In modern lighting and display systems, white FR4 PCB plays a critical role in maximizing luminous efficiency. By combining high-reflectivity solder masks with advanced substrate engineering, white FR4 enables LED products to achieve greater brightness, lower heat generation, and longer operational life — without increasing power consumption.

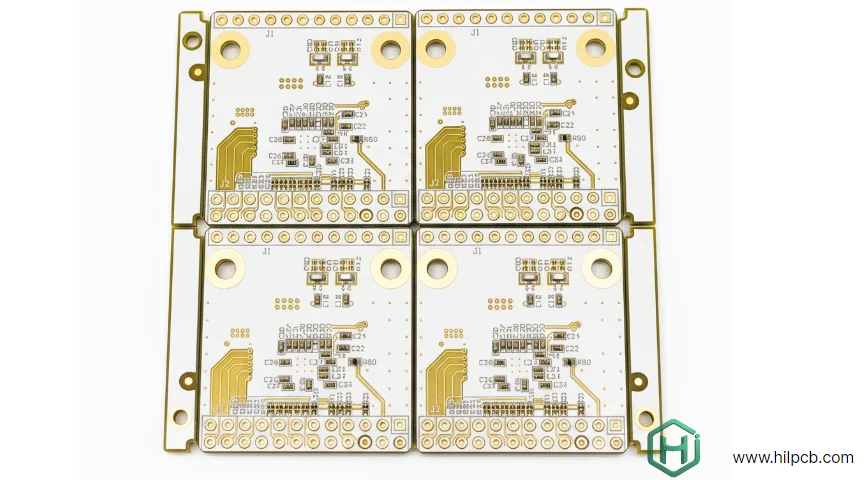

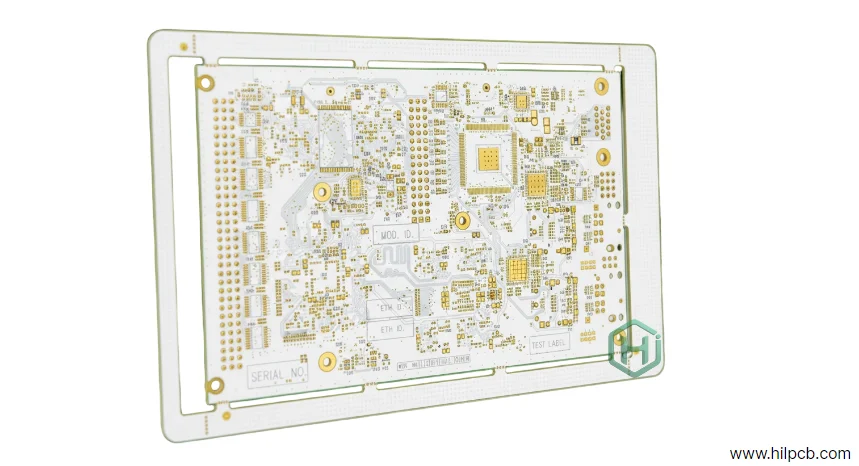

At HILPCB, we manufacture a wide range of PCB types, including FR4 PCB, high-Tg PCB, and metal-core PCB, optimized for optical performance, heat management, and precision assembly. Our white FR4 solutions are widely used in LED strips, display backlights, automotive lighting, and architectural illumination.

Optical Performance and LED Efficiency in White FR4 PCB Design

The optical behavior of a white PCB directly determines how efficiently light is reflected and distributed in LED assemblies. White solder masks are engineered with titanium dioxide (TiO₂) particles that diffuse light uniformly across the visible spectrum, enabling reflection rates of up to 92% — far higher than traditional green or black solder masks.

1. Reflectivity and Optical Stability

White FR4 PCBs utilize a Lambertian reflection pattern, scattering light evenly across the surface rather than reflecting it at narrow angles. This diffused reflection improves uniformity in LED backlight units (BLUs) and linear lighting systems, eliminating hot spots and color shading.

