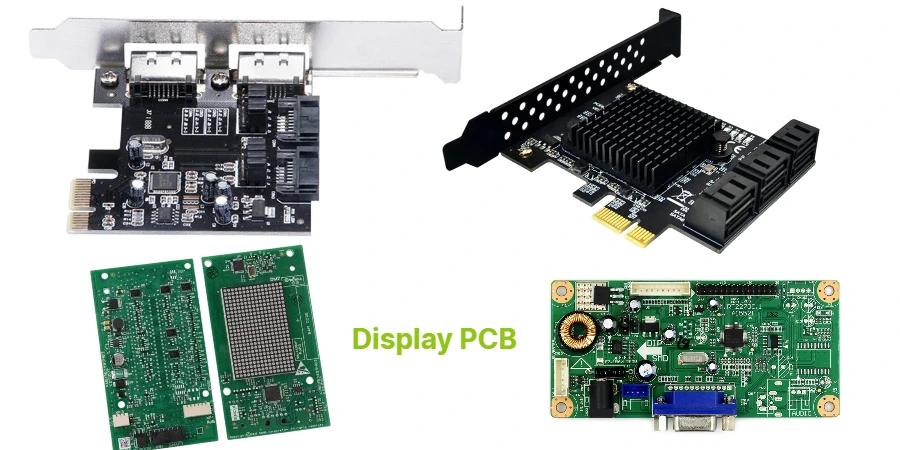

At Highleap PCB Factory, we've manufactured Display PCBs for global brands since 2008. From our ISO 9001 certified facility in Shenzhen, we deliver display controller boards, driver circuits, and complete display systems that power everything from smartphones to stadium displays.

Modern display technology demands sophisticated PCB designs integrating timing controllers, power management, signal processing, and interface circuits within increasingly compact form factors. Our expertise covers all display technologies including LCD controllers, OLED drivers, LED display modules, and emerging technologies like E-ink and microLED systems.

Display PCB Design Architecture and Signal Management

Display PCB design requires comprehensive understanding of video signal processing, power distribution, and electromagnetic compatibility. The fundamental challenge lies in managing high-speed digital signals while maintaining excellent visual performance and minimizing electromagnetic interference.

Core Display PCB Components:

• Timing Controllers (TCON): Precision circuits managing pixel refresh rates, synchronization signals, and video data flow with nanosecond timing accuracy for flicker-free display operation

• Power Management Systems: Multi-rail power supplies delivering various voltages from 1.2V logic to 15V gate drivers with exceptional regulation and low noise characteristics

• Interface Controllers: HDMI, DisplayPort, LVDS, and MIPI DSI interfaces supporting resolutions up to 8K with signal integrity optimization and EMI compliance

• Display Driver Integration: Sophisticated driver circuits for specific panel technologies including source drivers, gate drivers, and gamma correction circuits

Display PCBs must handle pixel clock frequencies exceeding 500 MHz while maintaining signal integrity across multiple layers. Our designs incorporate controlled impedance routing, differential pair matching, and advanced layer stack-ups optimized for high-frequency performance.

We also manufacture related display ecosystem products including OLED PCB assemblies for premium applications, LCD PCB controllers for cost-effective solutions, LED Display PCB modules for high-brightness outdoor use, touch screen integration boards, and specialized backlight control circuits.

Advanced Display PCB Manufacturing Processes

Professional Display PCB manufacturing employs specialized fabrication techniques optimized for high-speed digital signals and precise analog performance. Material selection and process control directly impact display quality, electromagnetic compliance, and long-term reliability.

High-Speed Signal Optimization:

High-frequency PCB substrates including Rogers and Isola materials provide excellent signal integrity for demanding display applications. These materials maintain stable electrical properties across temperature variations critical for automotive and industrial display systems.

For cost-sensitive consumer applications, premium FR4 PCB substrates with controlled dielectric properties support most display implementations while maintaining excellent price-performance ratios.

Precision Manufacturing Techniques:

• HDI Construction: HDI PCB technology enables ultra-compact display designs with via-in-pad structures supporting fine-pitch display controller ICs

• Thermal Management: Strategic copper pours, thermal vias, and aluminum-core substrates for high-power display applications requiring active heat dissipation

• EMI Mitigation: Comprehensive shielding strategies including ground planes, guard traces, and filtered power delivery to ensure EMC compliance

• Flexible Integration: Flex PCB solutions for curved displays, foldable devices, and space-constrained applications

Professional Display PCB Assembly and Testing

Display PCB assembly requires precision placement and soldering techniques for fine-pitch controller ICs, ensuring optimal electrical performance and long-term reliability. Component selection and assembly processes directly impact display quality and system performance.

