The integration of Computer-Aided Manufacturing (CAM) engineering in printed circuit board (PCB) production is pivotal in translating intricate design concepts into tangible, high-performance products. CAM engineering serves as the critical interface between theoretical design and real-world manufacturing, facilitating the accurate execution of complex electrical designs while adhering to stringent quality standards. This comprehensive technical analysis delves into the nuances of CAM engineering, elucidating the advanced requirements, best practices, and quality control methodologies that form the bedrock of professional PCB manufacturing.

CAM Engineering Responsibilities and Advanced Technical Requirements

CAM engineers are entrusted with the fundamental task of validating PCB design files, ensuring they align with both the design specifications and the inherent limitations of the manufacturing processes. This validation requires a profound understanding of the underlying PCB fabrication methods, the properties of raw materials, and the operational constraints of manufacturing equipment. In particular, the CAM engineer must scrutinize the design for manufacturability, pinpointing potential issues that could compromise production efficiency, yield, or product reliability. Key areas of analysis include dimensional accuracy, material compatibility, and overall process feasibility.

A core function of CAM engineering is the Design Rule Checking (DRC) process, which rigorously verifies that the design adheres to the predefined manufacturing constraints, including minimum feature sizes, spacing specifications, and aspect ratio limits. The CAM engineer must be adept in interpreting these constraints, ensuring that the design meets both industry and customer-specific standards. For instance, conventional manufacturing processes generally require a minimum trace width of 0.1mm, while advanced technologies, such as fine-pitch processing, can accommodate trace widths as small as 0.05mm.

File integrity is another critical aspect of CAM engineering. Ensuring the Gerber RS-274X files are free from data corruption is essential to avoiding manufacturing discrepancies and costly delays. This involves validating aperture definitions, verifying coordinate precision, and ensuring accurate layer and drill hole specifications. Furthermore, CAM engineers must scrutinize drill files to ensure the correct assignment of tool paths, hole sizes, and precision in coordinate data. Any discrepancies must be promptly addressed before advancing to the production phase.

The layer stack-up verification process ensures that design specifications are fully compatible with manufacturing capabilities. CAM engineers must confirm that dielectric material thickness, copper weight, and impedance control parameters fall within the available material options. The verification of these parameters requires in-depth knowledge of material science and its impact on the electrical and mechanical properties of the final PCB.

Optimizing Manufacturing Data Processing and Enhancing Efficiency

Processing manufacturing data is a highly specialized and complex aspect of CAM engineering, demanding advanced technical skills and meticulous attention to detail. The objective is to streamline the data flow while maximizing production efficiency, all while maintaining product quality. CAM engineers employ intelligent drill program optimization to minimize drilling time without sacrificing hole quality or tool life. This requires sophisticated tool path planning and sequencing to ensure the most efficient use of drilling equipment, considering factors like material properties and tool wear.

In terms of panelization design, CAM engineers are tasked with ensuring that the design is optimized for manufacturing efficiency. The goal is to strike a balance between material usage, manufacturing constraints, and assembly requirements. The selected panel configuration must support automation systems, such as pick-and-place machines, while maintaining structural integrity throughout the manufacturing stages. Engineers must also consider standard panel dimensions and breakaway tab specifications to optimize material usage without compromising the manufacturability of the design.

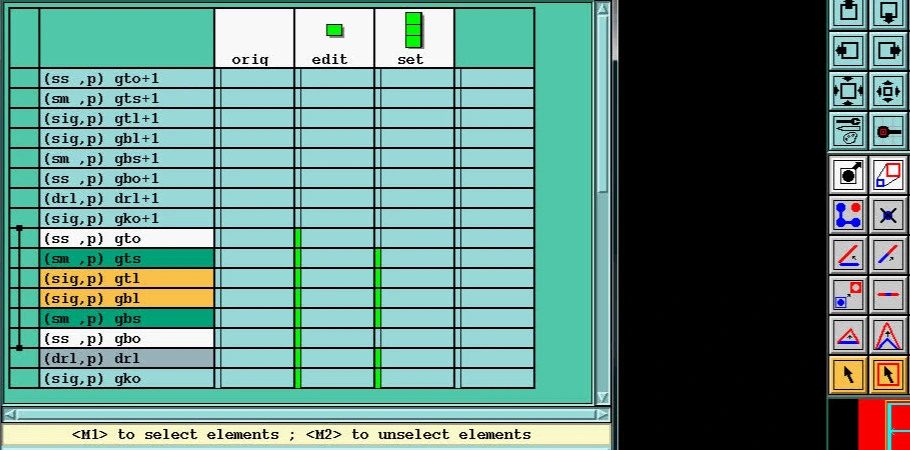

Gerber file processing involves utilizing advanced CAM software to convert design data into actionable manufacturing instructions. The CAM engineer must possess expertise in the nuances of each manufacturing step, including copper feature definition, solder mask specifications, and silk screen placement. Each step of the Gerber file processing chain must be meticulously calibrated to reflect the exact requirements of the production process.

