!The evolution of electronic devices toward miniaturization and increased functionality has driven significant advancements in printed circuit board (PCB) technology. Among these innovations, blind via PCB technology stands as a critical solution for achieving high-density interconnections in compact designs. This comprehensive guide explores the technical aspects, manufacturing processes, and applications of blind via PCB technology.

Understanding Blind Via PCB Technology

Blind via PCB technology represents a sophisticated approach to creating vertical connections within multilayer circuit boards. Unlike traditional through-hole vias that extend completely through all layers of a PCB, blind vias establish connections between specific layers without penetrating the entire board thickness. This selective connectivity enables engineers to optimize space utilization while maintaining signal integrity in complex electronic designs.

The fundamental principle behind blind via PCB construction involves creating precisely controlled holes that connect outer layers to inner layers, or inner layers to other inner layers, without compromising the structural integrity of uninvolved layers. This selective drilling approach allows for more efficient use of available board real estate, particularly crucial in applications where space constraints are paramount.

Modern blind via PCB manufacturing employs advanced drilling techniques, including laser drilling and mechanical drilling, depending on the specific requirements of the application. The choice of drilling method directly impacts the achievable via diameter, aspect ratio, and overall manufacturing precision.

📞 Have a question or need a blind via design reviewed?

Reach out to our technical team for expert guidance and cost-saving strategies.

Manufacturing Process and Technical Specifications

The production of blind via PCB requires specialized equipment and precise process control to achieve the necessary dimensional accuracy and reliability. The manufacturing sequence typically begins with the preparation of inner layer cores, followed by the selective drilling of blind vias at predetermined locations.

Laser drilling technology has emerged as the preferred method for creating micro-vias in blind via PCB applications. This technique enables the creation of extremely small diameter holes, typically ranging from 50 to 200 micrometers, with exceptional precision and minimal thermal impact on surrounding materials. The laser drilling process utilizes focused CO2 or UV laser beams to vaporize the PCB substrate material, creating clean, precise holes without the mechanical stress associated with traditional drilling methods.

The aspect ratio consideration in blind via PCB manufacturing represents a critical design parameter. The aspect ratio, defined as the ratio of via depth to via diameter, directly influences the reliability of the plating process and the overall electrical performance of the finished product. Optimal aspect ratios for blind via PCB applications typically range from 1:1 to 10:1, depending on the specific technology and manufacturing capabilities employed.

Plating processes for blind via PCB require specialized techniques to ensure complete copper coverage within the confined geometry of the via structure. Electroplating parameters must be carefully optimized to achieve uniform copper distribution and adequate thickness throughout the via barrel. Advanced plating chemistry and current density control systems are essential for maintaining consistent quality across production volumes.

Design Considerations and Engineering Applications

The implementation of blind via PCB technology requires careful consideration of multiple design parameters that directly impact both manufacturing feasibility and end-product performance. Signal integrity considerations become particularly critical in high-frequency applications where blind vias must maintain controlled impedance characteristics while minimizing signal degradation.

Thermal management represents another crucial aspect of blind via PCB design. The reduced cross-sectional area of blind vias compared to traditional through-hole vias can impact thermal conductivity, requiring engineers to implement appropriate thermal design strategies. This consideration becomes especially important in power electronics applications where heat dissipation is a primary concern.

The mechanical reliability of blind via PCB structures depends heavily on the quality of the via formation and plating processes. Proper adhesion between copper plating and substrate materials is essential for withstanding thermal cycling and mechanical stress encountered during normal operation. Advanced surface preparation techniques and optimized plating parameters contribute significantly to achieving the required reliability standards.

Design for manufacturability considerations in blind via PCB development include via positioning, size optimization, and compatibility with standard PCB manufacturing processes. Engineers must balance the desire for maximum density with practical manufacturing constraints to achieve cost-effective production while maintaining quality standards.

Solving Real-World Challenges with Blind Via PCBs

Many customers approach us with concerns about laser-drilled blind vias—ranging from plating voids and registration issues to long lead times for complex stackups. At Highleap, we address these challenges through:

- Tight process control for copper-filled blind vias

- Fast-turn capabilities even for HDI stackups with 2+N+2 layers

- X-ray and AOI inspection for every blind via layer

- Dedicated DFM review and engineering support

Applications in Modern Electronics

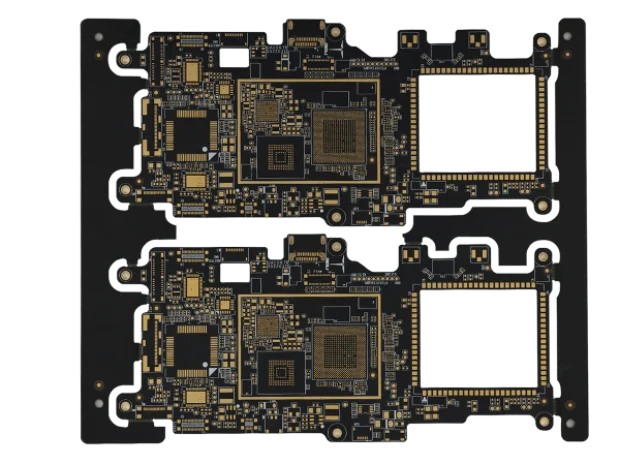

The versatility of blind via PCB technology has enabled its adoption across a wide range of electronic applications, from consumer electronics to aerospace systems. Mobile device manufacturers have particularly benefited from the space-saving advantages of blind via PCB designs, enabling the integration of complex functionality within increasingly compact form factors.

