At HILPCB Factory, we specialize in quick-turn Rogers PCB prototyping and high-frequency PCB manufacturing designed for fast and accurate RF validation. Our 24–48 hour delivery capability empowers engineers to iterate quickly while maintaining the precision demanded by advanced RF, microwave, and millimeter-wave applications.

We serve global innovators developing products for wireless communications, automotive radar, satellite payloads, and aerospace navigation — where signal integrity and turnaround time are equally critical.

Why Rapid Prototyping Is Critical in RF Design

In RF and microwave design, even minor variations in material or geometry can significantly affect impedance, signal loss, and system stability. Simulations alone cannot account for all parasitic and tolerance effects — making physical Rogers PCB prototypes indispensable for real-world validation.

Benefits of Fast Rogers Prototyping

- Immediate performance feedback: Detect mismatches and resonance issues before committing to production tooling.

- Accelerated product cycles: Enable faster iteration in antenna tuning and circuit optimization.

- Lower overall cost: Identify layout or material issues early, preventing expensive rework later in large-volume assembly.

- Improved reliability: Validate materials and stackups for temperature, humidity, and vibration resilience.

By bridging simulation and production through quick-turn prototyping, RF teams can validate design assumptions under real electrical, thermal, and mechanical conditions.

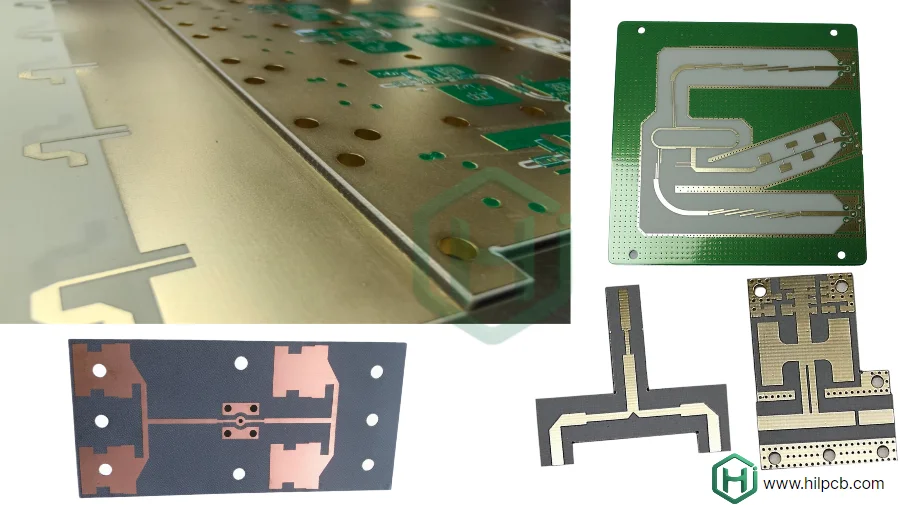

HILPCB's Advanced Capabilities in High-Frequency PCB Manufacturing

HILPCB integrates advanced fabrication technology and precision process control to meet the stringent demands of high-frequency PCB manufacturing. Our production systems are engineered for the unique challenges of Rogers materials — from micro-geometry control to dielectric consistency.

Key Engineering Capabilities

- Laser Direct Imaging (LDI): Ensures sub-75 µm trace accuracy and tight impedance control.

- Laser Microvia Drilling: Enables stacked and staggered vias in HDI PCB designs.

- Sequential Lamination: Supports hybrid Rogers + FR4 PCB constructions.

- Controlled Copper Plating: Maintains uniform deposition for stable signal transmission.

- Environmental Process Control: Constant humidity and temperature ensure dimensional stability for thin dielectric cores.

- Back-Drilling & Copper Balancing: Minimize stub resonance and phase delay for precision RF routing.

We routinely achieve aspect ratios up to 10:1 and maintain impedance tolerances within ±5%, critical for high-speed PCB and RF module designs.

Rogers Material Selection for High-Frequency PCB Prototyping

At HILPCB, we maintain a broad and certified inventory of Rogers high-frequency laminates, covering the full spectrum from hydrocarbon-ceramic to PTFE and thermoset composites. Selecting the right material directly determines RF stability, impedance control, and thermal reliability — essential for successful microwave and millimeter-wave prototyping.

RO4000 Series — Cost-Effective and Reliable

- RO4003C / RO4350B / RO4835

Hydrocarbon-ceramic materials with Dk 3.38–3.66 and low loss (0.0027–0.0037).

Excellent for 5G modules, radar sensors, and mixed-signal circuits.

RO4835 adds oxidation resistance for higher temperature stability.

