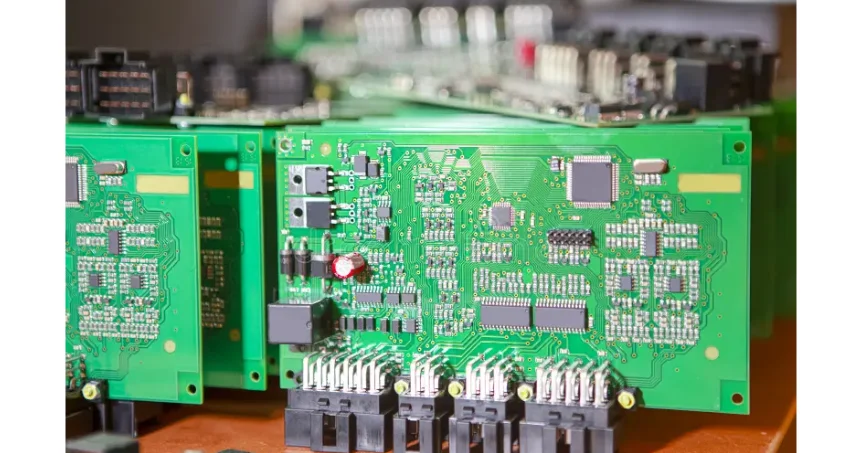

The automotive industry is experiencing one of its most transformative phases, driven by the increasing adoption of electric vehicles (EVs) and the rapid evolution of autonomous driving technologies. As the heart of modern vehicle electronics, automotive PCBs (Printed Circuit Boards) are playing a critical role in this transformation. Automotive PCB technology is evolving rapidly, supporting everything from electric powertrains to advanced driver-assistance systems (ADAS). As we move toward smarter and greener vehicles, the demand for high-performance automotive PCBs is higher than ever.

At Highleap PCB, we understand that as vehicles become more sophisticated, so too must the PCBs that power them. We provide automotive PCB manufacturing and assembly services tailored for next-generation vehicles. This article explores how automotive PCBs are enabling the transition to electric and autonomous vehicles and the vital role they play in the surrounding systems of modern vehicles.

Automotive PCBs in Electric Vehicles: Powering the Future of Transportation

Electric vehicles (EVs) are reshaping the automotive landscape, and automotive PCBs are essential for the operation of EVs. One of the most important aspects of EVs is their battery management systems (BMS), which control charging, discharging, and the overall health of the battery. Automotive PCBs within these systems ensure that the battery operates safely and efficiently, maximizing the vehicle’s performance.

Moreover, automotive PCBs are integral in the power inverters of electric vehicles. The inverters convert DC (Direct Current) power from the battery into AC (Alternating Current) power that drives the electric motor. These systems require highly reliable and durable automotive PCBs that can withstand high currents, temperature fluctuations, and vibrations — all of which are common in EV environments.

The rising popularity of EVs also means that automotive PCBs are becoming crucial components in the development of electric powertrains, which include systems such as motor controllers, chargers, and power converters. PCBs for electric vehicles need to be designed with high-density circuits and advanced thermal management capabilities, ensuring the vehicle’s powertrain operates seamlessly.

Automotive PCBs in Autonomous Vehicle Technologies

Autonomous vehicles (AVs) are the next frontier in automotive technology, relying heavily on electronic systems to navigate and make split-second decisions. Automotive PCBs are central to these systems, supporting radar, lidar, and sensor modules that enable real-time object detection and navigation. These systems require precise and fast signal processing, which is made possible by specialized automotive PCBs.

For example, the PCBs for autonomous vehicle radar systems must operate at high frequencies to accurately detect obstacles, while automotive PCBs used in sensor fusion must combine data from multiple sensors to create a cohesive view of the vehicle’s environment. These PCBs need to meet stringent reliability standards, as any failure could lead to catastrophic consequences. When working with high-speed signals or millimeter-wave radar designs, engineers can benefit from early simulation using tools like our impedance calculator to ensure proper impedance matching and signal integrity.

