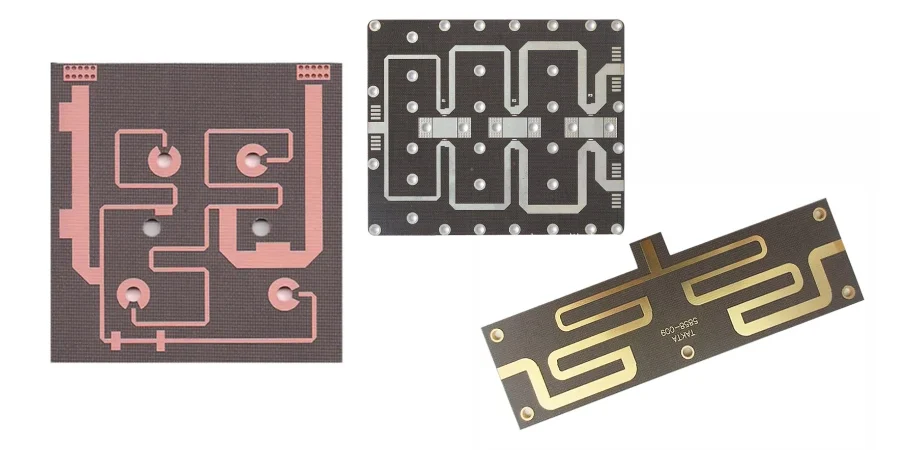

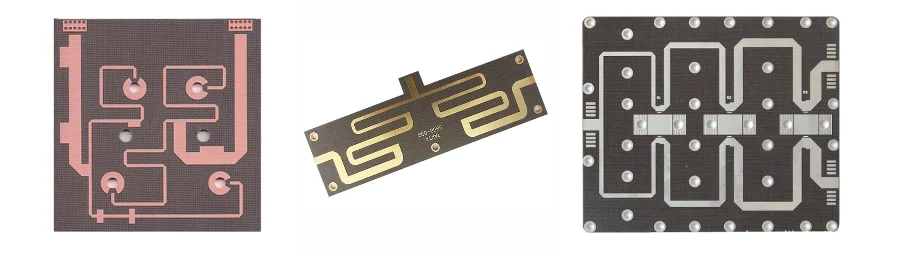

As a leading Teflon PCB manufacturer, we specialize in producing high-performance PTFE-based circuit boards for demanding RF, microwave, and millimeter-wave applications. Our advanced manufacturing capabilities, combined with extensive experience processing Teflon materials, ensure superior quality and rapid delivery for your critical high-frequency PCB projects. High-quality Teflon PCB manufacturer for RF and microwave needs. Fast delivery, precision builds, and full assembly support.

Understanding Teflon PCB Materials and Properties

Teflon PCBs utilize PTFE (polytetrafluoroethylene) based substrates that deliver exceptional electrical performance for high-frequency applications. With dielectric constants ranging from 2.1 to 10.2 and dissipation factors as low as 0.0009, Teflon circuit boards provide minimal signal loss and stable performance across wide frequency ranges. The material's hydrophobic nature results in moisture absorption below 0.01%, ensuring consistent electrical properties even in humid environments.

We process all major Teflon PCB materials including pure PTFE, ceramic-filled PTFE, and woven glass reinforced PTFE composites. Our inventory encompasses Rogers RT/duroid series, Taconic TLY and RF series, Arlon DiClad, and other premium PTFE laminates. The low coefficient of thermal expansion and excellent dimensional stability of Teflon materials enable reliable performance from -200°C to +260°C, making them ideal for aerospace, defense, and telecommunications applications.

Specialized Manufacturing Processes for Teflon Circuit Boards

Manufacturing Teflon PCBs requires specialized expertise due to PTFE's unique properties. The material's softness and tendency to deform demand precise control during drilling operations. We utilize high-speed spindles operating at 70,000-100,000 RPM with specialized drill geometries to achieve clean hole walls without smearing. Our controlled drilling parameters, including optimized feed rates and pecking cycles, ensure reliable plated through-hole connections essential for signal integrity.

Surface preparation represents a critical step in Teflon PCB fabrication. The naturally non-stick PTFE surface requires sodium etching or plasma treatment to enable copper adhesion. Our advanced plasma systems create uniform surface activation while maintaining the substrate's electrical properties. The subsequent metallization process employs specialized chemistry optimized for PTFE materials, achieving peel strength exceeding 8 pounds per inch for long-term reliability.

Why Choose Teflon PCBs Over Standard Materials

Superior Electrical Performance Teflon PCBs excel in applications where conventional FR-4 PCB materials fall short. The ultra-low loss tangent of PTFE enables efficient signal transmission at frequencies exceeding 100 GHz, critical for 5G infrastructure, satellite communications, and radar systems. Unlike standard materials, Teflon maintains stable electrical properties across temperature extremes and exhibits virtually no moisture absorption, ensuring consistent performance in outdoor and space applications.

