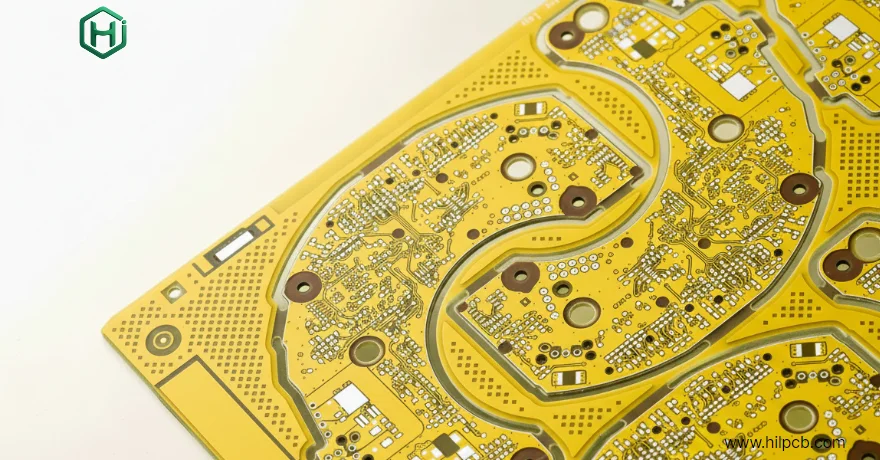

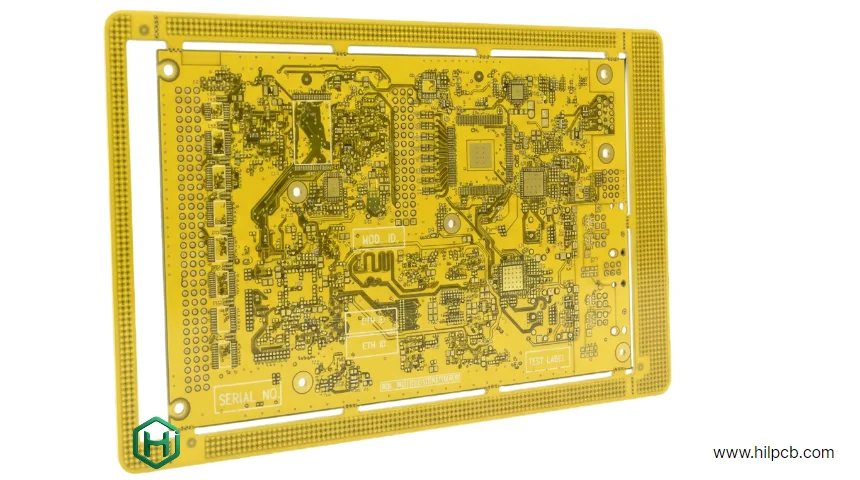

The yellow FR4 PCB combines standard FR4 substrate performance with a high-visibility yellow solder mask, delivering both functional and safety advantages. Unlike material upgrades such as high-Tg PCB or metal-core PCB, the yellow version focuses on visibility, inspection clarity, and ergonomic design — ideal for engineers who value both performance and usability.

At HILPCB, we manufacture yellow FR4 PCBs and also offer custom solder mask color options including red, blue, white, black, green, and fully personalized shades to match your brand or project needs. Our precision-engineered boards serve safety-critical, test, and measurement applications, ensuring color consistency, high reliability, and full compliance with IPC and CE standards.

Understanding Yellow FR4 PCB and Its Characteristics

The yellow solder mask is formulated with heat-stable organic pigments in epoxy resin, providing strong visual contrast without compromising mechanical or electrical performance.

Technical Properties of Yellow Solder Mask

- Reflectivity: 55–65% in the visible spectrum

- Color stability: ≤ ΔE 3 after 1,000 hours of UV exposure

- Adhesion strength: ≥ 1.5 N/mm (IPC-SM-840 Class T)

- Recommended thickness: 20–25 µm for full opacity

- Compatible finishes: ENIG, OSP, HASL, and immersion silver

Because yellow pigments are more light-transmissive, process control and UV calibration are essential for consistent tone and coverage.

