When the Suez Canal blockage halted global shipping in 2021, automated port systems worldwide felt the impact within hours. Container terminals from Rotterdam to Singapore relied on thousands of interconnected automation PCBs to coordinate cranes, guided vehicles, and inventory systems—all responding in real-time to supply chain disruptions through sophisticated control networks.

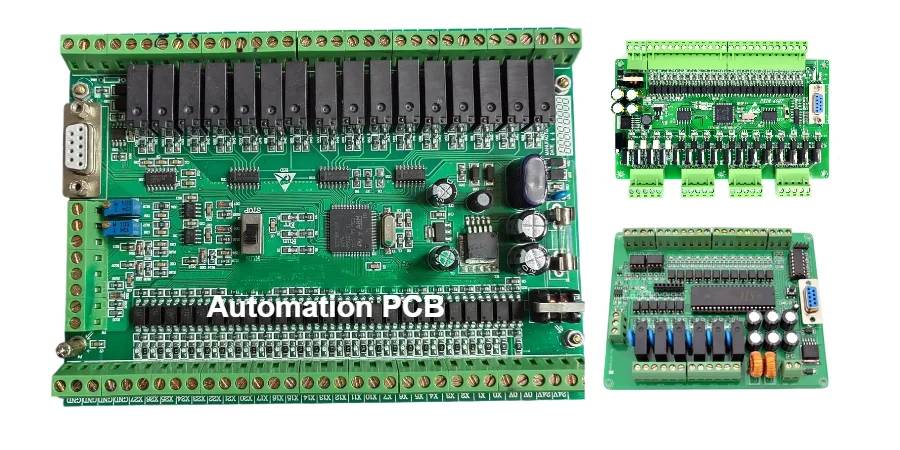

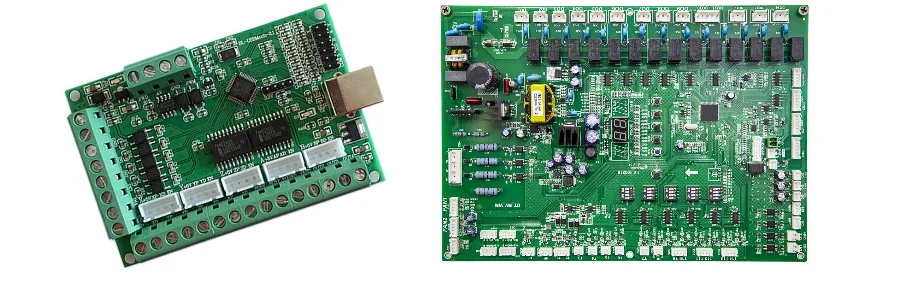

This scenario illustrates the invisible complexity of modern industrial automation, where PCBs function not as isolated components but as integrated nodes in vast control networks. At Highleap PCB Factory (HILPCB), we design automation PCBs that form the foundation of Industry 4.0 systems, enabling factories, power plants, and infrastructure to operate with unprecedented efficiency and reliability.

Industrial automation PCBs must seamlessly integrate process control, data acquisition, network communication, and safety systems while maintaining operation 24/7 for decades. Success requires understanding not just individual PCB requirements, but how these boards interact within complex automated ecosystems.

Factory Automation Control Networks

Modern manufacturing facilities operate as integrated systems where automation PCBs coordinate everything from raw material handling to finished product shipping, requiring designs that support real-time communication and distributed control architectures.

Production Line Coordination: Assembly lines use interconnected automation PCBs that synchronize conveyor speeds, robotic operations, and quality inspection systems. Each PCB functions as a node in a deterministic control network, maintaining precise timing relationships that prevent bottlenecks and maximize throughput. Backplane PCB architectures enable modular system expansion as production requirements evolve.

Material Handling Integration: Automated warehouses and material handling systems require PCB designs that coordinate complex logistics operations. RFID readers, barcode scanners, and positioning sensors provide inventory tracking while automated guided vehicles (AGVs) follow coordination signals from centralized control systems. Network protocols like EtherCAT enable microsecond-level coordination between distributed control nodes.

