pre-production modeling using 3D field solvers to verify design tolerances.

- In-process dielectric and plating thickness measurements ensure consistency.

- Final testing via time-domain reflectometry (TDR) for ±5% impedance accuracy.

Process Monitoring and Documentation

Every batch is tracked through Statistical Process Control (SPC), with control charts monitoring variation and capability indexes validating stability. Each delivery includes a full documentation pack: test results, cross-section photos, and certification data for flexible PCB and rigid-flex assemblies.

This approach guarantees repeatable impedance performance — essential for turnkey assembly and RF integration.

Certifications, Environmental Responsibility, and Security

HILPCB Factory adheres to international manufacturing standards and sustainability practices.

- Quality Certifications: ISO 9001, IPC-A-600 Class 3, IATF 16949, and AS9100 for aerospace-grade reliability.

- Environmental Compliance: RoHS, REACH, and ISO 14001 certification.

- Responsible Manufacturing: Conflict-free material sourcing and energy-efficient production lines.

- Data Protection: Secure ITAR-compliant infrastructure and confidentiality protocols for defense and metal-core PCB applications.

These certifications provide full assurance for mission-critical, high-frequency, and environmentally regulated projects.

Why Global Clients Choose HILPCB as Their Rogers PCB Partner

Technical Superiority

HILPCB’s advantage lies in our vertical integration and deep material expertise.

From stack-up design and lamination to surface finishing and assembly, every process is performed in-house — delivering unmatched consistency, shorter lead times, and superior electrical performance.

Service and Scalability

- Rapid prototyping: 24–48 hour quick-turn production for design validation.

- Flexible production volumes: From prototypes to mass manufacturing with cost-efficient scaling.

- Collaborative engineering: Real-time consultation for layout, impedance, and assembly optimization.

- Responsive communication: Project tracking with instant technical feedback.

Proven Reliability and Value

Global OEMs choose HILPCB for:

- Competitive pricing without compromising precision.

- Long-term reliability in harsh environments.

- Consistent quality verified through advanced testing.

- Engineering partnership focused on innovation, not just production.

Partner with HILPCB – Your Trusted Rogers PCB Manufacturer

At HILPCB, excellence is engineered into every layer of your PCB. Our goal is not only to manufacture, but to empower innovation — transforming high-frequency designs into reliable, production-ready solutions.

We combine engineering consultation, precision fabrication, and complete assembly services to streamline your development cycle and ensure first-pass success. Whether you’re developing next-generation radar systems, 5G infrastructure, or satellite communication modules, HILPCB provides the reliability, consistency, and support your projects demand.

Partner Benefits:

- End-to-end manufacturing: from material selection to final SMT assembly and testing.

- Dedicated project management and global logistics for on-time delivery.

- Technical documentation, test validation, and full traceability for every batch.

- Continuous process improvement ensuring superior ROI and product longevity.

With proven expertise across Rogers, TMM, and hybrid dielectric systems, HILPCB is your long-term partner for precision-engineered, high-frequency PCBs — built for today’s challenges and tomorrow’s innovation.