Space-grade electronics face the most demanding operational environment imaginable—extreme temperature swings, intense radiation exposure, vacuum conditions, and zero tolerance for failure. Satellite PCBs must function flawlessly for missions lasting 15+ years without the possibility of repair or maintenance, making reliability the paramount design criterion.

Our specialized Satellite PCB manufacturing capabilities address these unique challenges through radiation-hardened materials, extreme-temperature processing, rigorous quality protocols, and comprehensive testing that validates performance under actual space conditions.

What Makes Satellite PCBs Unique?

Satellite PCBs are designed for extreme conditions, ensuring reliability and performance in environments that would damage commercial electronics.

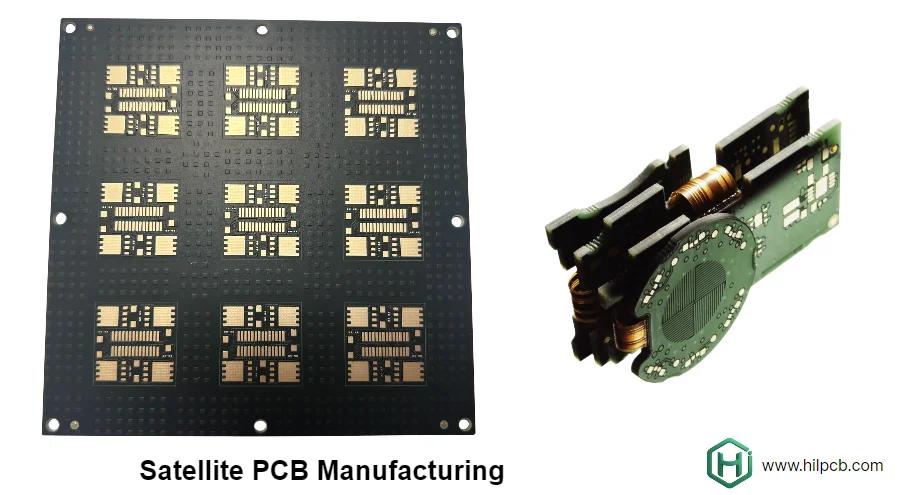

Mission-Critical Reliability: Space missions involve multi-year development with high stakes. A PCB failure can jeopardize the entire mission. Our process includes screening, burn-in testing, X-ray inspection, thermal cycling, vibration testing, and functional validation, all based on high reliability PCB standards and space-specific requirements like NASA and ESA specifications.

Environmental Extremes: Satellites endure extreme temperature fluctuations and radiation. Thermal cycling can cause material expansion and PCB cracking. Radiation causes single-event upsets and gradual damage. Our designs ensure robust protection against these challenges.

Vacuum and Outgassing: Materials must pass NASA's outgassing tests (ASTM E595), ensuring minimal contamination of sensitive equipment like optics and solar panels.

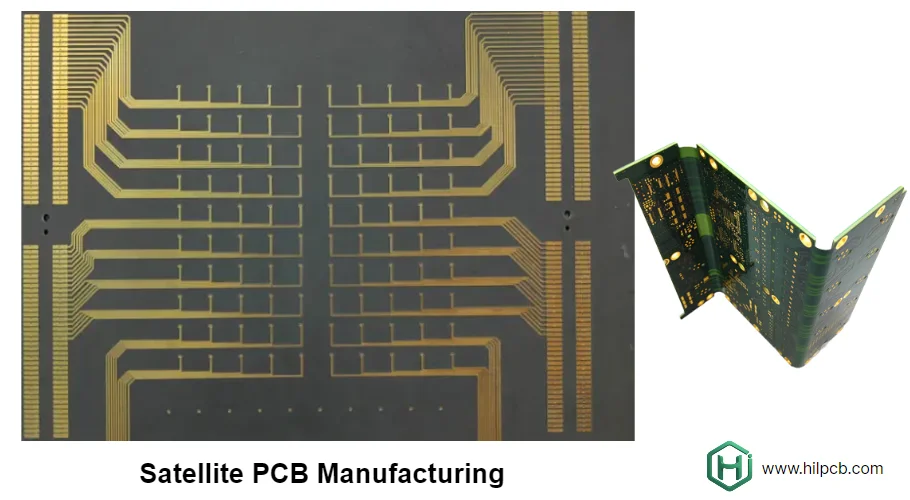

**Mechanical Stress During Launch: **Launch forces exceeding 8G and intense vibration can damage electronics. Our rigid-flex PCB designs provide flexibility and reduce mechanical stress, improving launch survival rates.

