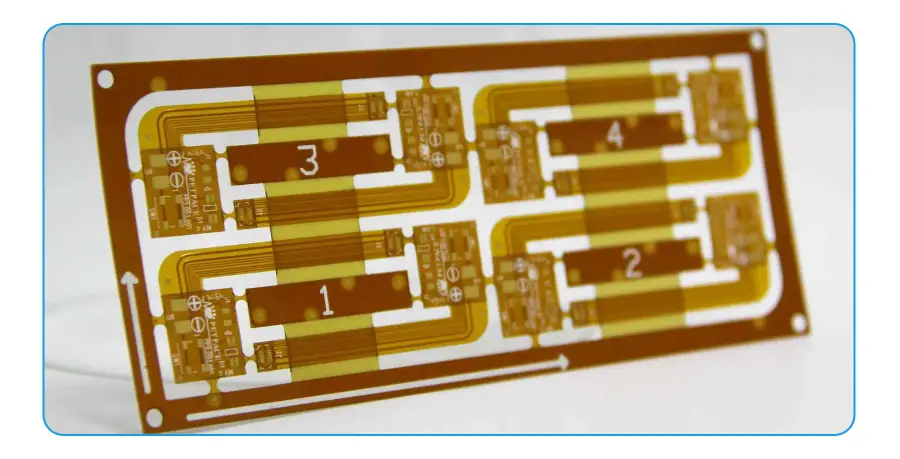

Ultra-thin PCBs enable miniaturized electronics to function within compact enclosures while maintaining full electrical performance. At Highleap PCB Factory, we manufacture and assemble custom ultra-thin PCBs using specialized materials and controlled processes to meet extreme dimensional and routing demands.

We support R&D teams building high-density flex circuits, paper-thin sensors, camera modules, and wearable electronics—any application where thickness, bend radius, and pad reliability are critical.

Highleap’s ultra-thin PCB capabilities often complement flex PCB technologies, especially in wearables and foldable displays. For projects needing more structural rigidity in minimal thickness, our FR4-based thin PCB options allow tight mechanical tolerances without sacrificing thermal performance.

All of this is supported by our advanced PCB manufacturing infrastructure, calibrated for tight copper distribution and multi-pass lamination of specialty materials.

Ultra-Thin Stack-Ups, Substrates, and Use Cases

Highleap supports advanced lamination and copper balancing techniques to deliver consistent quality on ultra-thin builds. We routinely fabricate:

- 0.1 mm to 0.3 mm finished board thicknesses

- Polyimide-based and ultra-thin FR4 cores

- Single- and double-layer flexible formats

- High-precision panel handling to avoid warpage

- Bend-tested circuits for dynamic movement zones

We also provide hybrid thin-rigid-flex constructions for module integration in mobile electronics and optical sensors. These designs often benefit from rigid-flex PCB structures that allow both stability and flexibility in constrained enclosures.

Here’s a condensed summary of supported configurations:

| Spec Feature | Capability |

|---|---|

| Min Thickness | 0.10 mm (single-layer) |

| Base Material | FR4 0.05 mm, PI 0.025 mm |

| Surface Finish | ENIG, OSP, Imm Silver |

| Target Markets | Wearables, camera modules, smartcards, flexible tags |

| Support Services | Panel design, stiffener bonding, semi-auto lamination |

Considerations for Ultra-Thin PCB Routing and Assembly

Routing thin boards requires process calibration and correct stack-up preparation. Unlike standard PCBs, ultra-thin PCBs:

- Require precision solder mask alignment and reduced thermal profiles

- Are vulnerable to flex cracking, requiring gentle bend radii

- May need added carrier frames or temporary rigidization during assembly

At Highleap, our SMT line supports low-pressure placement and temperature profiling for delicate ultra-thin boards. Our team also helps validate the appropriate copper weight, plating thickness, and surface finish depending on your final assembly method—especially when automated handling is involved.

Our in-house tooling allows for tight panelization control, and we support tooling holes, fiducials, or peelable stiffeners to aid in downstream processing and test.

Conclusion

Ultra-thin circuit boards are no longer a niche—they’re a vital part of today’s embedded and wearable designs. As an experienced ultra-thin PCB manufacturer and assembly provider, Highleap PCB Factory delivers tight-tolerance, quick-turn results with full engineering collaboration.

We offer short lead times, fast quoting, and post-sales support for complex, space-constrained builds that demand stability and yield. With secure order handling, traceable materials, and global fulfillment options, we simplify the supply chain for teams needing dependable thin PCB partners.