At Highleap PCB Factory (HILPCB), we specialize in manufacturing waterproof PCBs engineered to withstand challenging environmental conditions. Our comprehensive moisture protection solutions combine advanced materials, specialized coatings, and proven assembly techniques to deliver circuit boards that perform reliably in marine, outdoor, automotive, and industrial applications.

Advanced Waterproofing Technologies and Material Selection

Critical Moisture Barriers at the Molecular Level

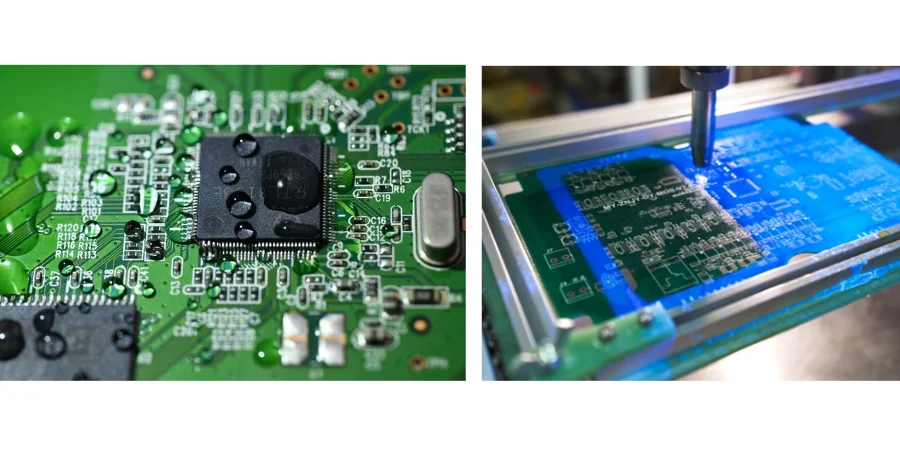

Waterproof PCB performance fundamentally depends on preventing moisture penetration at three critical interfaces: the substrate-copper boundary, via barrel walls, and component-solder joints. Our advanced waterproofing approach targets each vulnerability with specific solutions:

- Substrate Engineering: Beyond standard FR-4 PCB materials, we employ hydrophobic resin systems with siloxane modifications that reduce moisture absorption to <0.05%. Critical applications utilize PTFE-ceramic composites achieving moisture absorption below 0.01%

- Via Protection Systems: Resin-filled vias using specialized epoxy formulations with glass transition temperatures exceeding 150°C prevent thermal pumping that drives moisture ingress

- Edge Sealing Technology: Proprietary polyurethane edge sealants with 300% elongation accommodate thermal expansion while maintaining hermetic barriers

Surface Chemistry Optimization

The copper-coating interface represents the highest failure risk in waterproof PCBs. Our plasma-enhanced surface modification creates hydroxyl-rich surfaces with contact angles below 10°, ensuring complete coating wetting. Silane coupling agents form covalent bonds between inorganic substrates and organic coatings, creating moisture-impermeable interfaces that survive 1000+ hours of pressure cooker testing at 121°C/100% RH.

Conformal Coating and Potting Technologies

Coating Selection Matrix for Optimal Protection

| Environment | Primary Coating | Thickness | Key Advantage |

|---|---|---|---|

| Marine/Saltwater | Parylene C + Urethane topcoat | 25μm + 75μm | Chemical barrier + mechanical protection |

| High Temperature | Silicone (MIL-I-46058C) | 100-150μm | Flexibility at -65°C to +200°C |

| Chemical Exposure | Fluorinated urethane | 50-100μm | Resists acids, bases, solvents |

| High Humidity | Acrylic + nano-ceramic | 75-125μm | Moisture barrier with heat dissipation |

