Highleap PCB Factory (HILPCB) delivers comprehensive thermal cycling testing services ensuring exceptional reliability for PCB assemblies across demanding environmental conditions. Our advanced temperature stress protocols and precision thermal chambers provide thorough validation that identifies potential failures before deployment.

Advanced Thermal Cycling Testing Methodologies and Stress Analysis

Modern thermal cycling testing employs precisely controlled thermal profiles to accelerate failure mechanisms and validate operational stability through comprehensive stress protocols simulating real-world conditions.

Core Testing Technologies:

- Air-to-Air Thermal Cycling: Temperature transitions using forced convection systems achieving 5-15°C/minute across -65°C to +150°C ranges

- Liquid Thermal Shock Testing: Instantaneous temperature changes through immersion enabling extreme transition rates exceeding 50°C/second

- Gradient Temperature Cycling: Controlled ramping evaluating thermal expansion mismatches and mechanical stress accumulation

- Multi-Zone Profiling: Simultaneous exposure to different temperatures evaluating gradient effects and component interactions

- Coffin-Manson Modeling: Statistical analysis predicting field lifetime based on accelerated test results

- Real-time Monitoring: Continuous measurement of electrical parameters enabling early degradation detection

- Failure Mode Analysis: Investigation of thermal-induced mechanisms including CTE mismatches and material degradation

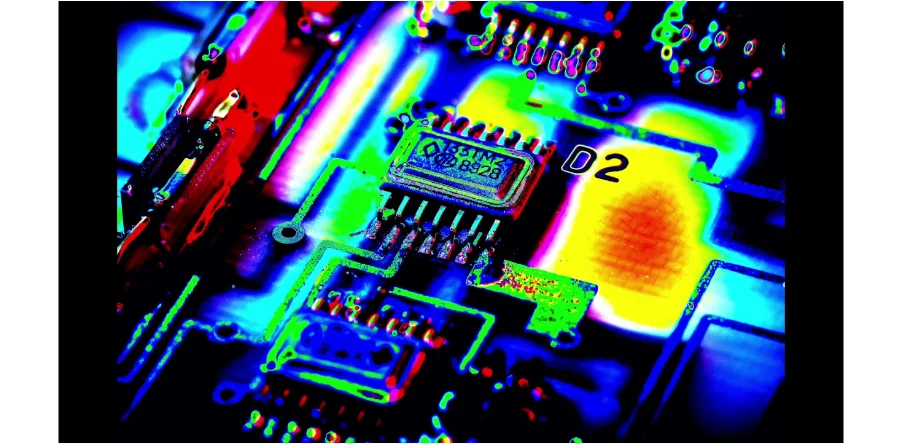

The physics leverages thermal expansion differences between materials to accelerate mechanical stress. Repeated expansion and contraction create cumulative fatigue in solder joints, vias, and interfaces. High-Tg PCB assemblies particularly benefit from validation due to elevated glass transition temperatures.

Manufacturing Integration and Assembly Reliability

Effective thermal cycling implementation requires seamless integration with manufacturing processes, enabling comprehensive verification while maintaining efficiency across diverse applications.

Production Integration: Testing optimization begins during design where material selection and layout influence stress distribution. Metal-core PCB assemblies require specialized protocols addressing enhanced heat dissipation characteristics. Integration includes automated chamber loading and data acquisition enabling high-throughput testing.

Assembly Considerations: SMT assembly operations integrate protocols addressing solder paste selection and reflow optimization under thermal stress. Testing programs evaluate process quality through statistical analysis of fatigue patterns. Turnkey assembly solutions incorporate comprehensive testing as integral quality verification.

Volume Optimization: Large-volume assembly operations utilize parallel chambers enabling simultaneous testing while maintaining individual monitoring capabilities. Risk-based approaches focus intensive testing on critical interfaces while maintaining overall quality standards.

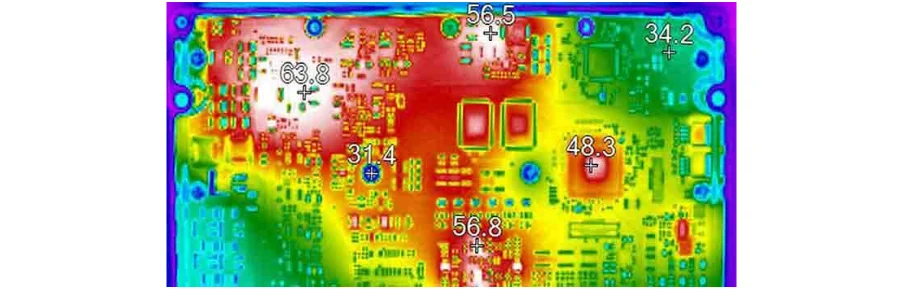

Temperature Stress Testing and Component Analysis

Comprehensive programs address diverse thermal mechanisms across components, providing detailed characterization supporting design optimization and quality decisions throughout development and manufacturing phases.