Critical Assembly Considerations:

Display controller ICs utilize advanced packaging including fine-pitch BGA and QFN packages requiring specialized SMT assembly equipment. Placement accuracy within ±25 μm ensures reliable connections for high-speed digital interfaces while preventing thermal damage to sensitive components.

Display PCB Categories:

• Smartphone Display PCBs: Ultra-compact main boards supporting high refresh rates, touch integration, and power efficiency optimization

• Automotive Display Controllers: Ruggedized designs meeting AEC-Q100 standards with extended temperature operation and EMC compliance

• Industrial Display PCBs: Enhanced reliability designs for medical devices, factory automation, and outdoor installations with conformal coating options

• Large Format Display Systems: High-power controllers for digital signage, video walls, and stadium displays with advanced thermal management

Advanced Assembly Technologies:

Sequential lamination and blind via construction enable complex routing in minimal board thickness. Specialized reflow profiles protect sensitive display components while ensuring reliable solder joint formation across mixed component types.

Display PCB Applications and Market Solutions

HILPCB delivers Display PCB manufacturing solutions across consumer electronics, automotive systems, medical devices, and industrial applications, ensuring reliable visual performance and production scalability.

Consumer Electronics Applications: Display PCBs for smartphones, tablets, laptops, and gaming devices prioritize compact design, power efficiency, and high-resolution support. Recent projects include 120Hz display controllers and foldable display integration systems.

Automotive Display Systems: Dashboard instrument clusters, infotainment displays, and heads-up display controllers meeting automotive qualification standards. Enhanced EMC performance and temperature cycling validation for reliable vehicle operation.

Industrial and Medical Displays: Professional monitor controllers for medical imaging, industrial automation, and outdoor digital signage. Regulatory compliance including FDA and CE medical device standards with enhanced long-term reliability.

Emerging Display Technologies: Micro-LED display controllers, transparent display systems, and AR/VR display interfaces representing the next generation of visual technology applications.

Why Choose HILPCB for Display PCB Manufacturing

At HILPCB, we deliver comprehensive Display PCB manufacturing and assembly solutions, accelerating your product development from prototype through high-volume production. Our expertise in high-speed digital design, precision assembly, and display technology ensures reliable performance and faster time-to-market.

Manufacturing Excellence:

- Advanced Capabilities: 2-20 layer PCBs with HDI construction, controlled impedance, and specialized materials for demanding display applications

- Quality Standards: ISO 9001:2015 certified processes with IPC-A-600 compliance and comprehensive testing protocols

- Rapid Prototyping: 5-7 day prototype delivery with engineering support and design optimization services

- Global Compliance: RoHS and REACH certified with comprehensive material documentation and regulatory support

Technical Advantages: Our Shenzhen location provides direct access to major display panel manufacturers and component suppliers, enabling rapid technology adoption and cost optimization. Local supply chains reduce lead times while maintaining quality standards equivalent to global facilities.

Frequently Asked Questions About Display PCB Manufacturing

Q: How quickly can Chinese factories deliver Display PCB prototypes? A: Our standard lead time is 5-7 days for Display PCB prototypes with express 3-day service available. Production quantities typically require 15-20 days with comprehensive testing and quality validation.

Q: What quality standards ensure reliable Display PCB manufacturing? A: We maintain ISO 9001:2015 certification with IPC-A-600 compliance. Every Display PCB undergoes electrical testing, signal integrity verification, and functional validation with actual display panels.

Q: Can you handle both simple LCD controllers and complex OLED drivers? A: Yes, we manufacture the complete range from basic segment displays to advanced 8K display controllers. Our capabilities include HDI construction, flexible circuits, and specialized assembly for all display technologies.

Q: Do you provide turnkey assembly including component sourcing? A: Our turnkey service includes component procurement, PCB fabrication, SMT assembly, and testing. We maintain authorized distributor relationships and provide component obsolescence management.

Q: What support do you offer for Display PCB design optimization? A: Our engineering team provides comprehensive design review including signal integrity analysis, power optimization, thermal management, and EMC compliance guidance to ensure successful manufacturing and performance.