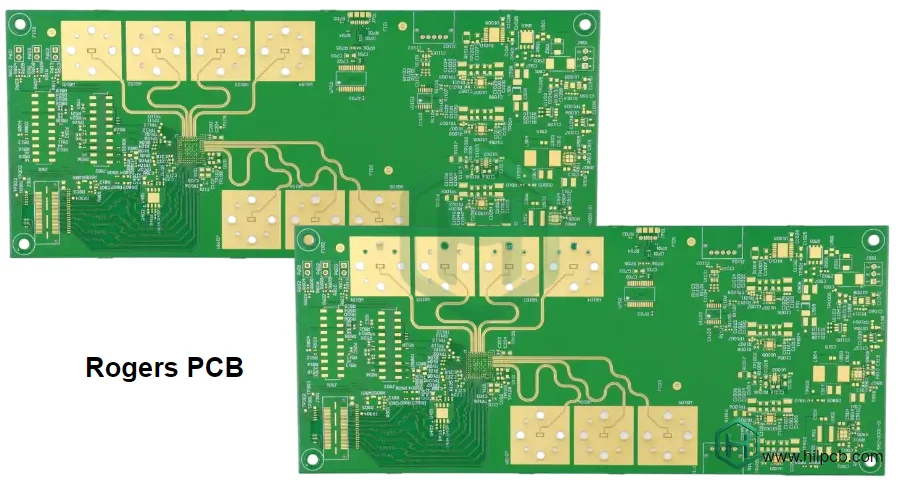

HILPCB is a globally trusted Rogers PCB supplier, offering verified material sourcing and precision manufacturing for RF, microwave, and millimeter-wave designs. With strong material partnerships, certified quality systems, and an efficient global logistics network, we ensure engineers and OEMs receive authentic Rogers laminates—on time, every time.

What to Look for in a Professional Rogers PCB Supplier

Choosing the right Rogers PCB supplier involves more than stock availability—it requires material traceability, technical expertise, and process control.

Authenticity and Certification

HILPCB sources all laminates directly from authorized Rogers distributors, supplying full Certificates of Conformance, lot traceability, and dielectric verification data. Counterfeit prevention ensures reliability for high-value single-double layer PCB designs.Technical Expertise and Material Matching

Our engineers understand the nuances of RO3000, RO4000, RT/duroid, and TMM series, offering precise recommendations based on frequency range, thermal needs, and dielectric constants. This enables optimal design for multilayer PCB structures and hybrid RF stackups.Integrated Fabrication and Assembly

Unlike distributors, we combine material supply with full in-house manufacturing—including high-frequency PCB fabrication, testing, and turnkey assembly. This vertical integration guarantees end-to-end quality control and simplified procurement.

HILPCB's Rogers Material Inventory and Sourcing Capabilities

We maintain one of the broadest Rogers laminate inventories in Asia, enabling rapid support for urgent RF, microwave, and mmWave builds. Materials are stocked by dielectric thickness (≈0.2–1.5 mm) and copper cladding (½–2 oz; LoPro available), with roll/ panel lots tracked for full traceability—ready for rigid-flex PCB hybrids and complex multilayer constructions.

RO3000™ Series (ceramic-filled PTFE, low loss)

- RO3003 (Dk ≈ 3.0): Low-loss baseline for L/S/C-band RF, GNSS, and filter networks.

- RO3006 (Dk ≈ 6.15): Size-reduction of resonators/filters at higher Dk with stable phase.

- RO3010 (Dk ≈ 10.2): Compact, high-Q elements for X/Ku-band, phased-arrays.

- RO3035 / RO3046 (Dk ≈ 3.5 / 4.6): Balanced footprint vs. loss for broadband radios.

RO4000® Series (hydrocarbon/ceramic, FR-4-friendly processing)

- RO4003C (Dk ≈ 3.38): Workhorse for antenna feed, RF backplanes, mixed-signal.

- RO4350B (Dk ≈ 3.48): Better CAF/mechanical stability for dense multilayers.

- RO4835 (Dk ≈ 3.48): Improved oxidation/thermal robustness for high-temp service.

- RO4360G2 (Dk ≈ 6.15): Higher Dk to shrink line lengths/filters without PTFE handling.

- RO4730JXR / RO4725JXR: Antenna-grade with tuned Dk for 4G/5G radiating elements.

- LP (LoPro) copper variants: Reduced conductor loss / better surface finish for high-speed edges.

RT/duroid® Series (PTFE composites for ultra-low loss & high Dk options)

- RT/duroid 5880 / 5880LZ (Dk ≈ 2.20): Ultra-low loss for radar, SATCOM, mmWave links.

- RT/duroid 5870 (Dk ≈ 2.33): Similar to 5880 with slightly higher Dk for matching options.

- RT/duroid 6002 (Dk ≈ 2.94): Lower Dk with good thermal balance for PA modules.

- RT/duroid 6006 / 6010LM (Dk ≈ 6.15 / 10.2): High-Dk miniaturization for filters/couplers.

RO6000® High-Thermal / Power RF (ceramic-filled PTFE)

- RO6002 (≈ Dk 2.94): Baseline for power RF, converters, and broadband RF power.

- RO6035HTC / RO3006-class HTC: Elevated thermal conductivity for PA heat flow while retaining low loss.

TMM™ Thermoset Microwave Materials (thermoset + ceramic)

- TMM3 / TMM4 / TMM6 / TMM10 / TMM10i (Dk ≈ 3.3–~10): Thermoset processability (no cold-flow), tight CTE match, stable Dk for multilayer RF and mixed-signal stacks.

Copper options: ED, LoPro, RA (for flex/low-roughness). Cladding and dielectric options are aligned to common impedance targets (50/75 Ω single-ended; 85/100/112 Ω differential) to shorten stackup tuning cycles.