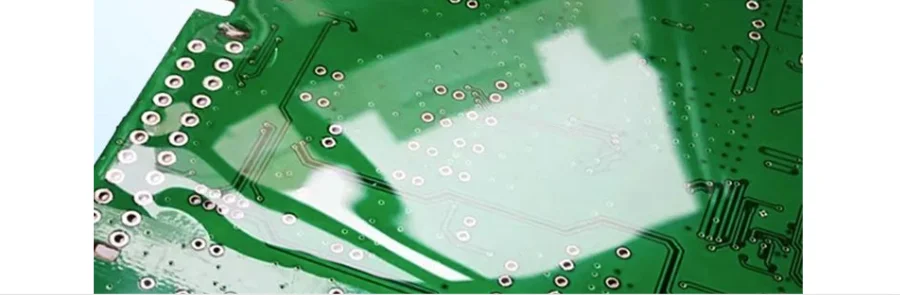

Advanced Application Techniques

Our selective coating process utilizes programmable 3-axis robots with ultrasonic spray heads, achieving coating uniformity within ±10μm. Real-time thickness monitoring using confocal sensors ensures complete coverage while preventing excess buildup. For complex geometries, we employ:

- Vapor deposition for uniform parylene application in high-aspect-ratio features

- Vacuum potting to eliminate voids in encapsulated assemblies

- UV-mapped curing that adjusts exposure based on coating thickness variations

Manufacturing Process Excellence for Waterproof PCBs

Process Control Points for Maximum Protection

- Moisture Preconditioning: Boards undergo 24-hour baking at 125°C followed by vacuum storage at <5% RH

- Surface Activation: Atmospheric plasma treatment increases surface energy to >72 dynes/cm

- Coating Application: Temperature-controlled spray booths maintain 23°C ±1°C, 45% ±5% RH

- Curing Optimization: Multi-stage profiles with controlled ramp rates prevent coating stress

- Quality Verification: 100% automated optical inspection using UV fluorescence

Statistical Process Control Metrics

- Coating thickness: Cpk >1.67

- Coverage completeness: >99.9%

- Adhesion strength: >7 N/cm (IPC-CC-830)

- Dielectric withstanding voltage: >1500V/mil

Our inline monitoring systems track 47 process parameters, enabling predictive quality control that identifies potential issues before they impact production.

Waterproof PCB Applications and Industry Solutions

Marine electronics demand the highest levels of moisture protection due to continuous saltwater exposure. Our marine PCB manufacturing incorporates specialized materials and coatings validated through extensive salt fog testing. Navigation systems, fish finders, and deck equipment benefit from our IP68-rated assemblies that withstand complete immersion. Specialized connector sealing and cable entry protection ensure system-level waterproofing for harsh marine environments.

Outdoor telecommunications equipment, including 5G base stations and IoT sensors, requires reliable moisture-resistant PCB solutions to maintain uptime. Our waterproof circuit boards for telecom applications feature enhanced lightning protection, UV-stable coatings, and thermal management solutions. Remote monitoring equipment in agricultural and environmental applications leverages our expertise in low-power, long-life waterproof designs.

Automotive applications increasingly require waterproof PCBs for engine compartment electronics, exterior lighting, and electric vehicle battery management systems. Our automotive-grade waterproof solutions meet IATF 16949 quality standards while surviving temperature extremes from -40°C to +125°C with condensing humidity. Medical devices, particularly wearable and implantable electronics, benefit from our biocompatible coating options and hermetic sealing expertise.

Rapid Prototyping and Production Scaling

Time-to-market pressures demand fast turnaround without compromising protection quality. Our waterproof PCB prototyping service delivers coated boards within 5-7 days for standard configurations. Complex assemblies with potting or specialized coatings typically require 10-14 days including cure time. We maintain inventory of common coating materials to eliminate procurement delays while our engineering team provides rapid design feedback for optimizing moisture protection.

Production scaling leverages automated coating equipment capable of processing thousands of boards daily while maintaining consistent quality. Our batch tracking systems ensure complete traceability from bare board through final coating application. Statistical process control monitors coating thickness, cure parameters, and environmental conditions to maintain tight specifications across volume production. Monthly capacity exceeds 100,000 waterproof PCB assemblies across various protection levels, from single and double layer PCBs to complex multilayer PCB designs.

