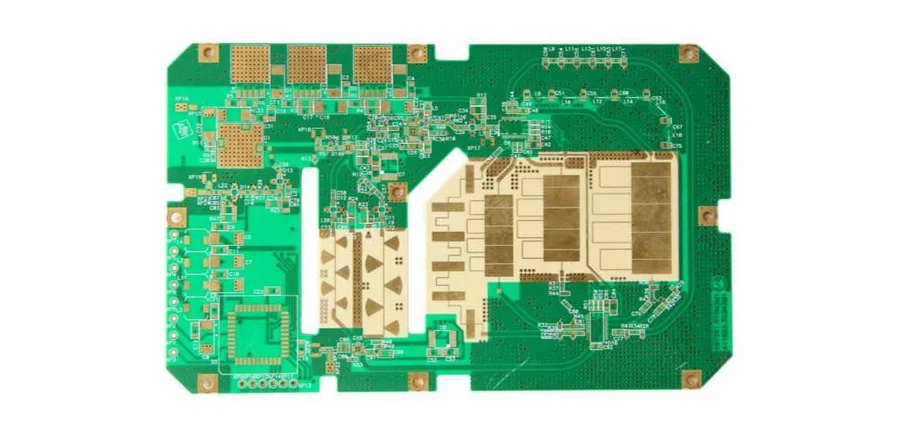

Rogers PCB materials are among the most advanced substrates in the PCB industry, specifically designed for high-frequency and high-performance applications. At Highleap PCB Factory, we specialize in manufacturing and assembling Rogers PCBs, offering advanced solutions for industries that require exceptional signal integrity, high-speed data transmission, and durability in extreme conditions.

Rogers PCB is known for its excellent electrical performance, especially in high-speed circuits, and its ability to handle high-frequency signals without causing significant signal loss. We use Rogers laminate materials in applications ranging from telecommunications to aerospace and medical devices. With Highleap PCB Factory, you can be assured of high-quality manufacturing, custom designs, and fast delivery tailored to your specific needs.

What Makes Rogers PCB Different from Other Materials?

Rogers PCB materials, such as the RO4000 Series Laminates, offer significant advantages over traditional FR4 materials in high-frequency applications. The primary difference lies in their dielectric constant (Dk) and loss tangent (Df), which significantly reduce signal loss, crosstalk, and interference. These properties are crucial for ensuring optimal signal integrity in high-speed and high-frequency applications.

Key benefits of Rogers PCB materials include:

- Superior Electrical Performance: Rogers PCBs provide low-loss performance, which is vital for high-speed, high-frequency applications like 5G communication, microwave systems, and satellite communications.

- Thermal Stability: Rogers PCB laminates offer excellent thermal stability, ensuring that the PCB can withstand temperature fluctuations without degradation of performance.

- High Durability: Rogers materials are designed to perform reliably even in harsh environments, making them suitable for military, aerospace, and industrial applications.

At Highleap PCB Factory, we utilize Rogers PCBs in advanced designs where performance and precision are critical. Our team specializes in working with complex materials, ensuring that each Rogers PCB is engineered to meet the specific requirements of the project.

Applications of Rogers PCBs

The high-performance characteristics of Rogers PCBs make them ideal for a range of demanding applications:

- Telecommunications: Rogers PCB is widely used in 5G infrastructure, microwave circuits, and RF communication systems that require stable, low-loss signal transmission.

- Aerospace: The extreme environments in aerospace require Rogers PCBs that can handle high frequencies and maintain signal integrity, even under stress and high temperatures.

- Medical Devices: Rogers PCBs are used in medical electronics like ECG monitors, MRI systems, and diagnostic equipment where reliability and precise signal transmission are paramount.

- Automotive: In automotive electronics, Rogers PCBs are used in systems like radar, sensors, and infotainment that require high-performance and reliable signal handling.

These applications require specialized PCB designs, and Highleap PCB Factory is at the forefront of providing custom Rogers PCBs that meet the exacting demands of these industries.

