Electronic devices are essential to modern life, supporting countless applications across various industries. From everyday household appliances to sophisticated communication systems, electronic devices are integrated into nearly every aspect of our daily routines. These devices operate by controlling the flow of electrical charge through semiconductors, enabling signal processing, communication, and control.

This article provides a comprehensive understanding of electronic devices, covering their definitions, working principles, classifications, components, fabrication processes, evolution, and their societal impact.

What is an Electronic Device?

An electronic device is any equipment that utilizes controlled electric charge to perform a specific function. These devices rely on components such as semiconductors (e.g., transistors, diodes), passive components (e.g., resistors, capacitors), and active components (e.g., integrated circuits) to manipulate electrical signals. The key feature of electronic devices is their ability to use electricity, primarily through semiconductor materials, to process information or execute tasks.

Key Features of Electronic Devices

- Electricity Control: Unlike mechanical or optical devices, electronic devices manipulate electrical energy to control current flow and process signals.

- Semiconductor Materials: Materials like silicon, germanium, and gallium arsenide enable controlled electrical conductivity, which is crucial for creating components like transistors.

- Discrete Components: Electronic devices often use individual components such as diodes, transistors, capacitors, and resistors to handle electrical signals.

- Integrated Circuits (ICs): ICs are microchips that integrate multiple components on a single semiconductor substrate, allowing for compact, efficient designs.

- Digital Logic: Many electronic devices rely on binary logic (0s and 1s) processed by ICs to manipulate data and make decisions.

- Analog Signal Processing: Some electronic devices handle continuous, analog signals such as sound, temperature, or light.

- Electron Flow Control: The operation of most electronic devices centers around the controlled flow of electrons in semiconductor materials.

Classification of Electronic Devices

Electronic devices can be classified based on their application, functionality, and complexity. The major categories include:

1. Consumer Electronics

These devices are commonly found in homes and personal settings:

- Smartphones

- Laptops and Tablets

- Televisions

- Smartwatches and Wearables

- Headphones and Earbuds

- Home Appliances (e.g., refrigerators, washing machines, microwaves, vacuum cleaners)

2. Industrial Electronics

Devices used in manufacturing, production, and industrial control systems:

- Programmable Logic Controllers (PLCs)

- Automation Systems

- Robotics

- Motor Drives

- Industrial Sensors and Actuators

3. Automotive Electronics

Electronics that enhance safety, comfort, and performance in modern vehicles:

- Engine Control Units (ECUs)

- Infotainment Systems

- Autonomous Driving Systems

- Sensors and Cameras for Advanced Driver Assistance Systems (ADAS)

- Electric Vehicle (EV) Battery Management Systems

4. Medical Electronics

Devices that aid in diagnostics, treatment, and patient monitoring:

- Electrocardiogram (ECG) Machines

- Ultrasound Scanners

- Pacemakers

- Blood Pressure Monitors

- Imaging Systems (MRI, CT Scanners)

5. Test and Measurement Instruments

Instruments used to test, analyze, and measure electrical signals and systems:

- Oscilloscopes

- Multimeters

- Signal Analyzers

- Power Meters

6. IoT Devices

Internet of Things (IoT) devices that communicate data with other systems or devices:

- Smart Thermostats

- Security Cameras

- Smart Lighting and Home Automation

- Wearable Health Monitors

- Smart Sensors

Key Components of Electronic Devices

Every electronic device, from consumer gadgets to industrial control systems, is built upon a set of core components that enable the control, conversion, and manipulation of electrical energy. These elements work together to deliver functionality, performance, and reliability across various applications.

Core Electronic Components and Materials

- Semiconductor Materials: The foundation of modern electronics. Silicon remains the most widely used due to its stable electrical properties, while germanium and gallium arsenide support high-speed and high-frequency performance in specialized applications.

- Discrete Semiconductor Devices: Include transistors, diodes, and thyristors that perform key operations such as switching, rectification, amplification, and power control in both analog and digital circuits.

- Integrated Circuits (ICs): Microchips that integrate thousands or millions of transistors, resistors, and capacitors into a compact silicon die, enabling complex processing, computation, and control within minimal space.

- Passive Components: Resistors, capacitors, and inductors maintain circuit stability, filter signals, divide voltages, and manage energy storage - ensuring smooth operation and noise suppression.

- Piezoelectric Materials: Crystals that generate electric charge under mechanical stress, widely used in sensors, actuators, and timing devices to convert between electrical and mechanical energy.

- Display Technologies: Modern visual interfaces including LCD, LED, and OLED panels that translate electrical signals into readable images or graphical data for user interaction.

- Sensors and Actuators: Detect physical changes such as temperature, pressure, or motion and convert them into electrical signals, enabling real-time monitoring and automated system control.

- Power Supply Systems: AC-DC and DC-DC converters regulate and distribute electrical energy to ensure consistent voltage and current for all device components, safeguarding stability and performance.