Additionally, manufacturing documentation generation is critical in communicating design specifications to the production team. CAM engineers are responsible for producing comprehensive fabrication drawings, drill charts, and detailed manufacturing notes that communicate design intent with precision, thereby minimizing the risk of errors during production.

Rigorous Quality Control and Adherence to Manufacturing Standards

Quality control in CAM engineering is not merely a precautionary measure; it is an integral component of the entire manufacturing process. The goal is to ensure that all design files are meticulously reviewed for compliance with industry standards and manufacturing feasibility. By conducting thorough verification protocols, CAM engineers identify potential manufacturing challenges before they arise. This includes scrutinizing issues such as insufficient annular ring dimensions, minimum spacing violations, and concerns related to aspect ratios.

An essential aspect of CAM quality control is drill file optimization, which ensures that drilling parameters align with production capabilities. CAM engineers must select tools based on precise hole size requirements, surface finish specifications, and tool life considerations, ensuring consistency and efficiency throughout the manufacturing process. Industry-standard drill tolerances typically require a finished hole diameter precision of ±0.025mm, underscoring the importance of meticulous tool selection and program optimization.

The specification of manufacturing parameters further highlights the importance of technical expertise. CAM engineers must define appropriate etching, plating, and surface finishing processes based on both design requirements and material properties. These parameters must be clearly outlined in the manufacturing documentation to ensure accurate communication with production teams and prevent errors during the manufacturing phase.

To facilitate ongoing process improvement, CAM engineers rely on feedback systems to monitor production performance and identify potential areas for enhancement. By analyzing manufacturing defects, yield data, and customer feedback, engineers can refine the CAM processes, leading to improved efficiency, reduced waste, and better overall quality control.

Embracing Advanced Manufacturing Techniques and Cutting-Edge Technologies

As PCB designs evolve in complexity, CAM engineering must adapt to support new technologies and manufacturing techniques. High-Density Interconnect (HDI) boards, for example, present unique challenges that demand specialized knowledge in sequential lamination, microvia formation, and build-up layer processing. The need for precise registration control and sophisticated equipment for HDI manufacturing significantly influences CAM engineering processes.

In the realm of embedded component integration, CAM engineers are tasked with coordinating the placement of components, the creation of cavities, and the interconnection of components within the PCB structure. This integration requires close collaboration with design teams, component suppliers, and manufacturing staff to ensure that these advanced designs can be efficiently manufactured.

Flexible and rigid-flex PCBs represent another area requiring specialized CAM engineering expertise. These designs involve multi-substrate constructions and flexible materials, presenting challenges in material handling, adhesive system design, and assembly techniques. CAM engineers must have a thorough understanding of these materials and techniques to ensure that flexible and rigid-flex boards meet both design and manufacturing requirements.

Emerging surface finishing technologies, such as immersion gold and electroless nickel, necessitate advanced CAM engineering knowledge. Each of these finishes requires specific manufacturing parameters and quality control measures to ensure that they are applied correctly, providing the required electrical and mechanical properties.

The Role of Advanced CAM Tools and Software in Efficient Engineering

CAM engineering relies heavily on robust software systems to streamline operations and enhance precision. Advanced CAM software platforms provide a comprehensive suite of tools for automated design rule checking, panelization, and data processing. CAM engineers must be proficient in multiple software systems to accommodate diverse manufacturing requirements, ensuring that all aspects of the design are optimally processed for production.

Moreover, database management systems are essential for organizing and managing manufacturing data, ensuring version control, backup protocols, and system integrity. These systems must support collaborative workflows, enabling smooth coordination between various stakeholders while maintaining comprehensive audit trails for quality assurance.

Automated verification tools are increasingly utilized to reduce manual errors and increase the efficiency of the verification process. These tools enable CAM engineers to quickly identify discrepancies or issues that may arise during the manufacturing process, thus ensuring higher accuracy and consistency compared to traditional manual methods.

Conclusion: The Evolution and Future of CAM Engineering in PCB Manufacturing

As PCB designs become more intricate and manufacturing processes more demanding, the importance of professional CAM engineering is expected to grow. CAM engineers serve as the critical link between design and production, ensuring that complex designs are manufacturable while meeting the highest standards of quality and performance. Their expertise in data validation, optimization, and quality control ensures that every PCB meets the demanding requirements of modern electronic applications.

The ongoing development of CAM engineering techniques will play a pivotal role in the future of PCB manufacturing, particularly as new technologies, materials, and processes continue to emerge. At Highleap PCB, our CAM engineers are committed to delivering optimal manufacturing solutions by embracing cutting-edge technologies and continuously refining our processes to meet the ever-evolving needs of the electronics industry.

As the industry continues to push the boundaries of what is possible in PCB design and manufacturing, professional CAM engineering will remain at the heart of producing next-generation electronic products that meet the increasing demands of performance, reliability, and innovation.