- Visible-spectrum reflectance: 400–700 nm wavelength coverage with <8% absorption

- UV resistance: Maintains >85% brightness after 1000 hours of UV exposure

- Color stability: Neutral CRI (Color Rendering Index) above 95 for accurate tone reproduction

Compared with standard multilayer PCB substrates, white FR4 delivers significantly better optical consistency under high-temperature operating conditions.

2. Material Composition and TiO₂ Engineering

The titanium dioxide filler concentration in the solder mask is critical for achieving stable reflectivity. Too little TiO₂ reduces brightness; too much can cause brittle coating and poor adhesion. At HILPCB, we optimize the TiO₂-to-resin ratio through process calibration to maintain an ideal balance of opacity, adhesion, and thermal stability.

Additionally, advanced formulations use low-absorption epoxy systems to reduce yellowing and preserve long-term brightness in LED lighting and signage. The result is a high-reflectivity PCB that performs reliably in both indoor and outdoor illumination systems.

3. Design Considerations for Maximum LED Output

Proper PCB layout and stack-up design are key to harnessing the full benefits of white FR4’s optical properties. Key design principles include:

- Copper pad optimization: Adjusting copper coverage around LED footprints to combine specular and diffuse reflection, increasing total light output by up to 10%.

- Via placement: Using filled via-in-pad designs prevents light leakage and maintains aesthetic uniformity.

- Edge treatment: Applying white routing or 45° chamfering along board edges minimizes absorption losses.

- Thermal control: Integration with high-thermal PCB layers ensures temperature stability without reducing brightness.

By combining optical and thermal optimization, HILPCB helps customers achieve both higher lumen efficiency and longer LED life in their final products.

Manufacturing Precision for White Solder Mask PCBs

Producing white FR4 PCBs requires greater process control than standard green or black finishes. The titanium dioxide pigments scatter UV light during photoimaging, demanding refined exposure and curing adjustments to ensure mask consistency and resolution clarity.

Key manufacturing parameters include:

- Exposure compensation: +50% UV intensity for accurate imaging through TiO₂ layers

- Mask thickness control: 25–30 μm uniformity for complete opacity

- Surface preparation: Ionic contamination <1.0 μg/cm² to avoid visible blemishes

- Finishing compatibility: Excellent adhesion with ENIG, OSP, and HASL finishes

Our advanced HDI PCB lines and SMT assembly facilities ensure fine-pitch LED mounting accuracy and high cosmetic consistency, essential for high-end lighting panels and display modules.

Applications of White FR4 PCB Technology

White FR4 PCBs are utilized in diverse LED-based and optical applications that require high brightness, low heat, and aesthetic surface quality.

- LED Backlight Panels: Used in displays, televisions, and signage with tight uniformity tolerance (<±2% reflectivity variation).

- Architectural Lighting: Ceiling and linear luminaires leveraging high reflectivity to improve energy efficiency.

- Automotive Lighting Systems: Dashboard and headlamp modules requiring durable, UV-stable coatings.

- Horticultural Lighting: Full-spectrum grow lights optimized for PAR efficiency (400–700 nm range).

For higher current or thermal demands, we integrate white FR4 layers with aluminum or copper substrates, similar to hybrid heavy-copper PCB or rigid-flex PCB structures — combining reflectivity with superior heat dissipation.

The Advantages of Choosing HILPCB for FR4 PCB Manufacturing and Assembly

At HILPCB, we manufacture FR4 PCBs in a variety of finishes and colors, including white FR4 when specified by customers. One of our key strengths lies in solder mask process control — our precisely managed coating and curing systems ensure uniform mask thickness, sharp pad definition, strong adhesion, and long-term color stability. These controls minimize rework, reduce soldering defects, and keep every board within both visual and electrical specifications, whether the focus is appearance consistency or performance reliability.

Because fabrication and assembly are performed under one roof, this same level of precision carries through to component placement, soldering, and testing. Our integrated PCB assembly process ensures that the solder mask quality you see during fabrication directly supports clean solder joints, consistent wetting, and stable performance in the finished product. The result is a reliable, production-ready FR4 PCB — built for efficiency, quality, and seamless assembly.