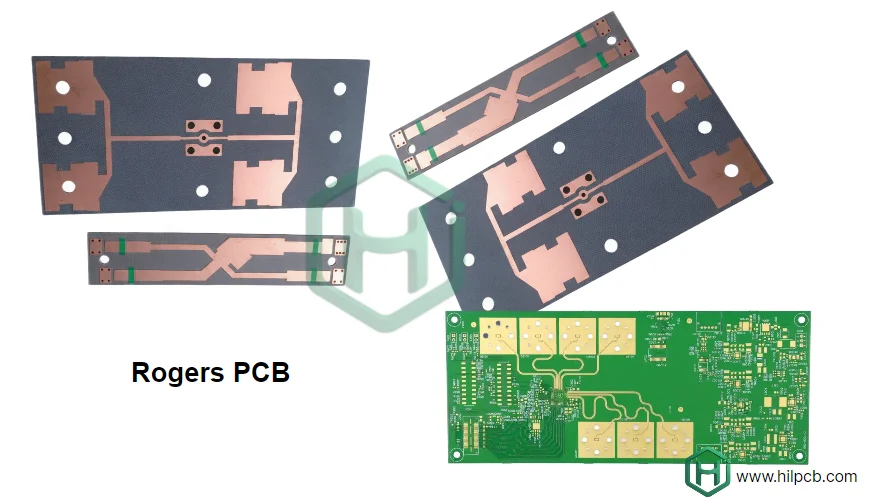

At HILPCB, we provide full-cycle Rogers PCB production services — from prototype development to high-volume manufacturing — ensuring uniform performance and reliability across every build. Our expertise in RF, microwave, and high-speed PCB manufacturing supports demanding industries such as telecommunications, aerospace, automotive, and defense, where precision and consistency define success.

Optimized Rogers PCB Production Workflow

Every project begins with a comprehensive DFM and signal integrity review, verifying manufacturability and impedance consistency. Early engineering validation minimizes risks during fabrication and ensures material stackups perform as designed.

Material planning integrates directly with production scheduling. We maintain certified Rogers stock — including RO4003C, RO4350B, RT/duroid 5880, and RO6002 — to support urgent RF builds and planned releases. Traceable batch management and lot control provide full documentation, meeting stringent aerospace and medical standards.

Dedicated prototype lines handle small-run builds within 24–72 hours, while automated production cells and high-throughput panelization support cost-efficient volume manufacturing. Real-time tracking across all stages ensures transparency, allowing customers to monitor project status seamlessly.

From Certified Materials to Final Testing

Our production reliability begins with authentic Rogers materials sourced directly from verified suppliers. Each batch undergoes thickness, Dk/Df verification, and copper foil surface inspection before entering fabrication. Moisture-controlled storage and clean-room lamination maintain material stability — critical for high-frequency PCB consistency.

PTFE-based laminates such as RT/duroid require unique processing conditions — plasma activation for adhesion and precision drilling to prevent resin smear. Ceramic-filled laminates like RO4350B need specialized routing tools minimizing edge chipping, while TMM substrates achieve tighter tolerances through thermoset stability.

Comprehensive inspection guarantees repeatable quality:

- AOI (Automated Optical Inspection) for trace accuracy

- Flying-probe and impedance testing for electrical verification

- Cross-section analysis ensuring proper lamination and plating

- Full documentation: CoC, test data, and RoHS/REACH compliance

Advanced Manufacturing and Equipment Capabilities

Our production facilities integrate state-of-the-art equipment for precision and scalability:

- Laser Direct Imaging (LDI): ±25 μm registration for fine-line RF geometries

- CO₂ and UV laser drilling: Microvias down to 75 μm for HDI PCB structures

- Vacuum-assisted lamination: Ensures void-free bonding for multilayer Rogers stackups

- Automated surface treatment and plasma cleaning: Enhances copper adhesion and surface energy control

- Controlled-depth routing: Enables cavities and antenna recesses for rigid-flex PCB applications

Surface finishes include ENIG, ENEPIG, immersion silver, and selective hard gold, supporting both SMT and RF connector reliability.

Consistency and Process Control in Volume Production

Scaling from prototype to mass production requires process uniformity and data-driven control. Our SPC systems continuously monitor plating, etching, and drilling precision, identifying variations before they affect output. Each process stage operates under controlled parameters, maintaining impedance tolerance within ±5%.

Standardized workflows and operator training ensure identical results across shifts and production batches. Lot-level serialization enables traceability from lamination to test, vital for defense and aerospace compliance. For customers requiring large volume assembly or phased delivery, we provide flexible scheduling, buffer stock programs, and just-in-time logistics.

Industries and End Applications

HILPCB’s Rogers PCB production supports diverse, performance-critical markets:

- Telecommunications: 5G base stations, RF front-end modules, MIMO antenna arrays

- Aerospace & Defense: Radar, navigation, and communication subsystems

- Automotive Electronics: ADAS radar, V2X modules, EV power systems

- Industrial & Medical: Sensors, microwave imaging, and control systems

Our high-frequency manufacturing combines tight impedance control, thermal reliability, and mechanical stability, ensuring consistent RF behavior even under harsh environmental conditions.

Partner with HILPCB for Reliable Rogers PCB Production

Choosing HILPCB means more than manufacturing — it’s a partnership for long-term product reliability and scalability. Our engineering team collaborates from prototype through mass production, applying design-for-manufacturing (DFM) and cost optimization strategies that reduce lead times and enhance yield.

We offer:

- Flexible order models: prototypes, pilot runs, or volume batches

- Blanket orders and Kanban programs: stabilize pricing and availability

- Quick-turn options: 24–48 h expedited builds

- Continuous improvement programs: leveraging customer feedback for ongoing optimization

With ISO 9001, IATF 16949, and AS9100 certifications, HILPCB delivers Rogers PCB production that meets the highest international standards for performance, reliability, and traceability.