Additionally, autonomous driving PCBs must manage vast amounts of data from cameras, lidar, and other sensors. These systems are powered by high-speed automotive PCBs designed to maintain signal integrity and reduce the possibility of interference.

Automotive PCBs in Infotainment and Connectivity

The integration of advanced infotainment systems and in-vehicle connectivity has become a standard feature in modern vehicles. From infotainment PCBs that power multimedia systems to PCBs for connectivity modules that enable Bluetooth, Wi-Fi, and 5G communication, these boards are essential in enhancing the driver and passenger experience.

As vehicles become more connected, the role of automotive PCBs in managing vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication becomes even more critical. This interconnectivity supports advancements like autonomous driving, traffic management, and in-car entertainment that relies on real-time data transmission.

Automotive PCBs for infotainment systems need to provide high-speed data processing and integrate with cloud services, offering seamless navigation, streaming, and communication. As more features are integrated into vehicle systems, the complexity of automotive PCB designs will continue to grow, requiring more advanced capabilities to handle everything from multimedia processing to security. You can also use our Gerber Viewer to validate your PCB layout before prototyping or production.

PCB Designs for Vehicle Surrounding Systems: A Growing Trend

Modern vehicles are not only about the primary internal systems but also the surrounding systems that ensure overall safety and comfort. From automotive PCBs for lighting systems to PCBs for parking sensors, these supporting systems are increasingly reliant on advanced automotive PCB designs.

For instance, automotive PCBs for lighting systems power features like adaptive headlights, taillights, and interior lighting. These systems require PCBs that are resistant to extreme temperatures and vibrations, ensuring long-lasting performance and safety. Similarly, PCBs for parking sensors enable the detection of obstacles around the vehicle, providing essential assistance for drivers, especially in tight spaces.

As the automotive industry pushes toward smarter and more autonomous vehicles, automotive PCBs for vehicle surroundings will continue to be an essential aspect of the driving experience, ensuring that features like collision detection, automated parking, and 360-degree visibility are possible.

The Demand for High-Quality Automotive PCBs

With the evolution of the automotive industry, the demand for high-quality, high-performance automotive PCBs has skyrocketed. These boards must be designed to handle high temperatures, vibrations, and harsh environmental conditions while ensuring reliability and efficiency. Whether it's for electric vehicle powertrains, autonomous driving systems, or advanced infotainment, the PCB technology must meet strict industry standards to ensure vehicle safety, durability, and performance.

Moreover, automotive PCBs must comply with various safety regulations, such as ISO 26262, which ensures the functional safety of electronic systems in vehicles. Manufacturers must also adhere to environmental regulations, ensuring that the PCBs are produced using sustainable processes and materials that do not harm the environment.

Innovations in Automotive PCB Manufacturing

As the automotive industry continues to innovate, so too must the PCB manufacturing process. The demand for smaller, more efficient, and highly integrated automotive PCBs is driving innovations in PCB design, materials, and manufacturing techniques. For example, new technologies like flexible PCBs are being used in automotive applications where traditional rigid PCBs are not suitable, such as in compact or curved spaces.

Additionally, automotive PCBs for electric vehicles are increasingly being manufactured using advanced materials, such as high-frequency laminates and thermal management materials, to handle the demands of high-power systems. As electric and autonomous vehicles require more sophisticated electronics, PCBs will need to evolve to meet these new challenges, ensuring safety, efficiency, and performance.

Conclusion

Automotive PCBs are at the heart of the innovations shaping the future of the automotive industry. From electric vehicle systems and autonomous driving technologies to infotainment and vehicle surrounding systems, these boards are essential for ensuring the functionality, safety, and reliability of modern vehicles.

At Highleap PCB, we are committed to providing cutting-edge automotive PCB manufacturing and assembly services that meet the growing demands of the automotive industry. As the shift toward electric and autonomous vehicles continues, we are proud to be a part of the movement that drives innovation in vehicle electronics, supporting the development of smarter, safer, and more sustainable transportation solutions.