Solder Joint Evaluation: Protocols address fatigue mechanisms including intermetallic growth and expansion mismatch stress. Testing tracks joint temperature, resistance, and mechanical integrity enabling early fatigue detection. High-speed PCB applications require specialized testing addressing signal integrity under thermal stress.

Substrate Assessment: Testing evaluates expansion characteristics, delamination resistance, and dimensional stability. Systems monitor parameter changes during exposure, identifying variations and establishing predictions based on accelerated data.

Interface Validation: System-level testing evaluates via integrity, attachment reliability, and thermal interface performance under cyclic stress. Advanced diagnostics provide failure localization enabling rapid process improvement.

Standards and Quality Management

Professional operations adhere to comprehensive standards ensuring consistent verification while maintaining traceability supporting regulatory compliance.

Standards Compliance: Programs follow IPC-SM-785, JEDEC JESD22-A104, and MIL-STD-810. Standards define profiles, criteria, sampling requirements, and documentation protocols ensuring consistent verification across environments.

Statistical Analysis: Systems employ Weibull modeling, confidence calculations, and acceleration validation. Real-time control identifies variations enabling proactive management. Reporting includes failure summaries, predictions, and capability assessments.

Data Management: Facilities maintain databases tracking conditions, modes, and metrics enabling complete traceability. Systems support predictive modeling and trend analysis while maintaining secure storage.

Why Choose Highleap PCB Factory for PCB Manufacturing

As a leading China PCB factory, HILPCB combines advanced manufacturing capabilities with comprehensive thermal cycling testing, delivering exceptional quality and reliability for your electronic products. Our integrated approach ensures every PCB meets stringent performance standards while maintaining competitive pricing and reliable delivery.

Advanced Manufacturing and Testing Integration: State-of-the-art PCB production lines seamlessly integrated with thermal cycling testing facilities ensure complete quality verification. Professional expertise delivers optimized manufacturing processes validated through rigorous thermal stress protocols, guaranteeing product reliability under extreme conditions.

Comprehensive Quality Assurance: ISO 9001 certified manufacturing with integrated thermal cycling testing provides unparalleled quality control. From initial design review through final thermal validation, our engineering team ensures optimal material selection, process parameters, and testing protocols tailored to your specific requirements.

Efficient Production and Delivery: Streamlined workflows combining PCB fabrication, assembly, and thermal cycling testing reduce lead times while maintaining quality. Multiple payment options, secure international shipping, and responsive customer support ensure smooth project execution from prototype through volume production.

FAQ

What temperature ranges are typically used in thermal cycling testing? Standard testing employs -40°C to +85°C for commercial applications, -55°C to +125°C for military applications, and extended ranges to +150°C for specialized requirements. Transition rates typically range from 5-15°C/minute depending on acceleration factors.

How many thermal cycles are required for reliable assessment? Test duration depends on application requirements. Programs range from 100-1000 cycles for commercial applications, with extended testing to 10,000 cycles for high-reliability applications. Statistical analysis guides optimization balancing effectiveness against duration.

What failure mechanisms does thermal cycling identify? Testing identifies solder fatigue, via cracking, lead fatigue, delamination, and interface degradation. Protocols detect expansion mismatch effects, interconnection issues, and parameter drift enabling comprehensive assessment.

How do conditions relate to actual operating environments? Properly designed testing provides excellent correlation when temperature ranges and cycling rates align with actual profiles. Acceleration factors enable lifetime prediction based on amplitude and frequency relationships through Coffin-Manson modeling.

What parameters should be controlled during testing? Critical parameters include temperature uniformity within ±2°C, humidity control preventing condensation, vibration isolation, and EMI shielding. Precise control ensures consistent acceleration and prevents artificial failures.

Can testing predict reliability in different climates? Comprehensive testing provides reliable prediction when conditions encompass expected field ranges. Climate-specific protocols address regional variations and environmental interactions enabling accurate prediction for diverse deployments.