The rise of IoT and smart devices has made wireless connectivity a critical element in a wide range of industries. Whether you're developing Bluetooth, WiFi, Zigbee, LoRa, or other wireless devices, a reliable and high-performance PCB is essential. We specialize in custom wireless PCB manufacturing for a variety of applications, ensuring your devices meet performance and certification standards while maintaining cost efficiency.

We understand the complexities of designing wireless PCBs for IoT devices, wearables, smart home controllers, and more. Our PCB solutions are engineered to deliver seamless connectivity, durability, and energy efficiency.

What Is a Wireless PCB and How Does It Work?

A Wireless PCB integrates RF (radio frequency) circuitry with power management, digital processing, and application-specific sensors or controls. It is designed to handle wireless communication efficiently while operating in compact spaces with low power consumption.

Key Components of Wireless PCB

RF Front-End Circuitry: Responsible for signal transmission and reception.

- Transmit Path: Upconverts baseband signals to RF frequencies and amplifies them for antenna transmission.

- Receive Path: Boosts incoming RF signals through filters and low-noise amplifiers (LNAs), ensuring signal clarity.

- RF Switches: Share a single antenna for transmission and reception, often employing antenna diversity for signal optimization.

Our high-frequency PCB manufacturing process ensures optimal impedance control and minimal signal loss in these critical RF paths.

- Digital Processing: Wireless solutions integrate SoCs like ESP32, nRF52, or CC1352 that combine RF transceivers, processors, and peripherals on a single chip. These interfaces include SPI, I2C, GPIO, and ADC for communication, control, and sensing.

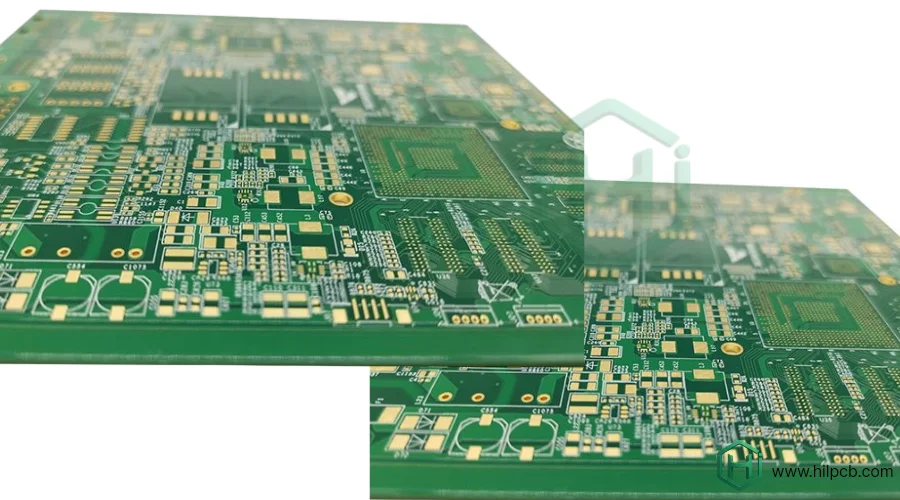

We employ multilayer PCB designs to ensure signal integrity and prevent noise from coupling into RF circuits.

- Power Management: Efficient power management is crucial in wireless IoT devices that rely on batteries. We use DC-DC converters and LDO regulators to ensure stable power delivery while minimizing noise. Additionally, our designs support sleep mode management and energy harvesting for long battery life.

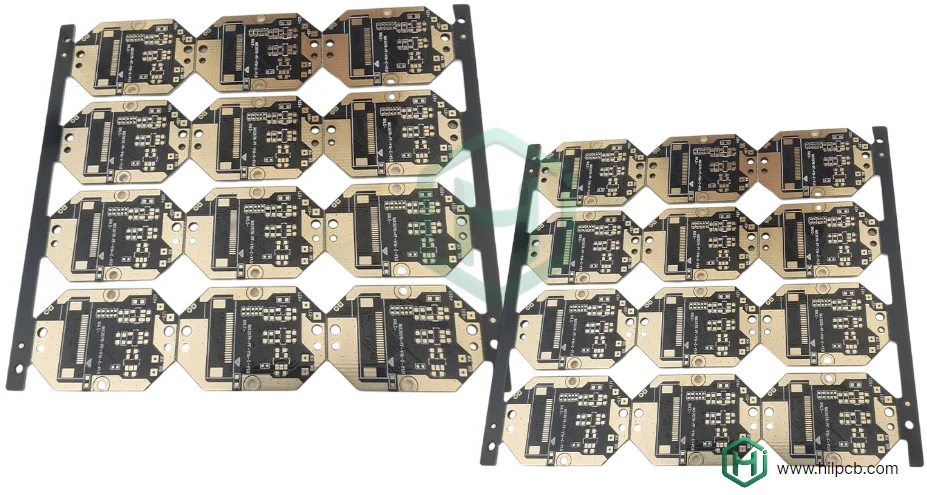

For wearable and space-constrained wireless devices, we utilize rigid-flex PCB technology.

Antenna Integration for Wireless PCBs

The antenna design is integral to the performance of wireless devices. Our PCB designs support various types of antennas:

- PCB Trace Antennas: Compact and cost-effective, they are ideal for 2.4 GHz, 5 GHz, and other frequency bands.

- Chip Antennas: These small, surface-mount antennas provide consistent performance in compact form factors.