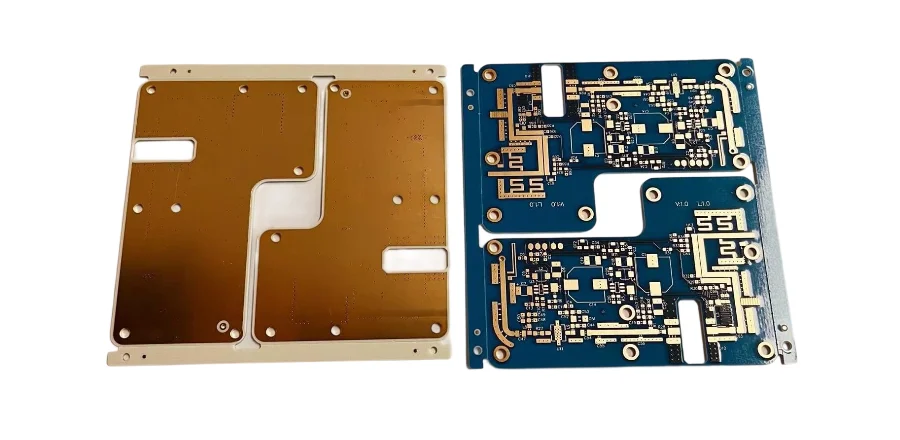

Specialized Materials for Rogers PCBs

For applications that require the highest performance, Rogers PCBs are made using advanced materials like RO3000 and RO4000 series laminates. These materials offer high-frequency stability, low-loss properties, and the ability to handle extreme temperatures. Some of the most common materials used in Rogers PCBs include:

- RO4000 Series Laminates: Known for their excellent electrical performance and thermal stability, RO4000 series laminates are used in applications such as telecommunications, satellite communications, and automotive radar systems.

- RO3000 Series: These materials are designed for high-frequency, high-speed applications, providing low signal loss, minimal crosstalk, and low-cost performance for more affordable designs without compromising on quality.

At Highleap PCB Factory, we provide custom Rogers PCB solutions that use these high-performance materials, ensuring that your designs will deliver the best possible performance in demanding environments.

Design Considerations for Rogers PCBs

When designing Rogers PCBs, several critical factors must be considered to ensure that the board performs optimally:

- Signal Integrity: Maintaining signal integrity is critical in high-speed and high-frequency designs. Rogers PCBs offer low Dk and Df, ensuring minimal signal loss, which is crucial for communication systems, 5G networks, and other applications.

- Thermal Management: Managing heat dissipation is vital in high-frequency circuits. The use of Rogers PCB materials ensures that heat can be managed effectively, allowing the device to operate at optimal temperatures without performance degradation.

- Impedance Control: Impedance control is necessary for high-frequency PCBs to prevent reflections and signal distortion. Rogers PCBs allow for accurate impedance control, ensuring reliable and stable signal transmission in critical applications.

At Highleap PCB Factory, we use state-of-the-art tools such as Impedance Calculator and Gerber Viewer to validate your Rogers PCB designs before manufacturing, ensuring that all the critical factors are optimized.

Why Choose Highleap PCB Factory for Your Rogers PCB Needs?

At Highleap PCB Factory, we offer more than just Rogers PCBs. Our focus is on providing custom solutions for complex PCB designs, ensuring that we meet the specific needs of your high-performance applications.

We offer:

- Advanced Design Expertise: We have extensive experience designing Rogers PCBs for high-frequency and high-speed applications.

- High-Performance Materials: We use Rogers materials, as well as other advanced substrates, to ensure the best performance in demanding environments.

- Rapid Prototyping and Production: We provide quick turnaround times for prototyping and flexible production options for both small batches and large-scale manufacturing.

- Global Support: Our team provides comprehensive support, from design consultation to delivery, ensuring that your project is completed successfully.

Whether you're looking for Rogers PCBs for telecommunications, medical devices, or aerospace applications, we have the expertise to deliver the high-performance PCBs you need.