Fabrication of Electronic Devices

The fabrication of electronic devices involves a highly structured yet interconnected series of steps that transform raw semiconductor materials into functional end products. From wafer processing to assembly and testing, each stage requires precision, process control, and advanced engineering to ensure quality and reliability.

1. Semiconductor Fabrication

The process begins with semiconductor wafer preparation. Silicon wafers are oxidized to form dielectric layers, followed by photolithography, where UV light transfers intricate circuit patterns onto a photoresist layer. Doping introduces impurities to create n-type and p-type regions, while etching removes unwanted material to define circuit features. Thin films are deposited through chemical vapor deposition (CVD), physical vapor deposition (PVD), or atomic layer deposition (ALD). Metallization forms the interconnect layers that link transistors and other elements. After passivation and planarization, wafers undergo electrical testing and defect inspection before being diced into individual dies. Each die is then packaged through wire bonding or flip-chip methods, encapsulated, and subjected to final electrical testing and burn-in to ensure performance stability.

2. PCB Fabrication

PCB fabrication transforms design data into the physical foundation that interconnects electronic components. The process starts with CAD design and Gerber file generation, followed by selection of materials such as copper foil, fiberglass laminates, and prepreg. Inner layers are imaged and etched to form the circuit pattern, then inspected using Automated Optical Inspection (AOI). Layers are laminated under heat and pressure, forming a solid multilayer structure. Holes are drilled mechanically or with lasers, cleaned, and plated with copper to create vias. Outer layers are then imaged, plated, and etched. A solder mask is applied and cured to protect copper surfaces, followed by silkscreen printing of component markings. Surface finishes such as ENIG, HASL, or OSP are added to prevent oxidation and ensure solderability. Finally, boards are routed or V-scored, electrically tested for continuity and isolation, inspected optically and via X-ray (especially for HDI boards), then cleaned, dried, and packaged in anti-static materials for delivery.

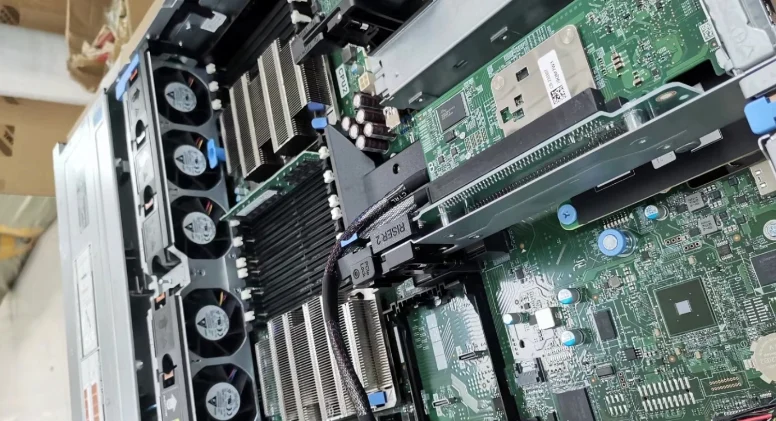

3. Component Assembly (PCBA)

PCB assembly (PCBA) mounts and connects all electronic components to the fabricated board. Solder paste is printed onto pads using a stencil printer, followed by automated pick-and-place machines that position components accurately. Reflow soldering melts the solder paste to form permanent electrical connections. Through-hole components are inserted and soldered by wave soldering, selective soldering, or manually for specialized parts.

Post-soldering inspections include AOI and X-ray checks to verify solder quality, particularly for BGAs and fine-pitch ICs. In-circuit testing (ICT) ensures electrical functionality, while functional tests simulate actual device operation. Some boards may receive conformal coating or potting for environmental protection before final cleaning and drying.

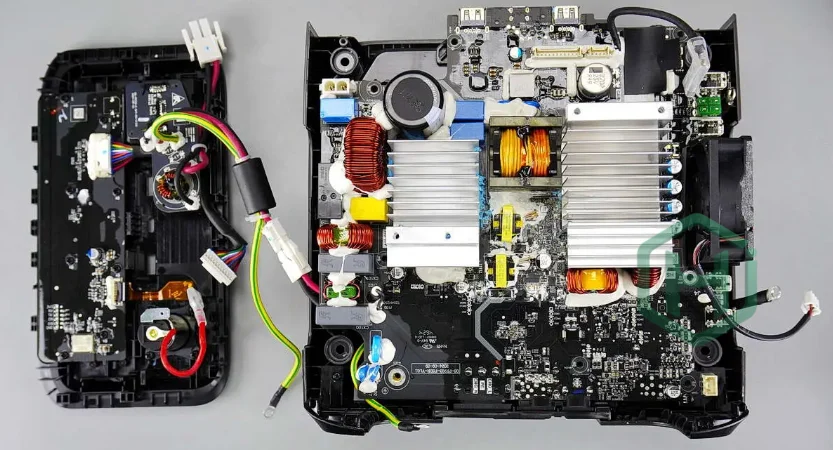

4. System Integration and Enclosure Assembly

Once PCBAs are completed, they are integrated into the final product enclosure. This stage includes molding or machining plastic or metal housings, installing displays, connectors, keypads, and sensors, and performing wire harnessing.

