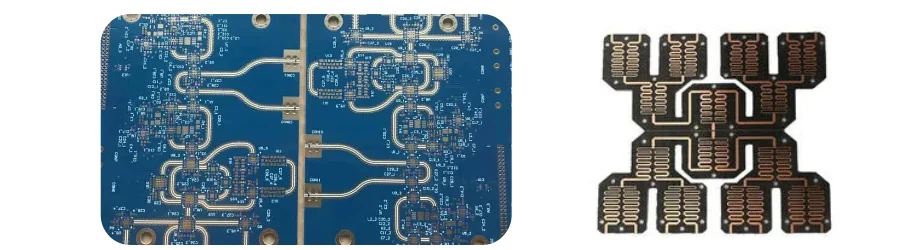

The global RF and microwave electronics market continues expanding rapidly, driven by 5G infrastructure, automotive radar, and IoT connectivity demands. At the heart of every high-performance RF system is the 50-ohm impedance PCB—a precision-engineered circuit board that ensures optimal signal transmission, minimal reflections, and maximum power transfer efficiency.

Our advanced 50-ohm impedance PCB manufacturing capabilities enable engineers to deliver cutting-edge RF products that meet stringent performance requirements while maintaining cost-effective production schedules. From cellular base stations to automotive radar systems, we provide the impedance precision that makes the difference between project success and failure.

Quality 50-Ohm PCB Manufacturing with Cost Control

Balancing premium RF performance with cost efficiency in 50-ohm impedance PCB manufacturing requires a systematic approach that integrates engineering precision, material optimization, and lean production management. In RF applications where impedance variations of just 2-3 ohms can degrade system performance, every design choice and process parameter directly influences both signal integrity and production cost.

1. Engineering for Manufacturability (DFM/DFA)

We begin with comprehensive Design for Manufacturability (DFM) review for 50-ohm applications. This includes optimizing trace width calculations for target impedance, selecting appropriate reference plane configurations, and standardizing via designs to match our automated SMT assembly capabilities. For RF circuits, we use electromagnetic simulation and pre-production impedance modeling to prevent costly design iterations. Early engineering collaboration typically reduces re-spin rates by over 35%, directly lowering development costs and time-to-market.

2. Strategic Material Selection and Sourcing

Substrate materials account for 35-45% of 50-ohm PCB manufacturing cost. We work with certified suppliers of high-frequency PCB laminates, low-loss FR4, and specialized RF materials to secure consistent quality at competitive pricing. For demanding applications, we utilize Rogers PCB materials including RO4003C and RT/duroid series. Strategic inventory management of common dielectric thicknesses and copper weights reduces lead times and mitigates raw material price fluctuations.

3. Process Optimization and Automation

Our controlled impedance drilling, precision etching, and automated assembly lines maintain trace width tolerances within ±0.5 mil and dielectric thickness variations under ±5%. Automated Optical Inspection (AOI), impedance testing, and comprehensive RF validation ensure 50-ohm accuracy. Statistical Process Control (SPC) monitors copper plating uniformity, etch factor consistency, and lamination quality in real-time—reducing scrap rates and rework costs that significantly impact high-frequency PCB profitability.

4. Panel Utilization and Yield Management

For RF designs, panel layout optimization maximizes production efficiency while maintaining signal integrity. Our CAD-based panelization algorithms optimize impedance test coupon placement and minimize cross-panel variations. Multi-product panels allow cost sharing across different RF projects, reducing tooling costs for prototype and low-volume production. Yield data analysis from previous 50-ohm productions feeds continuous improvement initiatives.

5. Quality Assurance with Performance Focus

Quality control extends beyond dimensional inspection to comprehensive RF performance validation. We conduct impedance verification using Time Domain Reflectometry (TDR), S-parameter measurements up to 40 GHz, and thermal cycling validation. For automotive and aerospace applications, we add environmental stress testing including thermal shock, humidity exposure, and mechanical stress validation. This performance-focused QA reduces field failures and warranty costs while building customer confidence.

By combining precision engineering, cost-conscious sourcing, and data-driven manufacturing control, we deliver high-quality 50-ohm impedance PCBs that meet demanding RF performance requirements while maintaining production economic viability.

