Understanding Electronic Manufacturing Services (EMS)

In today’s fast-paced electronics industry, EMS play a pivotal role in bridging the gap between product design and large-scale production. As devices become smaller, smarter, and more complex, EMS companies provide the technical foundation that enables innovation, consistency, and efficiency across global supply chains.

From PCB assembly to system integration and final testing, EMS partners are vital for transforming electronic concepts into reliable, market-ready products. They support industries as diverse as consumer electronics, medical technology, automotive systems, and aerospace-each requiring precision manufacturing and stringent quality control.

What Is EMS Manufacturing?

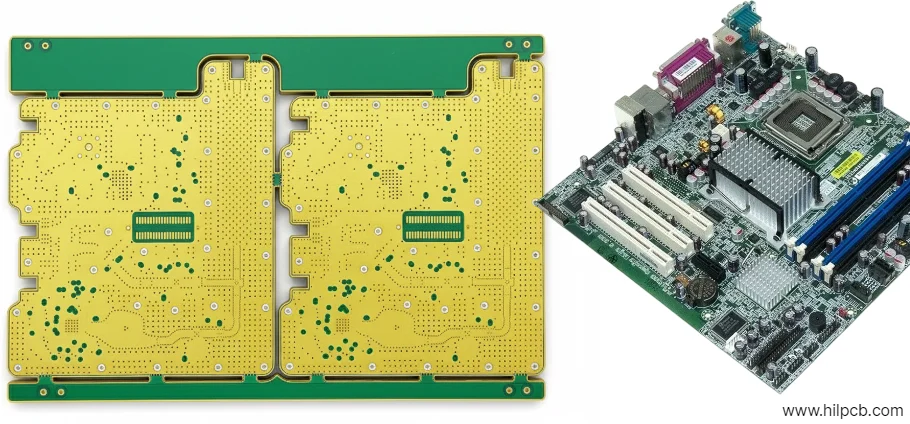

EMS manufacturing encompasses the full lifecycle of electronic product realization-from circuit design and prototyping to mass production and post-manufacturing services. It combines advanced manufacturing processes, automated assembly technologies, and engineering expertise to ensure consistent performance across all stages of production.

Typical EMS capabilities include:

- PCB Design and Layout Optimization: Translating schematics into manufacturable layouts with controlled impedance, thermal balance, and EMI management.

- Prototyping and Validation: Building and testing early-stage prototypes to verify electrical performance and manufacturability.

- Surface Mount and Through-Hole Assembly: High-speed SMT lines and precision THT assembly for complex multilayer boards.

- Component Sourcing and Supply Chain Management: Strategic procurement, inventory control, and vendor coordination to ensure on-time delivery.

- Testing and Quality Assurance: Functional testing, burn-in, ICT, and reliability validation before shipment.

- System Integration and Box Build: Assembling complete products, including mechanical, electrical, and software integration.

- After-Market Support: Repair, rework, and lifecycle management services for end products.

These services ensure that Original Equipment Manufacturers (OEMs) can focus on design and innovation while entrusting manufacturing precision and logistics to experienced partners.

Key Factors When Selecting an EMS Partner

Choosing the right EMS company is critical to ensuring product quality, reliability, and long-term collaboration. A few essential criteria include:

- Industry Experience and Technical Expertise:

Look for companies with extensive experience, proven project histories, and multidisciplinary teams familiar with your product type. - Certifications and Compliance:

ISO 9001, ISO 13485 (medical), IATF 16949 (automotive), and IPC-A-610 certifications indicate robust quality systems and regulatory compliance. - Manufacturing Capacity and Scalability:

The ability to manage both low-volume prototypes and high-volume production efficiently, without compromising quality or lead time. - Comprehensive Testing Capability:

In-house electrical, mechanical, and environmental testing ensures every product meets functional and reliability standards before shipment. - Transparent Communication and Project Management:

Clear communication channels, real-time reporting, and responsive customer support maintain trust and efficiency across development cycles. - Flexible Product Introduction Processes:

Advanced EMS providers follow structured NPI (New Product Introduction) workflows, including design review, pilot runs, validation testing, and mass production readiness.

Leading EMS Companies Worldwide

The global Electronic Manufacturing Services (EMS) industry is a vital pillar of the modern electronics supply chain. It encompasses a wide range of manufacturers specializing in printed circuit board assembly, system integration, and full product lifecycle management. These companies differ in scale, specialization, and regional strength, but all share a commitment to precision manufacturing, automation, and reliability.