Design Guidelines and Engineering Support

Successful waterproof PCB design requires consideration of multiple factors beyond coating selection. Our engineering team provides comprehensive design guidelines addressing component selection for moisture environments, layout optimization for coating coverage, and mechanical design for enclosure integration. We recommend specific via structures, trace spacing, and solder mask designs that enhance moisture resistance while maintaining manufacturability.

Thermal management in waterproof designs presents unique challenges as coatings and potting compounds can impede heat dissipation. We offer thermal modeling services to predict junction temperatures and optimize copper distribution for heat spreading. Our applications engineers assist with material selection balancing protection requirements with thermal performance, ensuring reliable operation across specified temperature ranges. For applications requiring enhanced thermal performance, we can integrate metal core PCB technology with waterproof coatings.

Complete Waterproof PCB Assembly Services

Beyond bare board manufacturing, HILPCB provides turnkey assembly waterproof PCB services. Our moisture-sensitive component handling procedures prevent damage during storage and assembly. Selective coating application protects populated boards while maintaining connector and test point accessibility. In-line coating inspection ensures complete coverage before curing, preventing costly rework.

We offer various packaging options for waterproof assemblies including custom gaskets, sealed enclosures, and cable gland integration. Environmental testing capabilities validate complete assembly performance including thermal shock, vibration testing with moisture exposure, and extended humidity testing. Our box-build assembly services deliver fully integrated waterproof electronic systems ready for deployment.

Frequently Asked Questions

What IP rating can your waterproof PCBs achieve?

Our waterproof PCB solutions achieve ratings from IP54 (dust and splash protection) up to IP68 (continuous immersion). The achievable rating depends on coating selection, application method, and enclosure design. We work with customers to determine appropriate protection levels based on application requirements and cost targets.

How does conformal coating affect PCB rework and repair?

Acrylic and silicone coatings can be removed locally using solvents or mechanical methods for component replacement. Urethane and parylene coatings are more challenging to remove but provide superior protection. We offer rework services and can recommend coating selections that balance protection with serviceability requirements.

What is the typical lifespan of waterproof PCB coatings?

Properly applied conformal coatings typically last 5-10 years in moderate environments and 2-5 years in harsh conditions. Factors affecting lifespan include UV exposure, temperature cycling, chemical exposure, and mechanical stress. We provide accelerated testing data to predict coating performance in specific applications.

Can waterproof coatings be applied to flexible PCBs?

Yes, we apply flexible conformal coatings like silicone and specialized acrylics to flex and rigid-flex PCBs. These coatings maintain flexibility while providing moisture protection. Special attention to coating thickness and application technique ensures the coating doesn't crack during flexing.

What testing standards do you follow for waterproof PCBs?

We test according to IPC-CC-830 for conformal coating qualification, ASTM B117 for salt spray testing, and various automotive and military specifications. Custom testing protocols can be developed for specific application requirements. All testing includes detailed reporting and photographic documentation.

How much does waterproofing add to PCB assembly cost?

Basic conformal coating typically adds 10-20% to assembly cost, while potting or specialized coatings may add 30-50%. However, the investment in proper waterproofing often reduces field failures by 90% or more, providing significant total cost of ownership benefits. We provide detailed quotes comparing different protection options.

What design features should be avoided in waterproof PCBs?

Avoid sharp corners that cause coating buildup, closely spaced components that prevent coating penetration, and tall components that create coating shadows. Through-hole components should be minimized as they create potential moisture paths. Our design review service identifies potential issues before manufacturing.

Can you provide waterproof PCBs for extreme temperatures?

Yes, we offer solutions for -55°C to +150°C operation using specialized materials and coatings. High-temperature applications may require silicone or parylene coatings, while low-temperature applications need coatings that remain flexible. Material selection considers both moisture protection and thermal requirements.