Rogers RO3000 series offers low-loss PCB technology for high-frequency circuits, supporting applications from 1 GHz to 77+ GHz. Ideal for 5G mmWave, satellite communication, and military radar, RO3000 provides exceptional electrical performance, temperature stability, and mechanical reliability.

Made with a PTFE-based ceramic composite laminate, RO3000 outperforms traditional FR4 and even other high-frequency materials like Rogers RO4000. With different grades such as RO3003, RO3010, and RO3035, it allows for precise material selection based on your specific needs.

Explore more about high-frequency designs in our High-Frequency PCB section, or check out our Rogers PCB offerings for tailored solutions.

Why Choose Rogers RO3000 for RF and Microwave Circuits?

Understanding the properties of Rogers RO3000 helps engineers select the best material for their high-frequency and low-loss applications. Below are some of the key features of Rogers RO3000 and why it is the preferred choice for RF circuits.

Ultra-Low Loss Tangent

One of the most important features of the Rogers RO3000 series is its ultra-low loss tangent, which ensures minimal signal loss during transmission. This is crucial for high-frequency circuits where even the smallest loss can significantly degrade performance.

Loss Tangent Comparison at 10 GHz:

- Standard FR4: 0.020-0.025

- Rogers RO4000: 0.0037

- RO3003: 0.0013

- RO3010: 0.0022

In practical terms, this means that a 3-inch microstrip transmission line at 28 GHz using RO3003 will experience a 0.5 dB improvement in insertion loss over RO4350B. This 0.5 dB improvement can provide up to a 12% increase in link margin in 5G mmWave communications, which is critical for ensuring reliable data transmission over long distances.

Temperature-Stable Dielectric Properties

RO3000 maintains a highly stable dielectric constant across a wide temperature range. This is particularly important for applications that operate in extreme environments, such as aerospace, military radar, and satellite communications.

RO3003 Specifications:

- Dielectric Constant (εr): 3.00 ± 0.04 at 10 GHz

- Temperature Coefficient of εr: -3 ppm/°C (essentially zero)

- Operating Temperature: -55°C to +200°C

- Frequency Stability: Stable from DC to 77+ GHz

For applications such as phased array antennas, where beam steering accuracy depends on maintaining phase relationships across hundreds of elements, temperature-induced shifts in εr could result in beam pointing errors. RO3000’s stability ensures that systems maintain their performance across a wide temperature range, from arctic cold to desert heat, without the need for temperature compensation.

Low Permittivity Options for Compact Designs

Rogers RO3000 offers lower dielectric constants compared to other high-frequency materials, providing additional flexibility in PCB design. This feature is crucial for minimizing the size of RF components while maintaining performance.

Material Options:

- RO3003: εr 3.00 (ideal for general designs)

- RO3010: εr 10.2 (higher permittivity for compact designs)

- RO3035: εr 3.50 (for compatibility with RO4350B designs)

By selecting the appropriate RO3000 grade, designers can optimize trace widths and reduce conductor loss, enhancing overall performance while meeting space and size constraints in complex systems like 5G base stations and satellite transceivers.

Applications of Rogers RO3000 PCBs

Rogers RO3000 is used in a wide range of high-performance applications that demand low loss, temperature stability, and mechanical reliability. Key applications include:

- 5G mmWave Infrastructure

- Military Radar Systems

- Satellite Communication Systems

- Aerospace and Defense Systems

- Automotive Radar Systems

- High-Frequency Test Equipment

- Microwave and Millimeter-Wave Communication Systems

- Phased Array Antennas

- Medical Imaging and Diagnostics

- Broadcasting and Communication Equipment

- Wi-Fi and High-Speed Wireless Communication

- Precision Measurement Instruments

- Satellite Payload Electronics

Thermal Management in High-Power Applications

Effective thermal management is essential for high-power RF systems to prevent overheating and ensure long-term reliability. The RO3000 series provides high thermal conductivity, enabling efficient heat dissipation. This is critical for high-power applications such as radar systems, power amplifiers, and satellite communications.

Key strategies include:

- Thermal vias for heat dissipation.

- Wide copper traces to spread heat efficiently.

- Metal-core PCBs to effectively transfer heat from components.

These measures ensure that sensitive components remain within safe temperature limits, preventing damage and ensuring optimal performance.

