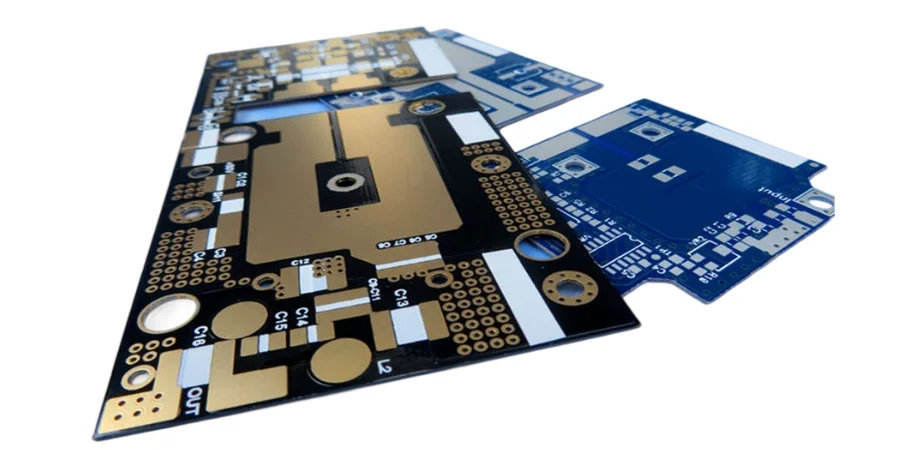

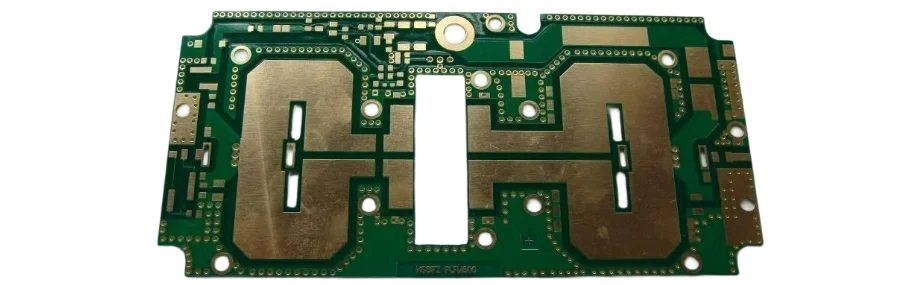

Highleap PCB Factory (HILPCB) specializes in manufacturing premium Taconic PCBs for demanding RF, microwave, and millimeter-wave applications. Our expertise with Taconic's advanced PTFE-based materials, combined with specialized processing capabilities, delivers circuit boards that excel in telecommunications, aerospace, defense, and satellite communications where signal integrity is paramount.

Advanced Taconic Materials and Their Unique Properties

Taconic Advanced Dielectric Division produces specialized PTFE (polytetrafluoroethylene) based laminates engineered for superior electrical performance at high frequencies. Our Taconic PCB manufacturing encompasses their complete portfolio:

Ultra-Low Loss Materials

- Taconic TLX Series: Featuring Dk values from 2.45-2.65 and ultra-low Df of 0.0019 at 10 GHz

- Taconic TLY-5: Lightweight material with Dk of 2.20 and exceptional dimensional stability

- Taconic TLC Series: Low-cost PTFE option maintaining excellent RF performance

Ceramic-Filled PTFE Systems

- Taconic RF-35: Industry-standard material with Dk of 3.50 and superior plated hole reliability

- Taconic CER-10: High dielectric constant (Dk=10) for miniaturized antenna designs

- Taconic RF-60A: Enhanced thermal conductivity (0.66 W/m·K) for power amplifier applications

These Taconic laminate materials enable breakthrough performance in 5G infrastructure, satellite communications, automotive radar, and military electronics. The inherent properties of PTFE - including moisture absorption below 0.02%, stable electrical characteristics over frequency, and excellent phase stability - make Taconic circuit boards ideal for mission-critical applications.