Compatible with FR4 PCB processes, ideal for hybrid stackups.

RT/duroid Series — Ultra-Low Loss for Aerospace and Defense

- RT/duroid 5870 / 5880 / 6002 / 6010LM

PTFE-based materials with Dk from 2.2 to 10.2 and extremely low loss (as low as 0.0009).

Designed for satellite communication, radar, and phased-array antennas.

Excellent phase stability and low moisture absorption.

Preferred in high-frequency PCB and precision radar systems.

RO3000 Series — Balanced Electrical and Mechanical Properties

- RO3003 / RO3010 / RO3035 / RO3203

Ceramic-filled PTFE composites with Dk 3.0–10.2, stable over temperature and humidity.

Used in base station filters, power amplifiers, and GPS modules.

Offers tight dielectric tolerance for repeatable impedance control.

RO6000 Series — High Thermal Conductivity for Power RF

- RO6002 / RO6035HTC / RO6202 / RO6633N

Enhanced thermal conductivity (0.8–1.2 W/m·K) and low Z-axis expansion.

Ideal for power amplifiers, microwave converters, and automotive radar.

Compatible with metal-core PCB thermal designs.

TMM Thermoset Series — Ceramic Stability with Easier Processing

- TMM3 / TMM6 / TMM10i / TMM13

Thermoset microwave laminates with Dk 3.27–13 and loss tangent below 0.002.

High copper adhesion, no cold flow, and CTE matched to copper.

Used in aerospace filters, oscillators, and high-stability RF modules.

Advanced Material Integration

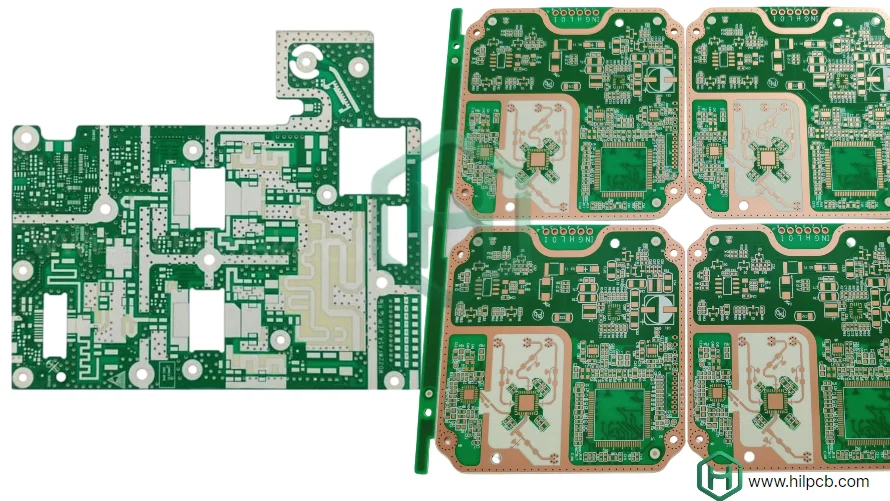

HILPCB supports hybrid stackups combining Rogers and FR4 layers, such as RO4350B + FR4 or TMM + RO4003C, achieving a balance of electrical performance, cost, and mechanical strength. Our engineers assist with stackup design, impedance modeling, and dielectric selection to ensure consistent high-frequency behavior across prototypes and production.

From Prototype to Production: Seamless Transition

Transitioning from prototype to production is a critical phase. At HILPCB, we ensure smooth scaling through:

- DFM Optimization: Design refinement for manufacturability and yield improvement.

- Process Matching: Consistency between prototype and full-scale production settings.

- Material Continuity: Verified sourcing of identical Rogers laminates for volume production.

- Integrated SMT Assembly: In-house assembly and turnkey manufacturing minimize logistics complexity.

- Documentation Control: Full traceability with Gerber, impedance, and test reports for production continuity.

This integration shortens lead times and preserves electrical performance from prototype validation to mass deployment.

Partner with HILPCB for Rogers PCB Prototyping and Manufacturing

At HILPCB, we combine speed, precision, and technical depth to help RF engineers achieve first-pass success. Our quick-turn Rogers PCB prototyping and high-frequency PCB manufacturing services deliver end-to-end support — from design review to assembled and tested prototypes ready for integration.

Why Choose HILPCB

- 24–48 hour turnaround for standard configurations.

- Advanced equipment and experienced RF engineers.

- Certified processes (ISO 9001, IATF 16949, AS9100).

- Global delivery and responsive customer support.

When time-to-market and performance precision matter most, HILPCB provides the agility, expertise, and reliability your RF program requires.