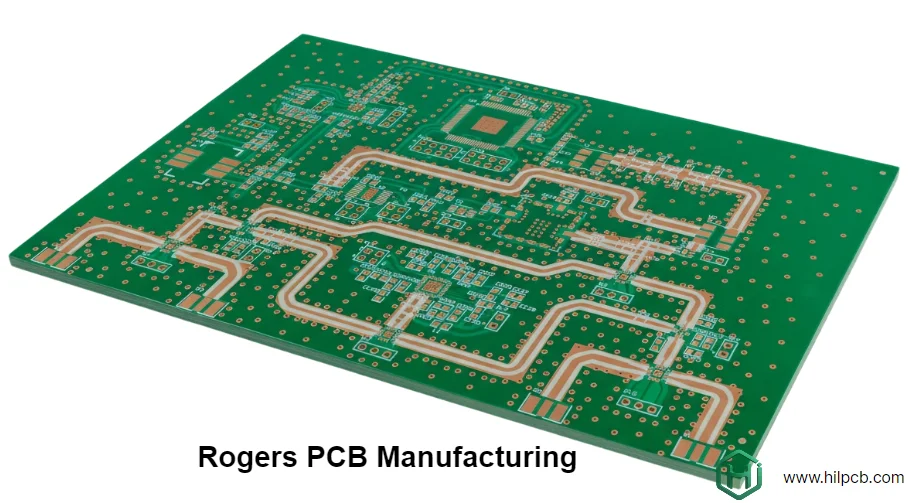

Design and Manufacturing Considerations

Design Rules for RO3000

Optimizing RO3000’s performance requires adjusting design rules compared to standard materials like FR4. Here are the key considerations:

- Trace Width: Wider traces are necessary to reduce resistance and losses, especially in high-frequency, high-power applications.

- Via Design: Larger vias are needed to handle higher current and prevent heat buildup. Proper via design ensures signal integrity.

- Ground Plane Management: Continuous ground planes minimize noise and interference, maintaining stable signal integrity across layers.

Manufacturing Challenges

Due to the PTFE-based composition of RO3000, specific challenges arise in the manufacturing process:

- Drilling: Requires high-precision carbide drill bits to avoid material smearing and ensure clean hole formation for vias.

- Lamination: Strict temperature and pressure control is necessary to prevent warping and ensure uniform bonding between layers.

- Surface Treatment: RO3000’s low surface energy requires plasma or chemical treatment to ensure strong adhesion of copper, soldermask, and other coatings.

Quick Turnaround for Custom Rogers RO3000 PCBs

In today’s fast-paced market, timely delivery of custom PCBs is essential for ensuring product success and meeting tight project timelines. Delays can affect the overall development process, causing bottlenecks and increasing time-to-market. At HILPCB, we focus on providing efficient, reliable, and comprehensive solutions to support your project at every stage, from design to delivery.

Key elements of our comprehensive PCB manufacturing and assembly services include:

- Streamlined Manufacturing Process: Our efficient and highly automated manufacturing process ensures your custom Rogers RO3000 PCBs are produced with precision and speed. We handle everything from initial design to final production.

- Flexible Manufacturing Capabilities: We have the capacity to produce a wide range of PCB types, including single-layer, multi-layer, HDI, rigid-flex, and Rogers-based boards, meeting your specific requirements for each project.

- Turnkey Assembly Services: We offer full PCB assembly services, including surface-mount technology (SMT), through-hole technology (THT), and mixed technology, ensuring seamless integration of components into your board.

- One-Stop Solution: Our all-in-one approach allows you to manage everything from PCB design, fabrication, assembly, and testing to final product delivery. You don’t need to rely on multiple suppliers, reducing complexity and ensuring smooth project execution.

- Delivery and Logistics Assurance: We guarantee on-time delivery through optimized logistics processes and partnerships with trusted shipping carriers. We ensure your order reaches you on time, with clear tracking and shipping updates throughout the process.

- Reliable After-Sales Support: Our commitment doesn’t end at delivery. We offer comprehensive after-sales support, including product testing, troubleshooting, and technical assistance to ensure your PCBs perform flawlessly in their application.

By integrating these elements into our service offerings, we provide you with a reliable, efficient, and fully supported PCB manufacturing experience. Whether you need quick-turn prototypes, large production runs, or complete assembly services, we ensure your project moves forward on time, with quality you can depend on.