As microwave and high-frequency systems push the limits of power and precision, Rogers TMM™ PCB materials have become the preferred choice for engineers seeking dimensional stability, low dielectric loss, and thermal reliability. At HILPCB, we combine advanced fabrication control with expert assembly services to produce TMM-based PCBs that meet the exacting requirements of aerospace, satellite, automotive radar, and 5G communication applications.

With years of experience processing TMM3, TMM6, and TMM10i, our team ensures unmatched consistency in dielectric behavior, copper adhesion, and via reliability across all frequency bands.

Understanding Rogers TMM PCB Technology

Rogers TMM (Thermoset Microwave Materials) are engineered composites that blend ceramic fillers with thermoset polymer resins, providing electrical precision comparable to PTFE while maintaining superior mechanical strength and process stability.

Key Electrical and Thermal Advantages

- Dielectric Constant (Dk 3.27 – 12.85): Enables precise impedance control for high-frequency PCB and antenna circuits.

- Low Loss Tangent (Df ≈ 0.002): Reduces insertion loss, essential for radar and microwave links.

- Thermal Conductivity (≈ 0.7 W/m·K): Enhances heat dissipation for high-power amplifiers.

- Copper-Matched CTE: Prevents delamination and via fatigue under thermal cycling.

- Moisture Absorption < 0.2 %: Guarantees stability in humid, marine, or outdoor systems.

Unlike standard PTFE boards, TMM substrates resist creep and cold flow, allowing tighter mechanical tolerances in multilayer PCB and stacked structures.

Engineering and DFM for High-Frequency Performance

Producing high-reliability Rogers TMM PCBs requires fine control over each step — from lamination pressure to copper plating. HILPCB’s Design-for-Manufacturability (DFM) process ensures predictable signal performance and repeatable yields.

Our DFM Optimization Process

- Pre-layout stack-up simulation to model impedance and signal paths before tooling.

- Precision drilling using optimized feeds to reduce chipping on ceramic-filled layers.

- Sequential lamination with temperature-controlled curing for dimensional stability.

- Laser microvia formation for stacked-via HDI PCB designs.

- RF-grade surface finishes (ENIG / ENEPIG) ensuring low contact resistance.

- Comprehensive validation: impedance, S-parameter, and insertion-loss testing.

Through continuous DFM feedback, every board achieves the performance margins needed for mission-critical RF assemblies.

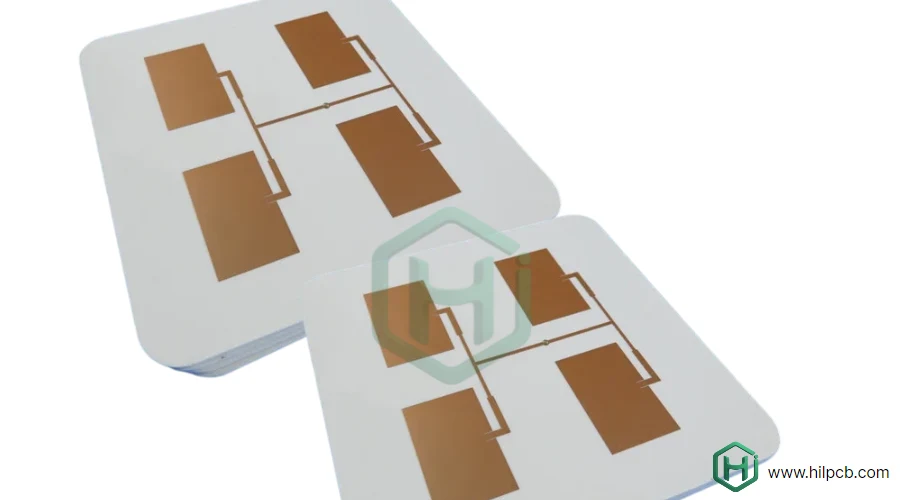

Hybrid Material Integration and Stack-Up Design

TMM laminates can be strategically combined with FR-4 or polyimide materials to balance cost, performance, and manufacturability. HILPCB specializes in hybrid stack-ups that merge microwave-grade layers with standard digital or power sections.

Hybrid Construction Highlights

- Multi-material stackups: TMM for RF layers, FR4 PCB for logic and power.