Quality Control Automation: Inline inspection systems use automation PCBs that integrate machine vision, precision measurement, and reject handling systems. High-speed image processing requires substantial computational power while maintaining real-time response to production line speeds. Data logging capabilities track quality trends and enable predictive maintenance scheduling.

Energy Management Systems: Smart factories monitor and optimize energy consumption through distributed automation PCBs that track power usage, demand response, and renewable energy integration. Power monitoring circuits measure consumption at individual machine levels while communication interfaces report data to enterprise energy management systems.

Maintenance and Diagnostics: Predictive maintenance systems use automation PCBs with integrated vibration sensors, temperature monitoring, and current signature analysis to predict equipment failures before they occur. Machine learning algorithms running on edge computing platforms analyze sensor data to identify patterns indicating impending failures.

Process Control and SCADA Integration

Process industries rely on automation PCBs that monitor and control continuous operations, requiring exceptional reliability and integration with supervisory control and data acquisition (SCADA) systems for plant-wide coordination.

Chemical Process Control: Chemical manufacturing uses automation PCBs that manage reactor temperatures, pressure control, and material feed rates with precision measured in parts per million. Explosion-proof enclosures and intrinsically safe circuits ensure operation in hazardous environments while maintaining process control accuracy. Safety instrumented systems provide independent protection against dangerous process conditions.

Power Plant Automation: Electrical power generation requires automation PCBs that coordinate boiler controls, turbine governors, and grid synchronization systems. Generator protection circuits must respond to fault conditions within milliseconds while data acquisition systems log operational parameters for regulatory compliance and efficiency optimization.

Water Treatment Systems: Municipal water treatment facilities use automation PCBs that manage chemical dosing, filtration systems, and distribution pumps. Remote monitoring capabilities enable centralized control of geographically distributed facilities while local control systems maintain operation during communication outages.

Oil and Gas Operations: Petroleum facilities require automation PCBs designed for harsh environments with temperature extremes, corrosive atmospheres, and potential explosive conditions. Specialized materials and protective coatings ensure reliable operation while redundant communication systems maintain connectivity across vast industrial complexes.

Food and Pharmaceutical Manufacturing: Regulated industries demand automation PCBs with validated designs and complete documentation traceability. Clean room compatibility and wash-down capability accommodate strict hygiene requirements while batch recording systems maintain regulatory compliance for product lot tracking.

Building and Infrastructure Automation

Commercial buildings and critical infrastructure rely on automation PCBs that manage energy systems, security, and environmental controls while integrating with smart city initiatives and grid modernization programs.

HVAC System Integration: Modern buildings use automation PCBs that coordinate heating, ventilation, and air conditioning systems for optimal energy efficiency and occupant comfort. Variable air volume controls, chiller optimization, and thermal energy storage systems require sophisticated control algorithms and extensive sensor integration.

Lighting Control Networks: Smart lighting systems use automation PCBs that manage LED fixtures, occupancy detection, and daylight harvesting for maximum energy savings. Wireless mesh networking enables flexible installation while centralized control systems optimize lighting schedules based on occupancy patterns and energy costs.

Access Control and Security: Building security systems integrate automation PCBs that coordinate card readers, biometric scanners, and surveillance cameras with central monitoring systems. Real-time database synchronization ensures consistent access permissions across multiple facilities while audit trails maintain security compliance.

Fire Safety and Life Protection: Fire alarm and suppression systems require automation PCBs with life safety certification and redundant communication paths. Smoke detection, sprinkler control, and emergency notification systems must maintain operation even during power outages or communication failures.

Energy Storage and Grid Integration: Commercial buildings increasingly incorporate battery storage and renewable energy systems that require automation PCBs with grid-tie inverters, energy management algorithms, and utility communication interfaces. Peak shaving and demand response capabilities reduce energy costs while providing grid stability services.