Managing Signal Integrity in High-Frequency 50-Ohm PCB Design

In RF and microwave applications, signal integrity depends critically on maintaining consistent 50-ohm impedance throughout the signal path. Impedance variations, discontinuities, and losses can severely degrade system performance, causing signal reflections, increased insertion loss, and EMI problems that affect overall system reliability.

Key elements of our signal integrity approach for 50-ohm PCB include:

- Pre-layout electromagnetic simulation to optimize trace geometries and layer stackups

- Controlled dielectric selection with stable Dk and low loss tangent for frequency stability

- Precision copper plating to maintain consistent trace cross-sections

- Via transition optimization including back-drilling and controlled anti-pad design

- Reference plane management ensuring continuous ground planes for stable impedance

- Manufacturing process control to achieve ±3% impedance tolerance consistently

Through these measures, we ensure 50-ohm PCBs maintain optimal signal integrity across the target frequency range, reduce system-level EMI, and meet stringent RF performance specifications—helping brands deliver reliable products that perform consistently in demanding applications.

Accelerating Time-to-Market for RF Product Development

Speed as Competitive Advantage

In RF and microwave markets—especially 5G infrastructure and automotive radar—development cycles are compressed, and early market entry can determine product success. Design iteration delays can mean missing critical design-in opportunities or losing competitive positioning.

Integrated Development Workflow

Our streamlined 50-ohm PCB development process includes:

- Early Impedance Modeling — electromagnetic simulation and design optimization before prototyping

- Rapid Prototyping — producing functional 50-ohm test boards in 3-5 days

- RF Performance Validation — complete S-parameter testing and impedance verification

Reduced Development Risk

By providing both PCB fabrication and assembly expertise under one roof, we eliminate vendor coordination delays, ensure design intent preservation, and provide comprehensive RF test data. This integrated approach accelerates product development cycles without compromising 50-ohm performance.

Market Responsiveness

This development agility enables you to:

- Synchronize product launches with market windows

- Respond quickly to customer specification changes

- Iterate designs rapidly based on system-level testing

- Reduce overall development costs through faster convergence

Customization for Specialized RF Applications

50-ohm impedance requirements extend across diverse RF applications—from consumer wireless devices to military radar systems. Each application demands optimized PCB characteristics for frequency range, power handling, environmental conditions, and form factor constraints.

We support custom stackup designs, specialized material selection, and precision manufacturing for applications including millimeter-wave communications, automotive radar sensors, medical RF devices, and aerospace systems. For high-power applications, we integrate thermal management solutions and high thermal PCB materials. For ultra-low loss requirements, we employ advanced PTFE laminates and precision surface finishes.

Our engineering team provides impedance modeling, electromagnetic simulation, and design optimization to help customers achieve optimal 50-ohm performance for their specific application requirements. Whether developing next-generation 5G infrastructure or specialized test equipment, we deliver the precision and customization needed for RF success.

End-to-End Solutions for 50-Ohm PCB Success

Delivering competitive RF products requires more than precision PCB fabrication—it demands integrated engineering and manufacturing partnership covering concept through production. We provide comprehensive support including stackup optimization, material selection guidance, electromagnetic simulation validation, precision fabrication with controlled impedance, and complete turnkey assembly with RF testing.

Beyond core PCB manufacturing, we support complete RF system development including antenna integration, RF module assembly, shielding design, and test fixture development. Our capabilities extend to power management circuits, digital control boards, and system interconnects that complement your 50-ohm RF circuits.

By consolidating these capabilities, we eliminate multi-vendor complexity, reduce communication delays, and ensure consistent quality across all components. Our integrated workflow accelerates development cycles, enables rapid scaling from prototype to production with our small batch assembly to large volume assembly capabilities, and provides comprehensive documentation for regulatory compliance.

Whether developing cutting-edge 5G infrastructure, automotive radar systems, or specialized RF test equipment, our end-to-end approach ensures your 50-ohm PCB—and complete RF system—delivers optimal performance, reliability, and market competitiveness.