Specialized Manufacturing Processes for Taconic PTFE PCBs

Manufacturing Taconic PCBs requires fundamentally different processes compared to standard FR-4 due to PTFE's unique properties. Our dedicated PTFE processing line incorporates:

Surface Preparation Technology: PTFE's non-stick properties demand specialized surface treatments. We employ sodium naphthenate etching or plasma treatment to modify the PTFE surface, creating micro-roughness that ensures copper adhesion exceeding 6 N/cm peel strength.

Controlled Lamination: Taconic materials require precise temperature ramping to 370°C with controlled pressure profiles. Our hydraulic presses feature multi-zone heating with ±2°C uniformity, preventing material flow while achieving void-free lamination essential for consistent dielectric properties.

Precision Drilling: PTFE's soft, deformable nature requires specialized drilling parameters. We utilize controlled-depth drilling with optimized chip loads, preventing smear and ensuring clean hole walls. Entry and exit materials are carefully selected to minimize burring and fiber pull-out.

Taconic PCB Excellence in RF and Microwave Design

Impedance Control and Signal Integrity

Taconic PCBs excel in maintaining precise impedance control crucial for RF applications. Our manufacturing processes achieve:

- Impedance tolerance of ±5% (±3% available for critical applications)

- Dielectric thickness control within ±0.025mm

- Consistent copper surface roughness for predictable insertion loss

- Edge-plating for improved grounding in high-frequency PCB designs

Advanced modeling using 3D electromagnetic simulation ensures accurate prediction of transmission line behavior, including dispersion effects and higher-order modes. Our engineering team provides pre-layout simulation support to optimize trace geometries for your specific frequency bands.

Thermal Management in Power Applications

High-power RF applications benefit from Taconic's thermally enhanced materials like RF-60A and RF-35A. These ceramic-filled PTFE substrates combine low loss with improved thermal conductivity, essential for power amplifiers and active antenna arrays. Our manufacturing capabilities include:

- Thermal via arrays for efficient heat transfer

- Direct copper bonding for enhanced thermal performance

- Integration with metal core PCB technology for extreme thermal loads

- Selective plating for optimized current distribution

Comprehensive Taconic PCB Manufacturing Capabilities

With a monthly output encompassing hundreds of Taconic board types, HILPCB supports a broad spectrum of RF and microwave technologies:

Technical Specifications

- Layer count: 1-64 layers including multilayer PCB constructions

- Board thickness: 0.254mm to 8.0mm

- Copper weights: 0.5 oz to 4 oz (heavier copper available)

- Minimum features: 3/3 mil trace/space (2.5/2.5 mil for select materials)

- Via capabilities: Through-hole, blind/buried, and filled vias

Quick-Turn Services Understanding the urgency of prototype development, we offer:

- 48-72 hour delivery for standard 2-layer Taconic PCBs

- 5-7 day turnaround for multilayer designs

- Same-day quote generation with DFM feedback

- Engineering support for material selection and stackup optimization

Quality Assurance for Taconic PCB Manufacturing

Every Taconic PCB undergoes rigorous testing tailored to PTFE material characteristics:

Electrical Testing: Network analyzer measurements verify insertion loss, return loss, and phase characteristics. Time domain reflectometry confirms impedance uniformity along transmission lines.

Mechanical Validation: Peel strength testing ensures copper adhesion meets IPC-TM-650 requirements. Cross-sectional analysis verifies lamination quality and registration accuracy.

Environmental Testing: Thermal cycling (-55°C to +125°C) and humidity exposure validate long-term reliability. Outgassing tests for space applications confirm low volatile content.

We maintain full material traceability with certificates of conformance documenting dielectric constant, dissipation factor, and thickness measurements for each production lot.

Complete Taconic PCB Assembly Solutions

Beyond bare board fabrication, HILPCB provides specialized assembly services for Taconic substrates:

RF-Optimized Assembly

- Controlled atmosphere soldering to prevent oxidation

- Low-temperature processes for temperature-sensitive PTFE

- Precision die attachment for MMIC integration

- Wire bonding with gold or aluminum for microwave frequencies

Our turnkey assembly services include component sourcing from authorized distributors specializing in RF/microwave parts. We maintain relationships with suppliers of specialized connectors, attenuators, and passive components designed for high-frequency applications.