Transportation Infrastructure Networks

Transportation systems depend on automation PCBs that coordinate traffic flow, monitor infrastructure health, and manage complex logistics operations across highways, railways, and airports.

Traffic Management Systems: Intelligent transportation systems use automation PCBs that control traffic signals, monitor congestion, and coordinate with connected vehicles. Real-time optimization algorithms adjust signal timing based on traffic patterns while emergency preemption capabilities ensure first responder access.

Railway Control Systems: Modern railways require automation PCBs that manage train positioning, signal control, and switch operation with safety integrity levels appropriate for life-critical applications. Positive train control systems prevent collisions and overspeeding while maintaining efficient operations across complex rail networks.

Airport Operations: Aviation facilities use automation PCBs that coordinate runway lighting, baggage handling, and ground support equipment. Integration with air traffic control systems and weather monitoring ensures safe operations while optimizing gate assignments and ground traffic flow.

Toll and Revenue Collection: Electronic toll collection systems rely on automation PCBs that integrate RFID readers, license plate recognition, and payment processing systems. High-speed vehicle identification must function reliably at highway speeds while maintaining transaction accuracy and system security.

Infrastructure Monitoring: Bridge health monitoring, tunnel ventilation, and roadway condition assessment use automation PCBs with integrated sensor arrays and wireless communication capabilities. Remote monitoring systems alert maintenance crews to potential issues while historical data enables predictive maintenance scheduling.

Industrial Safety and Emergency Response

Safety systems in industrial automation require specialized PCB designs that maintain operation under emergency conditions while providing protection for personnel and equipment.

Emergency Shutdown Systems: Process industries use safety instrumented systems (SIS) based on automation PCBs that provide independent protection against hazardous conditions. Triple modular redundancy and diagnostic coverage ensure reliable operation while meeting international safety standards like IEC 61508 and IEC 61511.

Fire and Gas Detection: Hazardous industries require automation PCBs that integrate gas detectors, flame sensors, and suppression systems with central monitoring and control. Voting logic and fault tolerance ensure reliable detection while minimizing false alarms that could disrupt operations.

Personnel Safety Systems: Access control and permit-to-work systems use automation PCBs that track personnel locations and ensure proper safety procedures before equipment startup. Integration with emergency response systems enables rapid personnel accounting during evacuation procedures.

Environmental Monitoring: Continuous emissions monitoring systems (CEMS) require automation PCBs that interface with analytical instruments and regulatory reporting systems. High-Tg PCB materials ensure reliable operation in high-temperature environments while maintaining measurement accuracy and regulatory compliance.

Crisis Communication: Emergency notification systems use automation PCBs that coordinate public address systems, digital signage, and mobile alerts during crisis situations. Redundant communication paths and backup power systems ensure message delivery even during infrastructure failures.

Frequently Asked Questions

Q: What makes automation PCBs different from standard industrial PCBs? Automation PCBs emphasize network integration, real-time communication, and system-level coordination. They require robust communication interfaces, deterministic timing, and integration with industrial protocols like EtherCAT, PROFINET, and Modbus.

Q: How do you ensure reliability in mission-critical automation systems? Use redundant designs, comprehensive environmental testing, industrial-grade components, and systematic quality management. Safety-critical applications require functional safety certification per IEC 61508/61511 standards.

Q: What communication protocols are most important for automation PCBs? Ethernet-based protocols (EtherCAT, PROFINET, EtherNet/IP) dominate new installations. Traditional fieldbus (PROFIBUS, DeviceNet) remains important for legacy integration. OPC-UA provides standardized data exchange between different systems.

Q: How do automation PCBs handle cybersecurity requirements? Implement hardware-based security features, encrypted communication, secure boot processes, and network segmentation. Regular security updates and vulnerability management become critical for connected industrial systems.

Q: What environmental testing is required for automation PCBs? Industrial automation PCBs must withstand temperature cycling, humidity, vibration, and electromagnetic interference per IEC 60068 standards. Specific applications may require additional testing for chemical resistance, explosion-proof certification, or radiation tolerance.