Why Engineers Choose Yellow FR4 PCB

Yellow FR4 PCBs are not just visually striking — they improve productivity, safety, and clarity in real-world industrial applications.

1. Maximum Visibility and Safety Recognition

Human vision detects yellow faster than any color except white, making it ideal for safety systems and operator-critical devices:

- Emergency equipment: Fire alarms, gas detectors, and E-stop circuits use yellow for instant identification.

- Industrial safety modules: Yellow boards separate safety control circuits from standard ones, aligning with OSHA and CE marking requirements.

- Warning indicators: The yellow background enhances LED contrast and visibility across alert levels.

In demanding environments, this enhanced visibility can reduce operator response times by up to 30%.

2. Clarity and Efficiency in Test & Measurement

Yellow PCBs excel in engineering and quality-control scenarios:

- Probe visibility: Test points are 40% easier to locate.

- Version control: Test boards are easy to distinguish from production units.

- Wear tracking: Probe marks remain clearly visible for maintenance scheduling.

- Photography: Yellow PCBs photograph evenly across lighting conditions.

These benefits make yellow FR4 ideal for test fixtures, debugging, and calibration systems where precision matters.

Manufacturing Process of Yellow FR4 PCB

Producing yellow solder mask PCBs requires precise process control to maintain both color uniformity and material strength. At HILPCB, we apply dual-layer coating, UV monitoring, and color calibration to ensure every batch meets industrial standards.

1. Solder Mask Coating

- Surface preparation: Micro-etching improves adhesion.

- Application: Multi-pass coating ensures full coverage and opacity.

- Target thickness: 22 ± 3 µm to balance insulation and visual performance.

2. UV Exposure and Development

Because yellow transmits more light, exposure is controlled at 300–350 mJ/cm², maintaining consistent tone and fine pad definition. Development is optimized to avoid underexposure and preserve clarity.

3. Curing and Quality Control

Curing is performed in two stages — pre-bake at 90°C (10 min) and final bake at 150°C (30 min) — achieving mechanical hardness ≥ 5H and gloss level 20–40 GU. Color variation is kept within ±3 ΔE to ensure visual uniformity across production runs.

Color Selection Decision Matrix

| Application | Recommended Color | Reason |

|---|---|---|

| Safety systems | Yellow | Maximum visibility |

| High temperature | Black FR4 PCB | Better heat dissipation |

| LED lighting | White FR4 PCB | Reflectivity enhancement |

| Medical devices | Blue FR4 PCB | Professional, calm appearance |

| Prototypes | Red FR4 PCB | Version tracking |

| Cost-sensitive | Green FR4 PCB | Economical and common |

| Premium products | Premium FR4 PCB | High-end finish |

Design Recommendations

To achieve consistent performance and a clean visual finish, consider the following guidelines:

- Silkscreen color: Black offers the best contrast on yellow; white is acceptable for secondary markings.

- LED colors: Adjust LED selection — red appears slightly orange, green shifts warmer.

- Shade consistency: Specify Pantone 7405C (Safety Yellow) for repeatable production results.

- Mask clearance: Maintain ≥0.15 mm to avoid overexposure or bridging.

These recommendations ensure both functional clarity and professional aesthetics.

Cost Considerations

Yellow FR4 PCBs typically cost 12–18% more than standard green due to pigment formulation, opacity control, and smaller production batches. However, the added cost is justified when:

- Safety compliance reduces operational risk

- Improved visibility cuts human error by over 5%

- Maintenance and inspection time decreases by 10% or more

For OEMs and test engineers, yellow FR4 offers a measurable ROI through safety, accuracy, and reliability.

Why Choose HILPCB for PCB Manufacturing

HILPCB provides a complete range of PCB fabrication and turnkey assembly services, delivering high-performance boards for industrial, automotive, medical, and consumer sectors.

We produce all major PCB types — multilayer PCB, HDI PCB, metal-core PCB, and rigid-flex PCB — in every solder mask color including red, yellow, blue, green, white, black, and fully customized options.

Every board is made under strict DFM control, SPC color calibration, and IPC Class 3 reliability standards to ensure the highest quality and visual consistency.

Whether you’re designing for safety systems, testing equipment, or branding-specific applications, HILPCB ensures your PCB color, performance, and reliability meet professional standards.