Below is an overview of some of the most influential EMS companies shaping the global electronics landscape today.

1. Foxconn (Hon Hai Precision Industry, Taiwan)

Foxconn is the world’s largest EMS provider, well known for assembling products for major technology brands such as Apple, Dell, and Sony. With hundreds of thousands of employees and massive manufacturing facilities in China, India, Vietnam, and Mexico, Foxconn dominates high-volume consumer electronics manufacturing.

Beyond assembly, Foxconn invests heavily in smart manufacturing, robotics, and semiconductor packaging. Its services extend across consumer devices, automotive electronics, networking equipment, and medical instrumentation.

2. Flex Ltd. (Singapore)

Flex operates more than 100 facilities in over 30 countries, making it one of the most geographically diversified EMS providers. It supports a broad spectrum of industries-automotive, healthcare, communications, and industrial electronics.

Flex is known for its “Sketch-to-Scale” strategy, integrating design, prototyping, manufacturing, and logistics within a unified platform. The company emphasizes sustainability, digital supply chain integration, and additive manufacturing.

3. Jabil Inc. (United States)

Headquartered in Florida, Jabil offers engineering, supply chain, and manufacturing services for companies ranging from startups to global corporations. With operations in over 25 countries, Jabil’s strength lies in automation, industrial design, and precision manufacturing.

Its key business areas include healthcare, mobility, industrial automation, clean energy, and consumer electronics.

4. Wistron Corporation (Taiwan)

Originally part of Acer Inc., Wistron has evolved into one of the leading EMS and Original Design Manufacturers (ODMs). Its main focus areas are information and communication technology (ICT), cloud computing infrastructure, and consumer electronics.

Wistron operates production facilities in Asia, Mexico, and Europe and continues to invest in green manufacturing and circular processes.

5. Pegatron Corporation (Taiwan)

Pegatron is a global EMS provider known for partnerships with companies such as Apple, ASUS, and Microsoft. It specializes in designing and assembling computing, communication, and consumer electronics products.

In addition to manufacturing, Pegatron focuses on R&D, material innovation, and after-market support.

6. BYD Electronics (China)

A subsidiary of BYD Group, BYD Electronics offers diversified EMS and ODM solutions for smartphones, automotive electronics, and new energy systems. Its expertise extends to battery systems, IoT devices, and 5G communication modules.

7. Universal Scientific Industrial (USI, China)

USI is a prominent EMS and SiP (System-in-Package) specialist serving the automotive, industrial, and medical sectors. It provides miniaturized design, advanced packaging, and embedded system integration services.

8. Sanmina Corporation (United States)

Based in California, Sanmina is recognized for high-reliability manufacturing in sectors that demand stringent quality standards-such as aerospace, defense, medical, and communications.

Sanmina provides full design-to-distribution services, including prototyping, PCB fabrication, system assembly, and logistics management.

9. Plexus Corp. (United States)

Plexus, headquartered in Wisconsin, provides design, engineering, and manufacturing services for complex electronic products. It partners with OEMs in healthcare, industrial automation, and security systems, emphasizing close collaboration and lean production.

10. Celestica Inc. (Canada)

Celestica operates globally with facilities in Asia, Europe, and North America. It offers end-to-end product lifecycle solutions including design, supply chain optimization, manufacturing, and after-market services.

Its expertise spans aerospace, defense, renewable energy, and communications infrastructure.

11. Benchmark Electronics (United States)

Benchmark, headquartered in Arizona, specializes in complex engineering and integrated manufacturing for customers in aerospace, medical, and industrial automation sectors.

It provides RF, high-speed design, and precision production technologies that ensure product reliability.

12. Kinpo Electronics (Taiwan)

Part of the New Kinpo Group, Kinpo Electronics focuses on consumer and smart electronics, including IoT devices, power systems, and home appliances.

The company continues to advance digital manufacturing capabilities through AI and robotics.

13. Venture Corporation (Singapore)

Venture is one of Southeast Asia’s largest technology groups, offering integrated EMS, ODM, and product design services. It operates across life sciences, networking, industrial automation, and consumer electronics.

The company emphasizes innovation-driven partnerships, ISO-certified systems, and sustainable practices.

14. First Solar (United States)

Unlike traditional EMS firms, First Solar stands out as a solar technology manufacturer specializing in photovoltaic (PV) module production.

Its vertically integrated facilities handle every stage-from semiconductor film deposition to module assembly-ensuring environmental sustainability and efficiency.

