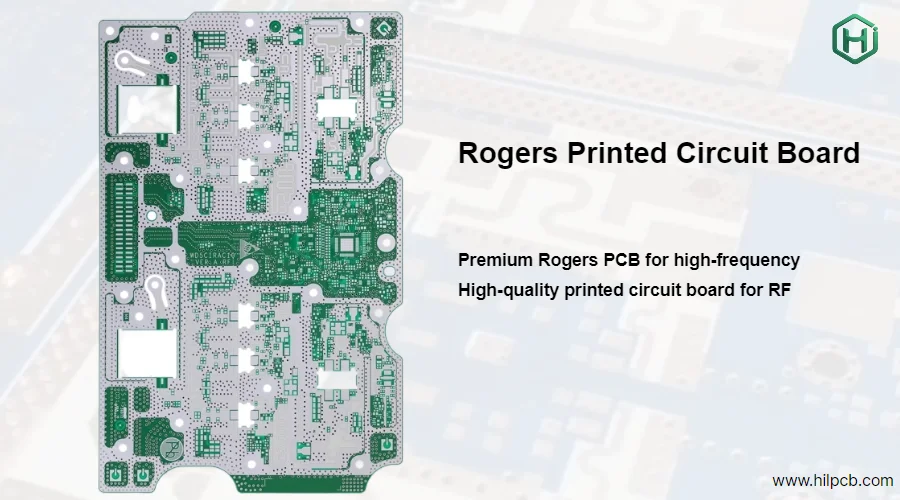

As a specialized Rogers printed circuit board manufacturer, HILPCB provides complete fabrication and assembly services for high-frequency RF and microwave applications. Our factory is equipped with advanced processing equipment specifically calibrated for Rogers laminate materials, ensuring optimal electrical performance and manufacturing reliability for your critical wireless and radar projects.

From rapid prototyping to volume production, we deliver Rogers printed circuit boards that meet the stringent requirements of telecommunications equipment, automotive sensors, aerospace systems, and industrial RF applications.

Industries Using Rogers Printed Circuit Boards

Our Rogers printed circuit board manufacturing serves customers across multiple high-tech sectors:

Wireless Communication Systems

- Cellular base station power amplifiers and filters

- WiFi 6E and WiFi 7 routers and access points

- Bluetooth and BLE modules for IoT devices

- LoRaWAN gateways and sensor networks

- Satellite communication terminals

Radar and Sensing

- Automotive radar (24GHz, 77GHz, 79GHz frequency bands)

- Weather radar and air traffic control systems

- Industrial radar level sensors and proximity detectors

- Security and surveillance radar applications

- Ground penetrating radar for construction

Test and Measurement

- RF signal generators and spectrum analyzers

- Network analyzers and vector network analyzers (VNA)

- Oscilloscopes with high-frequency front-ends

- Antenna measurement and calibration equipment

- Laboratory instrumentation up to 110GHz

Military and Aerospace

- Airborne communication and navigation systems

- Electronic warfare and countermeasure equipment

- Missile guidance and control circuits

- Unmanned vehicle (UAV/UAS) data links

- Space-qualified satellite electronics

Our high-frequency PCB manufacturing capabilities support Rogers printed circuit boards operating from UHF through millimeter-wave frequencies.