Thermal management components such as heat sinks, thermal pads, and fans are mounted to maintain temperature stability. The boards are fastened and aligned within the chassis, firmware is uploaded, and initial power-on testing is performed. EMI and EMC shielding materials are installed to ensure compliance with safety and electromagnetic standards.

5. Testing and Quality Control

Every electronic device undergoes extensive testing to verify performance, durability, and compliance. Functional testing ensures that circuits operate as intended. Reliability tests, including thermal cycling, humidity exposure, and vibration, simulate long-term usage. Signal integrity and impedance are validated for high-speed circuits, while EMC/EMI testing ensures regulatory compliance. Final inspections confirm mechanical accuracy, cleanliness, and labeling consistency before release.

6. Final Processing and Packaging

After all testing and verification, the finished products are cleaned, labeled, and serialized for traceability. Depending on the application, conformal coating or encapsulation may be applied to protect against moisture and dust. Each device is packaged in anti-static or vacuum-sealed bags with protective cushioning, along with full documentation, quality certificates, and production records. Final quality assurance approval is completed before shipment to customers or integration partners.

The complete process-from semiconductor wafer fabrication through PCB manufacturing, assembly, integration, and testing-forms the backbone of modern electronics production. Each stage must adhere to precise standards to ensure that every device meets electrical, thermal, and mechanical requirements. The result is a highly reliable, high-performance product ready for industrial, consumer, or specialized applications.

Evolution of Electronic Devices

The development of electronic devices has progressed significantly over the years, with key milestones marking each advancement:

- Vacuum Tubes (Early 1900s): Used for amplification and signal processing.

- Transistors (1947): Replaced vacuum tubes, enabling smaller, more reliable components.

- Integrated Circuits (1958): Allowed multiple components to be combined into a single chip, paving the way for miniaturization.

- Microprocessors (1971): Triggered the rise of personal computers.

- Personal Computers (1975): Early PCs like the Altair 8800 marked the beginning of the personal computing era.

- Mobile Phones (1973): The Motorola DynaTAC marked the birth of mobile communication.

- Smartphones (2007): The launch of the iPhone revolutionized both communication and computing.

- Internet of Things (IoT) (2009): Enabled everyday objects to connect and communicate via the internet.

The Societal Impact of Electronic Devices

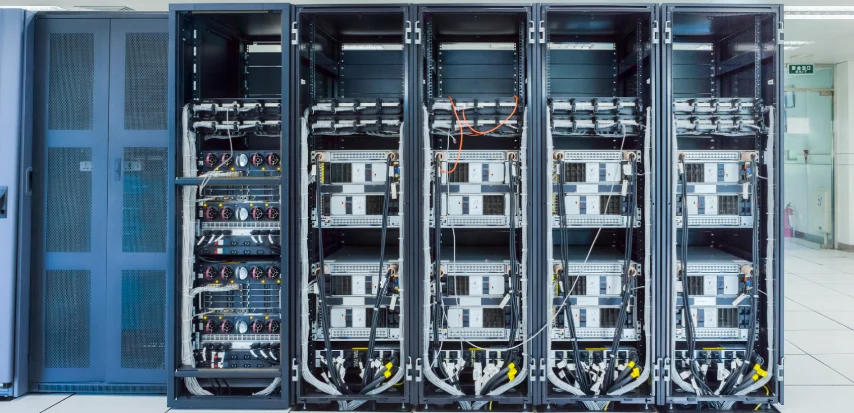

Electronic devices have had a profound impact on society, revolutionizing numerous sectors and improving everyday life. These devices have dramatically transformed computing and information technology, driving a digital revolution. With increased computing power, personal computers, smartphones, and cloud computing have changed how people work, socialize, and access information. Additionally, mobile phones, social media, and the internet have redefined communication, making real-time global connectivity possible. Electronic devices have also facilitated automation in industries, offices, and homes, improving efficiency and reducing the need for manual intervention.

In healthcare, medical electronics have enhanced diagnostics, treatment, and patient monitoring, leading to better outcomes. The entertainment and media sectors have been reshaped by devices like televisions, gaming consoles, and streaming services, altering how entertainment is consumed worldwide. On the environmental front, devices such as smart thermostats and energy-efficient appliances help reduce energy consumption, while environmental sensors contribute to sustainability efforts. Finally, electronic devices play a vital role in defense and space exploration, providing tools for satellite communication, advanced weaponry, and space technology.

Conclusion

Electronic devices are central to modern technological advancements. They range from basic household items to sophisticated systems enabling global communication, automation, and innovation. As technology continues to evolve, the development of more powerful, efficient, and interconnected devices promises to further enhance the way we live and work, driving further societal transformation in the years ahead.