- External Antennas: For applications requiring maximum range, we incorporate connectors like U.FL or SMA to attach external antennas.

We ensure optimal antenna placement and impedance matching to improve wireless range and signal quality.

Ensuring Signal Stability for Wireless PCBs

Signal stability is crucial for maintaining reliable wireless communication. Instabilities can cause bit errors, connection drops, or failed certification tests. Here's how we ensure stability:

- Crystal Oscillator Stability: We select crystals with low tolerance and minimize PCB layout issues like load capacitance and thermal gradients, ensuring stable oscillation.

- Phase Noise and Jitter Control: We design our layouts to minimize phase noise, ensuring receiver sensitivity and transmitter purity.

- Power Supply Noise Rejection: We use advanced filtering and decoupling techniques to prevent power supply noise from affecting the wireless signal.

Our high-speed PCB expertise ensures your wireless device delivers reliable communication in any environment.

Choosing Low-Loss Materials for Wireless PCBs

The material selection for wireless PCBs impacts performance and cost. We optimize the following aspects:

- Dielectric Loss: At RF frequencies, the material’s loss tangent determines how much signal energy is dissipated as heat. We use materials with low loss tangent, like Rogers and enhanced FR4, for critical RF paths.

- Copper Selection: We use reverse-treated foil for reduced loss at higher frequencies and ensure smooth copper surfaces to minimize the skin effect.

- Thermal Properties: Wireless power amplifiers generate heat, requiring thermal management materials like metal-core PCBs or high-thermal laminates to dissipate heat effectively.

For high-performance wireless applications, we select materials with low dielectric loss, high thermal conductivity, and optimal CTE (Coefficient of Thermal Expansion).

Optimizing Soldering and Assembly for Wireless PCBs

Wireless PCBs often feature fine-pitch components and sensitive RF traces. To ensure reliable assembly:

- Component Placement: We ensure that sensitive RF components are placed together, minimizing interconnection length and reducing loss.

- Thermal Management: Power amplifiers are placed near thermal vias to dissipate heat to the opposite side or internal planes.

- SMT Process Optimization: We ensure precision in placing fine-pitch components like BGAs and QFNs with SMT assembly and optimized reflow profiles to prevent component damage.

Testing Wireless PCBs for Communication Reliability

Our testing ensures that wireless PCBs meet performance standards before deployment:

- RF Parameter Testing: Using vector network analyzers, we measure return loss, insertion loss, and isolation to verify signal integrity.

- Functional Testing: We test the link range, data throughput, and packet error rates to ensure stable wireless communication.

- Regulatory Pre-Compliance: We perform conducted emissions and radiated emissions testing to meet FCC and CE standards.

We also offer turnkey assembly services to ensure your PCB is tested for reliability and compliance.

Fast and Reliable Wireless PCB Design, Manufacturing, and Assembly Services

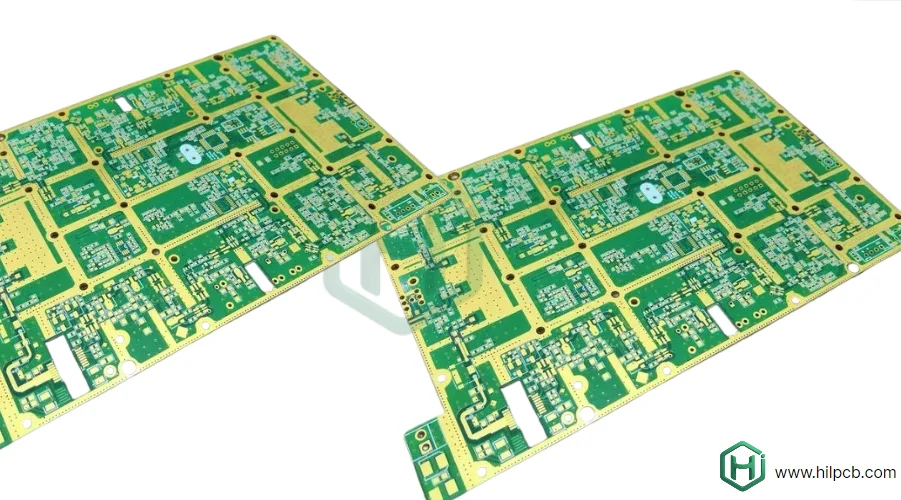

We offer comprehensive, fast-turnaround services for wireless PCB prototypes, covering design, manufacturing, and assembly to bring your wireless products to life efficiently and reliably.

Design, Manufacturing, and Assembly Timeline

- Design & Prototyping: 5-7 days for simple designs, 10-15 days for more complex multilayer boards. We work closely with you during the design phase to optimize for performance and manufacturability.

- PCB Manufacturing: Our robust manufacturing process ensures high-quality, reliable wireless PCBs. We use advanced materials and precise etching for minimal signal loss and excellent impedance control.

- Assembly & Testing: 3-5 days for assembly, followed by 2-3 days for thorough testing to ensure performance and regulatory compliance. We handle everything from SMT placement to turnkey assembly, offering complete solutions in one streamlined process.

One-Stop Solution

With our small-batch assembly services, we ensure that your prototypes are built, tested, and ready for market quickly, without compromising on quality.

Our end-to-end service supports you from initial design through final product validation, providing efficient, high-performance wireless PCBs for IoT devices, wearables, smart home products, and more.

Request Your Wireless PCB Quote today to get started with reliable, fast, and high-performance PCB manufacturing and assembly.