LCD technology powers 80% of the world's displays, from smartphones to 85-inch TVs. While newer technologies capture attention, LCD remains the reliable workhorse driving everything from medical monitors to automotive dashboards, and success depends on well-engineered LCD PCBs.

HILPCB has manufactured LCD PCBs since 2005, delivering reliable solutions for consumer electronics, automotive systems, industrial equipment, and medical devices. Our boards power millions of devices worldwide, from cost-effective consumer products to precision medical imaging systems.

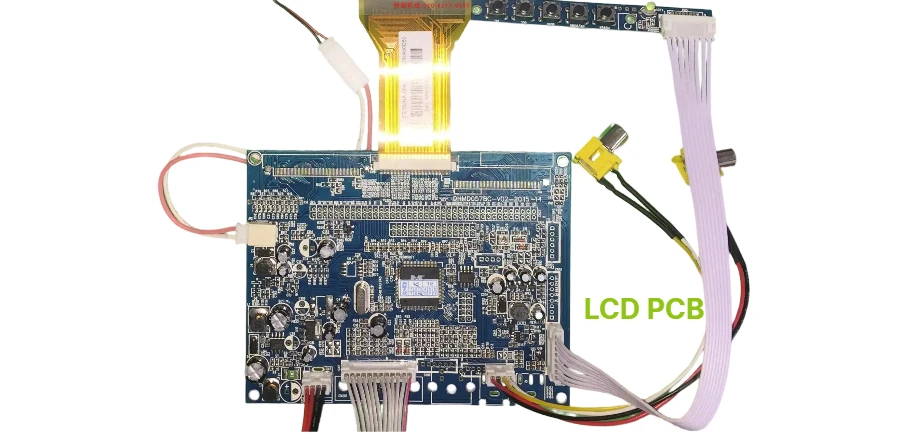

LCD PCB design encompasses timing controllers, backlight management, power distribution, and interface circuits supporting resolutions from basic segment displays to 8K video systems. Our expertise covers all LCD technologies including TN, IPS, VA panels, and specialized applications like transflective displays for outdoor use.

LCD PCB Design Fundamentals and Power Management

LCD PCB design requires comprehensive understanding of liquid crystal technology, backlight systems, and power efficiency optimization. The fundamental challenge lies in managing multiple voltage rails, precise timing signals, and backlight control while maintaining excellent signal integrity and cost effectiveness.

Core LCD PCB Components:

• Timing Controllers (TCON): Precision circuits managing pixel refresh, synchronization signals, and video processing with microsecond timing accuracy for stable image quality

• Backlight Control Systems: LED driver circuits with current regulation, dimming control, and thermal protection enabling uniform brightness and extended operational life

• Multi-Voltage Power Systems: Regulated power supplies delivering logic voltages (3.3V, 5V), analog supplies (12V), and gate driver voltages with excellent load regulation

• Interface Management: LVDS, MIPI DSI, eDP, and legacy parallel interfaces supporting various input sources with signal conditioning and ESD protection

LCD displays require precise voltage sequencing during power-up and power-down cycles to prevent panel damage and ensure reliable operation. Our LCD PCB designs implement comprehensive power management with proper sequencing control and fault protection mechanisms.

We manufacture complete LCD display systems including LCD display controller boards, LCD backlight driver PCBs, LCD timing controller circuits, touch screen integration boards, LCD power management modules, and industrial LCD interface adapters for specialized applications.

Proven LCD PCB Manufacturing Processes

Professional LCD PCB manufacturing employs established fabrication techniques optimized for cost-effectiveness, reliability, and high-volume production. Material selection and process control ensure consistent electrical performance while maintaining competitive pricing for mass market applications.

Optimized Material Selection:

Standard FR4 PCB substrates provide excellent electrical properties and cost-effectiveness for most LCD controller applications. High-quality materials from Shengyi and Kingboard ensure consistent dielectric properties and reliable long-term performance.

For demanding applications, high-Tg materials support extended temperature operation required for automotive and industrial LCD systems operating from -40°C to +125°C with enhanced thermal stability.

Efficient Manufacturing Techniques:

• Standard Layer Construction: 4-8 layer designs optimized for LCD controller requirements with controlled impedance and proper power distribution

• Cost-Effective Assembly: Automated SMT processes supporting both fine-pitch components and through-hole devices commonly used in LCD applications

• Thermal Management: Strategic copper pours and thermal vias for backlight driver heat dissipation with aluminum-core options for high-power applications

• Volume Optimization: Manufacturing processes scaled for high-volume production with consistent quality and competitive pricing

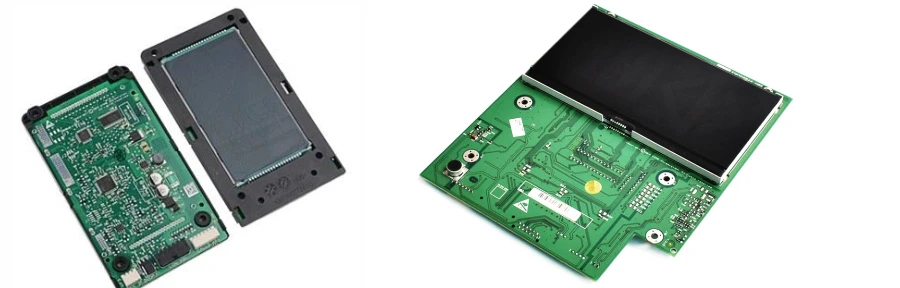

Comprehensive LCD PCB Assembly and Testing

LCD PCB assembly combines precision SMT techniques with reliable through-hole assembly for connectors and high-power components. Our assembly processes ensure optimal electrical performance while maintaining cost-effectiveness for volume production applications.