Custom procurement: For specialty grades (e.g., RO3003G2, antenna-tuned RO47xx, uncommon thicknesses, LoPro RA foils, ultra-thin cores), we aggregate demand to hit MOQs quickly and keep lead-times predictable. All lots ship with CoC, lot/date codes, and dielectric data for incoming IQC.

Custom Material Procurement

When standard stock does not fit unique requirements, HILPCB provides:

- Non-standard laminate thicknesses or prepreg variants

- Rolled-annealed copper foils for high-frequency signal integrity

- Hybrid stackups combining Rogers with FR-4 for cost optimization

We consolidate multi-customer orders to achieve efficient MOQs and ensure consistent supply while maintaining traceable origin for every lot.

Supply Chain Efficiency and Delivery Control

HILPCB’s advanced supply chain platform ensures zero-delay sourcing and seamless delivery.

Streamlined Operations

- Real-Time Inventory Visibility: Monitors material flow and production schedules

- Automated MRP Systems: Prevents shortages and forecast gaps

- Integrated Documentation: Simplifies customs and compliance reporting

- Global Logistics Partnerships: Enable fast and reliable transport worldwide

Flexible Delivery Programs

Our supply models adapt to your production scale:

- Blanket orders with scheduled release

- Kanban-based replenishment

- Vendor-managed inventory (VMI) systems

- 24–48 hour express dispatch for time-sensitive builds

These models ensure continuous production for large volume assembly while reducing procurement overhead.

Industries That Depend on Reliable Rogers PCB Supply

Telecommunications and 5G Networks

Base stations, small cells, and high-speed backhaul systems depend on stable dielectric properties and tight material tolerances. Rogers substrates like RO4350B and RT/duroid 5880 enable low-loss transmission in backplane PCB and antenna module manufacturing.

Aerospace and Defense

Rogers materials provide unmatched reliability under thermal cycling and vibration. HILPCB’s traceable supply and lot-controlled storage ensure compliance for radar, avionics, and satellite systems operating across extreme environments.

Automotive Electronics

Electric and autonomous vehicles integrate Rogers substrates into ADAS sensors, radar modules, and V2X units. Our IATF 16949-qualified supply chain ensures consistent quality for high-Tg PCB and RF control systems.

Industrial and Energy Applications

Rogers 6002 and TMM10i materials are widely used in power electronics, energy management, and industrial automation. HILPCB guarantees thermal stability and consistent Dk control for efficient high-frequency power conversion.

Partner with HILPCB – Your Global Rogers PCB Manufacturing Partner

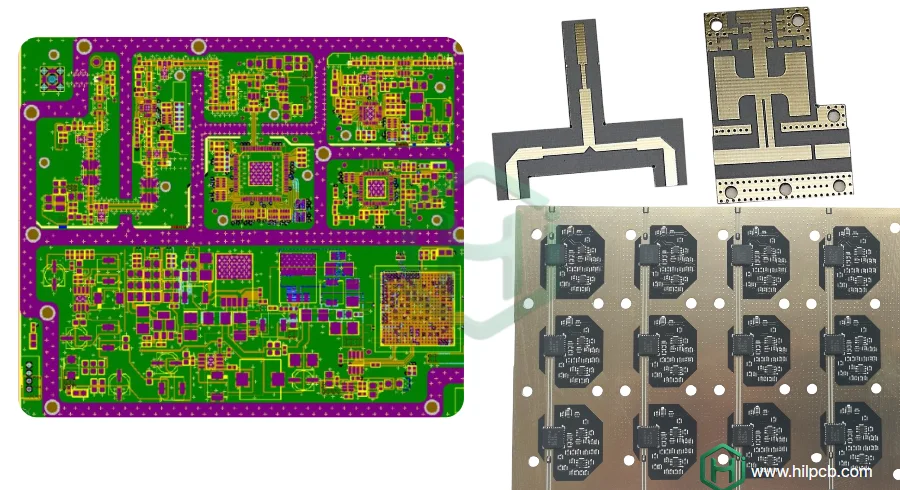

At HILPCB Factory, we don’t act as a reseller — we are a full-scale electronic manufacturer specializing in Rogers-based PCB fabrication and assembly. Our role is to transform verified Rogers laminates into high-performance PCBs for RF, microwave, and millimeter-wave systems, combining engineering precision with mass production reliability.

What Makes HILPCB Different

- Complete Manufacturing Ecosystem: In-house fabrication, SMT assembly, testing, and packaging — no outsourcing or third-party handling.

- Advanced RF Process Control: Precision impedance tuning, hybrid stack-up engineering, and controlled-depth laser drilling for multilayer RF boards.

- Certified Manufacturing System: ISO 9001, IATF 16949, and AS9100 quality frameworks ensure consistency for telecom, defense, and automotive projects.

- Flexible Capacity: From prototype runs to full large-volume assembly, our factory scales to your program requirements.

- Hybrid Material Expertise: Seamlessly integrating Rogers with FR-4 or HDI PCB structures for cost-performance optimization.

- Reliable Global Fulfillment: Dedicated logistics and export experience guarantee dependable lead times for every region.

A Complete Partner for RF Electronics

HILPCB supports your entire high-frequency product cycle — from DFM and impedance consultation to final assembly and testing. We combine signal integrity modeling, laser direct imaging, and X-ray quality inspection to ensure each Rogers PCB delivers consistent results across production lots. Our engineers collaborate closely with clients in 5G infrastructure, radar, satellite, and EV electronics, helping them achieve stable performance and faster time-to-market.

When you need a manufacturing partner who understands Rogers materials at both the engineering and production level, HILPCB delivers the precision, reliability, and global support your RF systems demand.