High-frequency communication systems represent another significant application area for blind via PCB technology. The ability to create short, controlled-impedance connections between layers makes blind vias ideal for minimizing signal propagation delays and reducing electromagnetic interference in radio frequency applications. This capability has proven essential in the development of advanced wireless communication systems and radar technologies.

Medical device applications have embraced blind via PCB technology for its ability to support miniaturized designs while maintaining the reliability required for life-critical applications. The precise dimensional control achievable with modern blind via PCB manufacturing processes enables the creation of highly reliable interconnections in implantable devices and diagnostic equipment.

Industrial automation systems benefit from blind via PCB technology through improved signal integrity and reduced electromagnetic interference. The selective layer connectivity provided by blind vias enables the creation of optimized ground planes and power distribution networks, contributing to overall system performance and reliability.

Quality Control and Testing Standards

The manufacturing of blind via PCB requires comprehensive quality control measures to ensure consistent performance across production volumes. X-ray inspection systems play a crucial role in verifying the integrity of blind via structures, enabling the detection of potential defects such as incomplete drilling, plating voids, or dimensional variations.

Electrical testing procedures for blind via PCB must address the unique characteristics of blind via structures. Continuity testing, resistance measurements, and high-voltage isolation testing are essential components of a comprehensive quality assurance program. Advanced testing equipment capable of accessing individual blind vias is necessary for thorough evaluation of manufacturing quality.

Cross-sectional analysis represents a critical quality control technique for blind via PCB manufacturing. Microscopic examination of prepared cross-sections enables the verification of via geometry, plating thickness, and interface quality. This destructive testing approach provides valuable feedback for process optimization and quality improvement initiatives.

Statistical process control implementation in blind via PCB manufacturing requires careful monitoring of key process parameters including drill depth accuracy, plating thickness uniformity, and dimensional stability. Real-time monitoring systems and automated data collection enable proactive quality management and rapid response to process variations.

Our Blind Via PCB Manufacturing Services

We support a wide range of HDI PCB designs featuring blind vias, offering:

| Capability | Specification |

|---|---|

| HDI Stackups | 1+N+1, 2+N+2, 3+N+3 |

| Via Types | Blind via, stacked blind via, via-in-pad |

| Via Diameter | 75 µm – 200 µm |

| Aspect Ratio | Up to 1:1 |

| Copper Fill | Supported (filled & capped) |

| Surface Finish | ENIG, Immersion Silver, OSP |

| Certification | IPC Class 2/3, ISO 9001, ISO 13485 |

| Volume | Prototype to mass production (100K+ pcs) |

Future Developments and Industry Trends

The continued evolution of blind via PCB technology is driven by the ongoing demand for increased functionality and miniaturization in electronic devices. Emerging applications in artificial intelligence, 5G communications, and Internet of Things devices are pushing the boundaries of what is achievable with current blind via PCB technology.

Advanced materials development is opening new possibilities for blind via PCB applications. Low-loss dielectric materials, high-thermal-conductivity substrates, and improved copper plating formulations are enabling the creation of blind via PCB designs with enhanced performance characteristics. These material advances support the development of next-generation electronic systems with improved efficiency and reliability.

Manufacturing process innovations continue to expand the capabilities of blind via PCB technology. Sequential lamination techniques, embedded component integration, and advanced surface finishing processes are enabling the creation of increasingly complex blind via PCB structures. These technological advances support the development of highly integrated electronic systems with reduced size and weight.

The integration of artificial intelligence and machine learning technologies into blind via PCB manufacturing processes promises to improve quality control, optimize process parameters, and reduce manufacturing costs. Predictive maintenance systems and automated defect detection capabilities will contribute to increased manufacturing efficiency and improved product quality.

📞 Have a question or need a blind via design reviewed?

Reach out to our technical team for expert guidance and cost-saving strategies.

Conclusion

Blind via PCB technology represents a fundamental advancement in printed circuit board manufacturing, enabling the creation of high-density interconnections essential for modern electronic devices. The successful implementation of blind via PCB designs requires careful attention to manufacturing processes, design optimization, and quality control measures.

At Highleap PCB, our advanced manufacturing capabilities and extensive experience in blind via PCB production enable us to deliver high-quality solutions for the most demanding applications. Our state-of-the-art equipment and skilled engineering team ensure that your blind via PCB projects meet the highest standards of quality and reliability.

The future of blind via PCB technology holds significant promise for continued innovation and expanded applications. As electronic devices become increasingly sophisticated and compact, the importance of advanced PCB technologies like blind vias will continue to grow, driving further developments in manufacturing processes and design methodologies.