Proven Assembly Processes:

LCD controller ICs typically use mainstream packaging including QFP, TQFP, and standard BGA packages requiring reliable SMT assembly with proven processes. Component placement accuracy and reflow profiles optimized for mixed component types ensure reliable solder joint formation.

LCD PCB Application Categories:

• Consumer LCD PCBs: TV main boards, monitor controllers, and mobile device displays optimized for cost-effectiveness and reliable performance

• Automotive LCD Systems: Dashboard clusters, infotainment displays, and rear-seat entertainment meeting automotive qualification standards and EMC requirements

• Industrial LCD Controllers: HMI displays, factory automation interfaces, and outdoor displays with enhanced reliability and environmental protection

• Medical LCD PCBs: Diagnostic imaging displays, patient monitoring systems, and surgical displays meeting medical device regulations and safety standards

Reliable Testing Protocols:

Comprehensive electrical testing including in-circuit testing (ICT), functional verification with actual LCD panels, and burn-in testing for critical applications. Environmental testing for automotive and industrial applications ensures reliable operation across specified temperature ranges.

LCD PCB Applications and Market Solutions

HILPCB delivers LCD PCB manufacturing solutions across diverse industries, providing reliable performance and cost-effective production scaling from prototype development through high-volume manufacturing for global markets.

Consumer Electronics Applications: LCD PCBs for televisions, computer monitors, tablets, and gaming displays prioritizing cost optimization while maintaining reliable performance. Recent projects include 4K TV controllers and energy-efficient monitor systems with advanced power management.

Automotive LCD Integration: Instrument cluster displays, navigation systems, and passenger entertainment meeting automotive environmental standards. Enhanced EMC compliance and temperature qualification for reliable vehicle integration across global markets.

Industrial and Medical Systems: Factory automation displays, medical imaging monitors, and outdoor digital signage systems requiring enhanced reliability and regulatory compliance. Specialized designs for harsh industrial environments with conformal coating and extended temperature operation.

Specialized LCD Applications: Avionics displays, marine navigation systems, and military applications requiring enhanced reliability and specialized certifications. Custom solutions for unique requirements including high-altitude operation and radiation hardening.

Cost-Effective LCD PCB Manufacturing Services

At HILPCB, we deliver comprehensive LCD PCB manufacturing and assembly solutions, providing reliable performance and competitive pricing from prototype through high-volume production. Our expertise in conventional design techniques and volume optimization ensures cost-effective solutions without compromising quality.

Manufacturing Efficiency:

- Proven Processes: Standard layer constructions, established assembly techniques, and volume-optimized manufacturing for competitive pricing

- Quality Assurance: ISO 9001:2015 certified with IPC-A-600 compliance and comprehensive testing protocols ensuring reliable performance

- Flexible Volumes: Efficient handling from prototype quantities through millions of units with optimized pricing for each production phase

- Global Compliance: RoHS and REACH certified with automotive and medical certifications available for specialized applications

Market Advantages: Our position in Shenzhen provides access to comprehensive PCB supply chains including specialized LCD controller components, advanced materials, and testing equipment suppliers, enabling cost optimization and rapid scaling while maintaining international quality standards.

Frequently Asked Questions About LCD PCB Manufacturing

Q: Why choose Chinese manufacturers for LCD PCB production? A: China has a mature electronics manufacturing ecosystem with comprehensive PCB supply chains and component availability. Chinese manufacturers offer 40-60% cost savings while maintaining international quality standards and faster delivery through local component sourcing and established manufacturing processes.

Q: How do you ensure consistent quality for high-volume LCD PCB orders? A: We maintain automated production lines with statistical process control and comprehensive testing at each stage. Our quality system includes incoming inspection, in-process monitoring, and final testing with documented traceability.

Q: What's the typical lead time for LCD PCB manufacturing? A: Standard prototypes are delivered within 7-10 days with production quantities requiring 15-20 days. We maintain inventory of common LCD components to reduce lead times and offer expedited services for urgent projects.

Q: Can you handle both simple character displays and complex video controllers? A: Yes, we manufacture the complete range from basic segment displays to advanced 8K video controllers. Our capabilities include both through-hole and SMT assembly with flexible volume handling.

Q: Do you provide design optimization services for LCD PCBs? A: Our engineering team provides comprehensive design review including power optimization, signal integrity analysis, and cost reduction guidance. We identify potential issues before manufacturing and suggest improvements for performance and manufacturability.