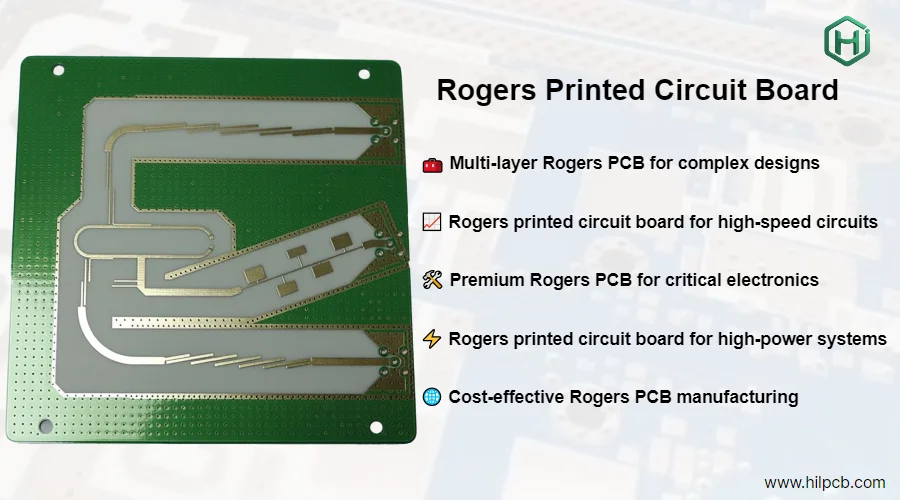

Selecting the Ideal Rogers Printed Circuit Board Materials

For high-frequency applications, choosing the right Rogers PCB material is crucial to ensuring both performance and reliability. Whether you’re designing for wireless communication, radar systems, or industrial applications, the right material can significantly impact your product's functionality and longevity.

Key elements of our Rogers PCB material selection strategy include:

- Cost-effective material options for balanced performance and cost, such as RO4003C and RO4350B

- High-performance materials like RO3003 and RO3006 for ultra-low loss and high Dk requirements

- Specialized solutions like the RO5000 Series for extreme environments (-50°C to +150°C) and RT/duroid Series for legacy applications

- Hybrid stack-up configurations combining Rogers high-frequency layers with cost-effective FR4 cores for digital and power layers

- Material optimization to balance signal integrity, thermal stability, and manufacturing costs

By applying these strategies, we ensure Rogers PCBs provide superior electrical performance, thermal stability, and design flexibility—helping customers meet the rigorous demands of their high-tech applications and achieve reliable, long-lasting products.

Complete Rogers Printed Circuit Board Assembly

PCB Assembly Capabilities

One-stop Rogers printed circuit board manufacturing and assembly:

Surface Mount Technology

- Component size: 01005 chip to 50mm x 50mm BGA packages

- Fine-pitch capability: 0.3mm pitch QFNs and BGAs

- Specialized handling: Rogers printed circuit boards require modified assembly parameters

- Inspection: Automated optical inspection (AOI), X-ray for hidden joints

Our SMT assembly teams are trained specifically for Rogers laminate handling, preventing delamination and ensuring long-term reliability.

Mixed Assembly

- Combination SMT and through-hole on Rogers printed circuit boards

- High-power component mounting (RF connectors, heat sinks)

- Specialized soldering techniques for Rogers materials

- IPC-A-610 Class 2 and Class 3 workmanship standards

Through-hole assembly services include wave soldering and selective soldering optimized for Rogers substrates.

Turnkey Manufacturing

- Complete component procurement from authorized distributors

- Bill of materials (BOM) management and obsolescence monitoring

- Inventory programs: Consigned material or turnkey supply

- Kitting and packaging per customer specifications

Turnkey assembly reduces your workload and ensures single-source accountability for Rogers printed circuit board projects.

Testing and Quality Assurance

Comprehensive testing validates Rogers printed circuit board performance:

- Electrical testing: Flying probe or fixture testing, 100% continuity and isolation

- RF testing: S-parameter measurement, insertion loss, return loss characterization

- Functional testing: Custom test fixtures for your specific Rogers printed circuit board application

- Environmental testing: Temperature cycling, thermal shock, humidity exposure

- Burn-in testing: Extended operation validation for critical applications

Rogers Printed Circuit Board Quality Standards

Our Rogers printed circuit board factory maintains multiple quality certifications:

- ISO 9001:2015: Comprehensive quality management system

- IATF 16949: Automotive industry quality (for automotive radar Rogers printed circuit boards)

- AS9100D: Aerospace and defense quality management

- ISO 13485: Medical device manufacturing standards

- IPC-6012 Class 2/3: Rigid PCB qualification and performance

- IPC-A-600 Class 2/3: PCB acceptability standards

- UL certification: Safety approvals for North American markets

- RoHS/REACH compliance: Environmental regulations compliance

Every Rogers printed circuit board shipment includes:

- Certificate of conformance

- Material certification from Rogers Corporation

- Dimensional inspection report

- Electrical test results

- Impedance test data (when applicable)

- IPC-A-600 visual inspection report

Production Volumes and Pricing

Flexible Rogers printed circuit board manufacturing for any quantity:

Prototype Services

- Quick-turn: 5-7 working days expedited service

- Low quantities: 1-50 pieces for development and testing

- Engineering support: DFM review and optimization recommendations

Small to Medium Production

- Batch sizes: 50-1000 pieces

- Optimized pricing through panelization

- Consistent quality with production tooling

- Small batch assembly with same quality standards as high volume

High Volume Manufacturing

- Production quantities: 1000+ pieces per month

- Volume discounts on materials and assembly

- Dedicated production lines for recurring Rogers printed circuit board orders

- JIT delivery and inventory management programs

- Large volume assembly with automated processes

Cost Optimization Strategies

- Hybrid stackups: Rogers layers only where required, FR4 for digital sections

- Material selection: Balancing performance requirements with material costs

- Panel utilization: Optimizing board size and array configurations

- Standard stackups: Utilizing proven Rogers printed circuit board constructions

Comprehensive Design Support and Customer Service

At HILPCB, we offer end-to-end design and engineering support to ensure your Rogers printed circuit board projects succeed from start to finish:

Design and Engineering Assistance

- Pre-production DFM: Detect potential manufacturing issues early to avoid delays

- Stackup Design: Optimize multilayer structures for both performance and cost-efficiency

- Impedance Modeling: Ensure correct trace geometries to meet impedance requirements

- Material Recommendations: Help you choose the ideal Rogers laminate for your application needs

- Cost Optimization: Apply value engineering techniques to reduce costs without compromising quality

- Seamless Prototype to Production: Ensure a smooth transition with design refinement and manufacturing feedback

Fast Turnaround and Logistics

- Quick Quotes: Receive a response within 24 hours

- Rapid Prototyping: 5-10 working days for prototype PCBs

- Standard Production: 12-18 working days for full production runs

- Rush Services: Available for urgent projects

Global Shipping and Support

- Global Delivery: Express shipping via DHL, FedEx, and UPS (3-5 days), with air and sea freight options

- ESD-Safe Packaging: Moisture barrier bags to protect your PCBs during shipping

- Comprehensive Customer Support: Dedicated account managers, engineering assistance, production updates, and after-sales support

By providing specialized support throughout the entire process—from design to delivery—we help ensure that your Rogers printed circuit board projects are completed on time, within budget, and with the highest quality standards.

Frequently Asked Questions

Q1: What are Rogers printed circuit boards used for?

A: Rogers printed circuit boards are specialized for high-frequency applications (above 500MHz) including wireless communications, radar systems, satellite equipment, test instruments, and RF/microwave circuits where standard FR4 materials have excessive signal loss.

Q2: How much do Rogers printed circuit boards cost compared to FR4?

A: Rogers materials typically cost 3-5x more than FR4, but hybrid stackups (Rogers for RF layers, FR4 for digital layers) can reduce costs significantly. Total pricing depends on layer count, size, and quantities. Contact us for specific Rogers printed circuit board quotes.

Q3: What is the typical lead time for Rogers printed circuit board manufacturing?

A: Standard lead times are 12-18 working days for fabrication and assembly. Quick-turn prototype service is available in 5-7 days. Volume orders may require 3-4 weeks depending on quantities and material availability.

Q4: Can you manufacture Rogers printed circuit boards with fine-pitch components?

A: Yes, our SMT assembly lines handle 01005 passives, 0.3mm pitch QFNs, and fine-pitch BGAs. We have specialized equipment and procedures for assembling delicate components on Rogers printed circuit boards.

Q5: Do you provide design services for Rogers printed circuit boards?

A: We provide DFM review, stackup optimization, and impedance calculation services. For complete PCB design, we can recommend trusted design partners. Our engineering team ensures your Rogers printed circuit board design is optimized for manufacturing and performance.