15. Shenzhen Kaifa Technology (China)

Kaifa Technology is a major Chinese EMS provider recognized for turnkey manufacturing services, including PCB design, prototyping, component sourcing, and full-scale assembly.

Its strengths lie in storage systems, metering, and medical devices.

16. Ryder Industries (China)

Ryder Industries delivers end-to-end EMS solutions for consumer electronics, healthcare, and industrial products. Based in Shenzhen, it provides firmware development, software programming, and full hardware prototyping.

17. Fuji Electric (Japan)

Fuji Electric combines EMS expertise with power electronics, energy solutions, and retail systems. Its products include inverters, turbines, and power modules used in industrial automation and renewable energy systems.

18. Infineon Technologies (Germany)

Infineon is primarily a semiconductor manufacturer but acts as a key EMS partner for automotive, industrial, and security electronics.

It develops power semiconductors, sensors, and microcontrollers that serve as core components in smart systems.

19. Keysight Technologies (United States)

Keysight specializes in electronic test and measurement equipment, supporting EMS operations with modular instruments, wireless testing platforms, and embedded software.

Its solutions ensure precision and compliance throughout the design and production stages.

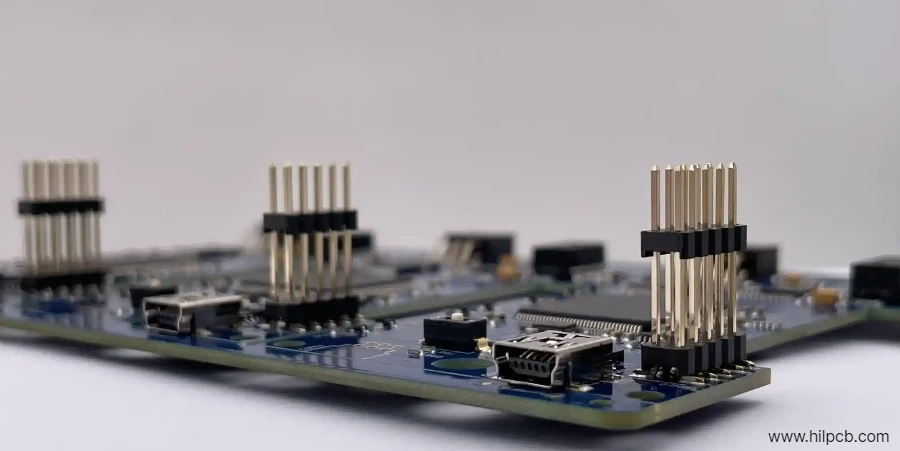

20. HILPCB Factory (China)

HILPCB Factory is a professional PCB manufacturing and assembly provider offering one-stop EMS support for global clients.

Its core services include multilayer PCB fabrication, high-frequency board production, prototype assembly, and turnkey EMS solutions.

HILPCB integrates engineering expertise with automated SMT lines and strict quality control systems to ensure precision and reliability across applications.

Advantages and Challenges of EMS Collaboration

Partnering with an EMS provider offers numerous advantages, though it also presents challenges that must be managed carefully.

Advantages:

- Access to specialized expertise and technology

- Reduced operational costs and time-to-market

- Improved scalability and resource efficiency

- Enhanced product quality and traceability

- Streamlined supply chain management

Challenges:

- Partial loss of direct process control

- Risk of intellectual property exposure

- Dependence on third-party timelines and priorities

- Potential communication barriers across regions

Strong partnerships are built on transparency, aligned goals, and continuous quality improvement to mitigate these challenges effectively.

The Future of EMS Manufacturing

The EMS landscape is rapidly evolving with advances in automation, digital twins, and smart manufacturing. The integration of AI-driven analytics, robotics, and Industry 4.0 connectivity is redefining how electronics are designed, produced, and delivered.

Future EMS firms will not only manufacture products-they will co-create technology ecosystems that merge design, data, and digital intelligence. As sustainability becomes a central focus, eco-friendly materials, recyclable designs, and energy-efficient processes will further shape the next generation of electronic manufacturing.

Conclusion

Electronic Manufacturing Services (EMS) form the backbone of today’s electronics industry. By combining precision engineering, global logistics, and deep technical expertise, EMS providers enable innovation at every stage-from concept to consumer.

Selecting the right EMS partner is about more than outsourcing; it’s about building a long-term collaboration that drives quality, flexibility, and market success in an increasingly complex world of connected electronics.