Global Delivery and Engineering Support

HILPCB's commitment to customer success extends beyond manufacturing:

Logistics Excellence

- Worldwide shipping via DHL, FedEx, and UPS

- Vacuum-sealed packaging to prevent moisture absorption

- Temperature-controlled storage for sensitive materials

- Customs documentation for international shipments

Technical Partnership

- Free DFM review by RF-experienced engineers

- Stack-up recommendations for optimal performance

- Material selection guidance based on application requirements

- Post-delivery support for assembly and testing

Payment Flexibility

- Multiple payment options including PayPal and wire transfer

- NET terms for established accounts

- Competitive pricing with volume discounts

- No hidden fees or minimum order charges

Why Choose HILPCB for Taconic PCB Manufacturing

Selecting the right manufacturer for Taconic PCBs directly impacts product performance. Our advantages include:

- PTFE Expertise: Dedicated equipment and processes for PTFE materials

- RF Knowledge: Engineers experienced in microwave circuit design

- Quality Systems: ISO 9001, IATF 16949, and AS9100 certified

- Fast Turnaround: Industry-leading delivery times

- Complete Solutions: From prototypes through volume production

- Global Reach: Serving customers in 60+ countries

Partner with HILPCB for your Taconic PCB requirements and experience the difference of working with RF/microwave specialists. Whether you need Taconic TLX for ultra-low loss applications, RF-35 for general microwave circuits, or high-dielectric materials for antenna miniaturization, we deliver exceptional quality that meets your exact specifications.

Frequently Asked Questions

What makes Taconic materials different from standard PCB substrates?

Taconic materials use PTFE (Teflon) base with ceramic fillers, providing exceptional electrical properties including ultra-low loss (Df as low as 0.0019), stable dielectric constant over frequency and temperature, and near-zero moisture absorption. These properties make them ideal for frequencies above 1 GHz where standard FR-4 exhibits excessive losses.

How do you handle the dimensional stability of Taconic PTFE materials?

PTFE materials have higher CTE than FR-4, requiring special handling. We use controlled lamination cycles, balanced copper distributions, and stress-relief processes. For critical applications, we recommend materials like TLX-8 or TLY-5A with woven glass reinforcement for improved dimensional stability.

Can Taconic PCBs be combined with other materials in hybrid stackups?

Yes, we regularly manufacture hybrid multilayer boards combining Taconic materials with FR-4 or other substrates. This approach optimizes cost by placing expensive Taconic materials only on RF layers while using standard materials for digital/power layers. Special bonding films ensure reliable adhesion between dissimilar materials.

What surface finishes work best with Taconic PCBs?

For RF applications, we recommend immersion silver or ENIG (Electroless Nickel Immersion Gold) for optimal high-frequency performance. These finishes provide excellent solderability while minimizing insertion loss. For extreme environments, we offer selective gold plating on critical RF traces.

How tight can trace width tolerances be held on Taconic materials?

We achieve ±0.025mm (±1 mil) trace width tolerance on most Taconic materials. The soft nature of PTFE requires optimized imaging and etching processes. For impedance-critical designs, we recommend slightly relaxed geometries compared to FR-4 to ensure consistent manufacturing yields.

What are typical lead times for Taconic PCB orders?

Standard 2-layer Taconic PCBs ship in 5-7 days. Complex multilayer boards require 10-15 days depending on stackup complexity. We stock common Taconic materials to minimize procurement delays. Expedited 48-72 hour service is available for prototype quantities.

Do you provide design assistance for Taconic PCB layouts?

Yes, our RF engineering team offers free design review services including impedance calculations using impedance calculator tools, stackup optimization, and material selection guidance. We can simulate your design's performance and suggest improvements for manufacturability and electrical performance.

What testing capabilities do you have for Taconic PCBs?

We perform S-parameter measurements up to 40 GHz, TDR impedance profiling, insertion loss testing, and phase stability verification. Environmental testing includes thermal cycling, humidity testing, and vibration analysis. All test data is provided with your shipment for quality verification.