Designing for Radiation Resistance in Space Environments

Radiation is a major challenge for satellite electronics, with high-energy particles causing immediate or long-term circuit failure. Effective design ensures components withstand radiation exposure, maintaining functionality throughout the satellite's mission.

Understanding Space Radiation

Space radiation primarily comes from:

- Solar particle events (SPE): Protons during solar storms

- Van Allen belts: Trapped radiation around Earth

- Galactic cosmic rays (GCR): Background high-energy particles

The radiation dose varies based on orbital altitude and mission duration. Satellites in low-Earth orbit (LEO) receive 5-15 krad over five years, while those in geostationary orbit (GEO) may experience 50-100 krad.

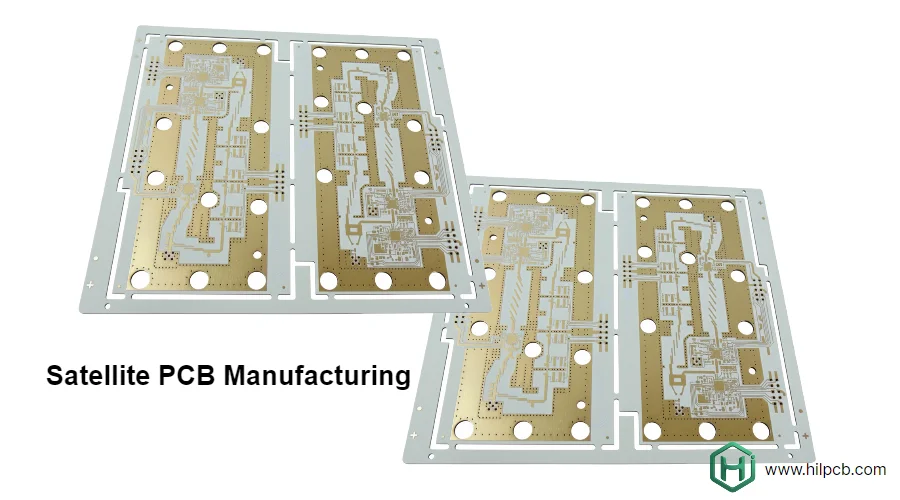

Material Selection for Radiation Tolerance

Standard FR4 materials degrade under radiation, becoming brittle after absorbing 50-100 krad. Space-grade materials like cyanate ester or bismaleimide-triazine (BT) resins offer higher radiation resistance, maintaining integrity up to 1 Mrad. Additionally, polyimide-based flex PCBs, such as Kapton, provide excellent radiation resistance while maintaining flexibility.

Circuit Design Strategies

To minimize radiation-induced damage, we use:

- Differential signaling to reject radiation transients

- Redundant circuit paths and error detection to ensure reliability

- Radiation-hardened-by-design (RHBD) techniques for critical nodes

These strategies enable the use of commercial components in space applications, reducing costs compared to fully radiation-hardened parts.

Shielding Approaches

When circuit-level measures aren’t enough, physical shielding offers added protection:

- Spot shielding: Using metal cans or coatings for sensitive components

- Area shielding: Copper pours on inner layers to block radiation

- Multilayer PCBs often include dedicated shielding planes for radiation protection, not just grounding.

By employing these design and material strategies, we ensure satellite PCBs perform reliably in harsh space environments, maintaining functionality and reducing failure rates.

Choosing the Right Materials for High Temperature Resistance

Satellite electronics must endure both the extreme temperatures of space and the elevated temperatures during launch, where enclosed bays can reach +85°C.

