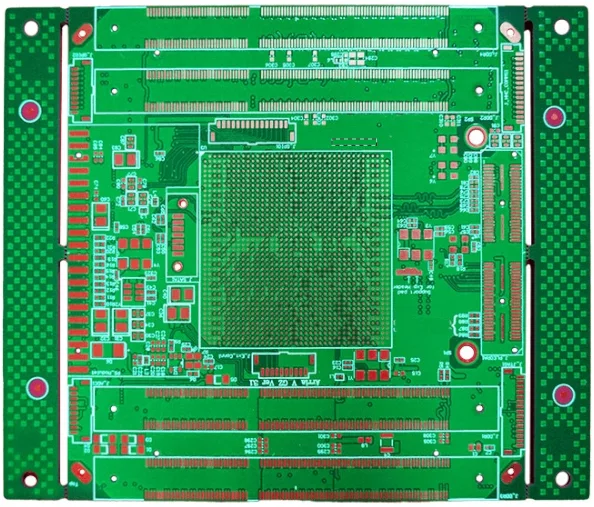

High-Density Interconnect (HDI) PCB technology represents the pinnacle of modern electronics manufacturing, enabling the creation of compact, high-performance devices that power today's smartphones, tablets, and advanced computing systems.

Understanding HDI Technology

HDI PCBs are characterized by their fine lines, small vias, and high connection pad density. These boards typically feature:

- Microvias: Holes with diameters ≤ 150μm

- Fine pitch components: BGA pitches down to 0.4mm

- Thin dielectric layers: 25-100μm thickness

- High layer counts: Up to 20+ layers in compact form factors

Manufacturing Process Overview

1. Sequential Lamination Process

The sequential build-up process is fundamental to HDI manufacturing:

Core Layer → Prepreg → Copper Foil → Lamination → Drilling → Plating

Each layer is built sequentially, allowing for precise control of impedance and signal integrity.

2. Micro-via Formation

Laser Drilling Technology

- CO2 lasers: For dielectric materials

- UV lasers: For copper removal

- Plasma desmear: Surface preparation for plating

Via Types in HDI

- Blind vias: Connect outer layer to inner layer

- Buried vias: Connect inner layers only

- Stacked vias: Multiple microvias in alignment

- Staggered vias: Offset microvias for routing flexibility

Advanced Quality Control

Automated Optical Inspection (AOI)

- High-resolution imaging systems

- Pattern recognition algorithms

- Defect classification and reporting

- Real-time process feedback

X-ray Inspection

- Via fill quality assessment

- Hidden defect detection

- Layer alignment verification

- Component placement validation

Electrical Testing

- In-Circuit Testing (ICT): Continuity and isolation

- Flying Probe Testing: Flexible test point access

- Boundary Scan: Digital circuit verification

Material Considerations

Substrate Materials

- Low-loss dielectrics: For high-frequency applications

- Thermally conductive materials: For heat dissipation

- Low CTE materials: Dimensional stability

Copper Foil Selection

- Ultra-thin copper: 9μm and 12μm foils

- Low-profile copper: Reduced surface roughness

- Treated copper: Enhanced adhesion properties

Design Guidelines for HDI

Via Design Rules

- Minimum via size: 100μm (4 mil)

- Via-to-via spacing: 150μm minimum

- Via-to-trace spacing: 75μm minimum

- Annular ring: 25μm minimum

Trace and Space Requirements

- Minimum trace width: 75μm (3 mil)

- Minimum spacing: 75μm (3 mil)

- Impedance tolerance: ±10%

Applications and Benefits

Consumer Electronics

- Smartphones and tablets

- Wearable devices

- Ultra-thin laptops

- Gaming consoles

Industrial Applications

- Medical devices

- Automotive electronics

- Aerospace systems

- IoT devices

Performance Advantages

- Size reduction: Up to 70% smaller than conventional PCBs

- Weight reduction: Lighter form factors

- Improved signal integrity: Shorter signal paths

- Enhanced thermal performance: Better heat dissipation

Manufacturing Challenges and Solutions

Challenge: Via Reliability

Solution: Optimized drilling parameters and advanced plating chemistry

Challenge: Layer Registration

Solution: High-precision lamination equipment with vision systems

Challenge: Yield Optimization

Solution: Statistical process control and real-time monitoring

Future Trends in HDI Technology

Emerging Technologies

- Any-layer HDI: Vias connecting any layer combination

- Embedded components: Passive components within PCB layers

- 3D printing integration: Additive manufacturing techniques

- Advanced materials: Liquid crystal polymers and ceramics

Industry 4.0 Integration

- IoT-enabled manufacturing equipment

- Predictive maintenance systems

- AI-driven quality control

- Digital twin technology

Quality Standards and Certifications

International Standards

- IPC-2226: HDI design guidelines

- IPC-6016: HDI qualification standards

- IPC-A-600: Acceptability criteria

- ISO 9001: Quality management systems

Testing Protocols

- Thermal cycling: -55°C to +125°C

- Humidity testing: 85°C/85% RH

- Mechanical stress testing

- Accelerated aging tests

Conclusion

Advanced HDI PCB manufacturing represents a critical capability for companies seeking to develop next-generation electronic products. The combination of precision manufacturing techniques, advanced materials, and rigorous quality control enables the creation of high-performance, reliable electronic assemblies.

At Highleap PCB, our investment in state-of-the-art HDI manufacturing equipment and processes ensures that we can meet the most demanding requirements for modern electronics applications.

For technical specifications and custom HDI solutions, contact our engineering team for a comprehensive consultation.