Thermal and Chemical Advantages The superior thermal characteristics of Teflon PCBs support high-power RF applications without performance degradation. The material's low dielectric constant reduces signal propagation delay, enabling faster edge rates in high-speed PCB designs. Additionally, Teflon's chemical inertness provides exceptional resistance to solvents, fuels, and corrosive environments, extending product lifetime in harsh industrial applications.

Cost-Performance Optimization While Teflon PCBs command premium pricing compared to standard materials, the total cost of ownership often favors PTFE in high-frequency applications. Reduced insertion loss translates to lower power consumption and simplified thermal management. The material's durability minimizes field failures and warranty claims. For hybrid designs, we offer selective use of Teflon in critical RF sections combined with cost-effective materials elsewhere, optimizing both performance and budget.

Critical Applications Leveraging Teflon PCB Technology

Aerospace and Satellite Systems From aerospace radar systems to satellite transponders, Teflon PCBs enable breakthrough performance in space-qualified applications. Satellite communication systems utilize Teflon circuit boards for low-noise amplifiers, frequency converters, and phased array antennas operating at Ka-band and above. The material's minimal outgassing characteristics and radiation resistance ensure reliable operation in vacuum environments through extended missions.

5G and Telecommunications Infrastructure In the rapidly evolving 5G landscape, Teflon PCBs form the backbone of massive MIMO antennas, beamforming networks, and millimeter-wave transceivers. Our manufacturing processes maintain phase matching within ±2 degrees across antenna elements, critical for maintaining radiation pattern integrity. Base station equipment leverages Teflon's low loss for power amplifiers and filter networks operating at 28 GHz and 39 GHz bands.

Automotive Radar and Medical Devices Automotive radar sensors operating at 77 GHz leverage Teflon's low loss and temperature stability for reliable object detection in all weather conditions. The material's performance from -40°C to +125°C supports under-hood installations without degradation. Medical applications benefit from Teflon's biocompatibility and electrical performance - MRI coils utilize non-magnetic PTFE substrates, while microwave ablation devices rely on consistent dielectric properties for precise energy delivery.

Rapid Prototyping and Volume Production Capabilities

Time-to-market pressures demand responsive manufacturing partners. Our quick-turn Teflon PCB service delivers 2-layer prototypes in 48-72 hours for standard configurations, with multilayer PCB options available within 5-7 days. We maintain strategic inventory of common Teflon materials including RT/duroid 5880, RO3003, and TLY-5 to eliminate procurement delays and accelerate your development timeline.

Production volumes scale seamlessly from prototype quantities to thousands of boards monthly. Our advanced CAM software optimizes panel utilization while accounting for PTFE material movement during processing. Standard production lead times range from 7-10 days with expedite options available. We leverage automated handling systems designed specifically for soft PTFE materials, ensuring consistent quality throughout production runs while minimizing material waste and cost.

Quality Assurance and Comprehensive Testing

Every Teflon PCB undergoes rigorous inspection exceeding IPC-6012 Class 3 and IPC-6018 requirements for high-frequency boards. Our comprehensive quality protocol ensures reliable performance in mission-critical applications through multiple verification stages. Automated optical inspection systems detect surface anomalies with 0.001" resolution, while flying probe testers verify electrical continuity and isolation resistance across all nets.

For controlled impedance designs, we perform Time Domain Reflectometry (TDR) measurements at multiple locations, providing detailed reports showing actual versus specified values. Our impedance calculator helps optimize your stackup design before production. Additional testing includes peel strength verification, microsection analysis for plating quality, thermal stress screening, and coefficient of thermal expansion measurement to ensure dimensional stability.

Your Trusted Teflon PCB Manufacturer and Assembly Partner

Beyond Teflon PCB fabrication, we offer complete turnkey assembly services streamlining your supply chain from bare board to finished product. Our SMT lines equipped with vision-guided placement systems handle fine-pitch components with ±25 micron accuracy. Specialized reflow profiles account for PTFE's unique thermal properties, ensuring reliable solder joints without substrate damage. We manage component sourcing, programming, conformal coating, and functional testing, delivering fully validated assemblies ready for system integration.

Global shipping via DHL, FedEx, and UPS ensures timely delivery worldwide. Payment flexibility includes PayPal for quick transactions, wire transfers with competitive rates, and NET terms for qualified accounts. Our secure online portal provides instant quotes, real-time order tracking, and direct engineering communication throughout your project.

Partner with a Teflon PCB manufacturer committed to your success. Whether you need rapid prototypes, volume production, or complete assembly solutions, our team delivers exceptional quality, competitive pricing, and responsive support. Contact us today to discuss your Teflon PCB requirements and discover why leading technology companies choose us for their high-frequency circuit board needs.