Key elements of our high-temperature resistance strategy for satellite PCBs include:

- High-Tg Laminates with a minimum Tg ≥ 170°C, ensuring stability and preventing warping or delamination during thermal testing and in-orbit operation.

- Polyimide Materials, such as Kapton, which can operate continuously at 260°C, ideal for heat-generating components like power amplifiers and propulsion electronics.

- CTE Matching to reduce thermal stress during cycling, using low-CTE laminates (8-12 ppm/°C) and ceramic PCB substrates that perfectly match the CTE of ceramic components.

- Heavy Copper (3 oz/ft² to 6 oz/ft²) in power areas, improving heat dissipation while minimizing CTE mismatch stress in signal areas. Our heavy copper PCB manufacturing ensures reliable plated through-holes even with thick copper layers.

- Coating and Conformal Protection with space-grade coatings like parylene or silicone to prevent moisture absorption and provide mechanical support during launch.

By employing these strategies, we ensure satellite PCBs perform reliably in space, even in extreme thermal environments, helping extend mission lifetimes and maintaining system stability.

Streamlining Your Satellite PCB Order

At HILPCB, we simplify the complex process of manufacturing space-grade PCBs, ensuring all requirements are met with precision, efficiency, and reliability throughout every phase—from design to delivery. We also prioritize confidentiality, ensuring that all your project details and intellectual property are handled with the utmost care.

Key steps in our comprehensive process include:

- Requirements Definition: We begin by thoroughly understanding the mission profile, including orbit type, temperature range, radiation dose, and mechanical loads (e.g., launch vehicle specifications). This ensures that environmental extremes and program-specific standards are clearly documented at the outset, preventing surprises in the later stages of the project. We also ensure that all information shared during this phase is handled with strict confidentiality, protecting your intellectual property and mission details.

- Rapid Prototyping: Initial designs are validated using flight-equivalent materials and processes. Prototype PCBs are manufactured under the same stringent controls as flight-ready units, ensuring they closely match the final product’s electrical and mechanical performance. This step also includes confidential handling of all design documents to safeguard sensitive information.

- Qualification and Flight Production: After prototypes are validated, the boards undergo extensive testing, including thermal cycling, vibration, shock testing, and radiation exposure (as required). Following successful qualification, production is initiated with consistent quality control to meet the high standards required for satellite operations. All processes are conducted under strict confidentiality to protect both the design and production data.

- Design Support and Consultation: Throughout the project, our engineering team provides continuous support to optimize stack-up design, material selection, and thermal analysis. Our experts ensure your PCBs meet mission requirements while also optimizing for manufacturability and cost-efficiency. We also ensure all communications and collaboration are protected, maintaining confidentiality throughout the process.

- Final Delivery and Long-Term Support: Your satellite PCBs will be delivered on time, complete with all necessary documentation, including certificates of conformance and quality assurance reports. We maintain 15+ years of production documentation for ongoing mission support and potential anomaly investigations. Additionally, we ensure all post-delivery support is conducted under strict confidentiality to protect your mission data.

We take confidentiality seriously, ensuring that every phase of the process—design, manufacturing, testing, and delivery—is handled securely, with your proprietary information safeguarded at every step.

Comprehensive Solutions for Space Electronics

Successful satellite programs require more than high-quality PCBs—they demand a manufacturing partner with deep understanding of space environment challenges and commitment to the rigorous quality practices essential for mission success.

Our space electronics capabilities include:

- High-reliability PCB fabrication to IPC-6012 Class 3/A and NASA standards

- Material qualification and outgassing testing per ASTM E595

- Radiation testing coordination and radiation-hardness analysis

- Precision SMT assembly with space-qualified processes and materials

- Conformal coating application with process controls for space compatibility

- Complete documentation packages supporting program acceptance reviews

- Long-term material storage and production repeatability for multi-year programs

We support satellite programs from early concept development through on-orbit operations, providing the technical expertise and manufacturing quality essential for mission success. Our experience spans commercial communications satellites, Earth observation platforms, scientific missions, and defense space systems.

Whether your mission requires small batch assembly for experimental payloads or turnkey assembly of complete spacecraft subsystems, we deliver the reliability and performance your mission demands.