- Thermal transition zones: Integration with high-thermal PCB layers for power-intensive designs.

- Controlled impedance transitions: Smooth RF-to-digital routing between materials.

- Ground isolation via fences: EMI reduction in mixed-signal modules.

- Lamination matching: Balanced CTE control for reliable bonding.

These hybrid structures provide the flexibility to support radar sensors, mixed-signal communication modules, and compact rigid-flex PCB configurations.

Applications Across Industries

Rogers TMM PCBs are indispensable in environments where signal integrity, thermal management, and structural stability are equally important.

Key Industry Applications

- Automotive Radar (77 GHz / 79 GHz): Used in ADAS and object-detection modules with low phase error.

- 5G and Telecom: Low-PIM, low-loss substrates for beamforming and base-station arrays.

- Aerospace and Satellite: Radiation-resistant materials that maintain electrical properties in orbit.

- Defense and Radar Systems: Supports phased-array antennas and high-power transmitters.

- Industrial and Medical Equipment: Ensures measurement accuracy in imaging, spectroscopy, and RF testing.

For these applications, HILPCB also provides integration with metal-core PCB platforms to improve heat spreading in high-density modules.

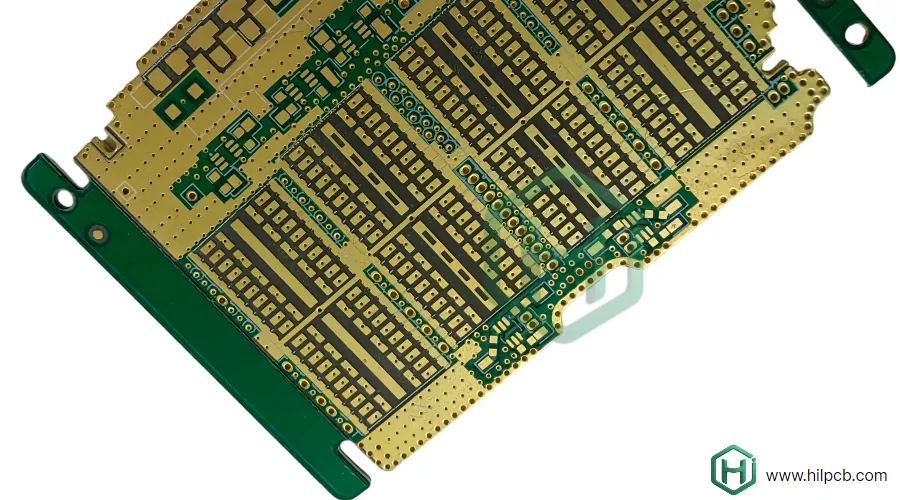

Manufacturing and Assembly Expertise at HILPCB

Our dedicated TMM production line combines advanced lamination, copper plating, and testing capabilities, supporting both prototype and volume manufacturing.

Capabilities Overview

- TMM Inventory: TMM3, TMM6, TMM10i and TMM10 for rapid build cycles.

- Microvia and Backdrill Control: Eliminates stubs in high-speed PCB architectures.

- Precision Inspection: AOI, X-ray, and cross-section analysis for via quality.

- Environmental Stress Testing: Thermal cycling (−40 °C to +150 °C) and humidity validation.

- Assembly Integration: From SMT assembly to turnkey assembly, all handled under one roof.

This end-to-end control guarantees manufacturing repeatability, fast lead times, and consistent signal quality — critical for RF and microwave system developers worldwide.

Partnering with HILPCB for Rogers TMM PCB Projects

HILPCB offers full-cycle support — from design consultation and prototyping to production and long-term supply. Our engineers collaborate closely with customers to ensure that every Rogers TMM PCB meets its mechanical, electrical, and environmental goals.

Why Global OEMs Choose HILPCB

- One-stop service: Integrated fabrication + assembly + testing.

- Material expertise: Deep understanding of TMM, Rogers, and hybrid substrates.

- Scalable production: From small-batch assembly to mass manufacturing.

- Certified quality: ISO 9001 / IATF 16949 / IPC Class 3 compliance.

- Technical support: DFM, stack-up, impedance, and reliability guidance throughout development.

By combining microwave engineering know-how with precision manufacturing, HILPCB enables companies to accelerate innovation and deliver high-performance RF solutions to market with confidence.