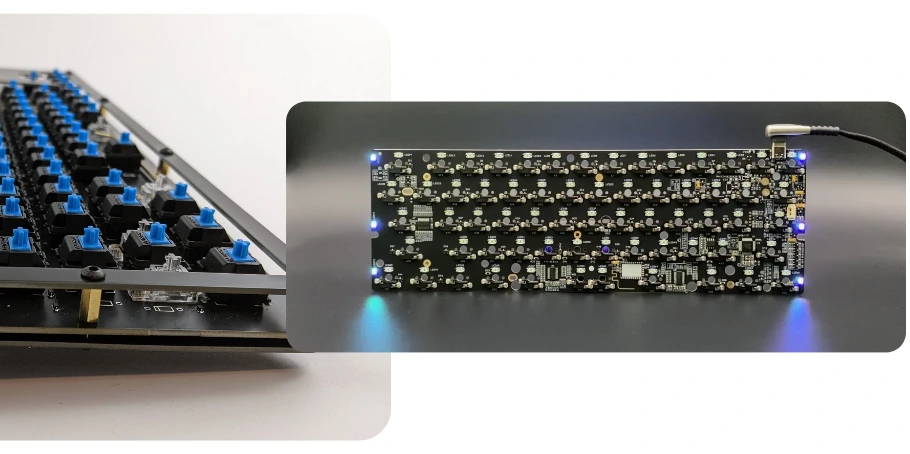

At HILPCB, we approach every PCB assembly project with the same standard of precision — whether it’s a high-frequency communication board, a complex HDI design, or a mechanical keyboard PCB Assembly for consumer peripherals. What sets us apart is not just our ability to manufacture PCBs, but to deliver end-to-end assembly services that transform bare boards into finished, market-ready products.

For mechanical keyboards, that means more than soldering switches and placing components. It requires understanding layout ergonomics, ensuring long-term durability, integrating RGB lighting or wireless modules, and maintaining flawless quality across every unit. From enthusiast-level custom builds to large-scale OEM production, our assembly lines combine automation with skilled craftsmanship to meet the exacting expectations of today’s keyboard brands.

Mechanical Keyboard PCB Assembly Process and Quality Standards

Professional Mechanical Keyboard PCB Assembly demands precise control over multiple assembly stages while maintaining consistency across production runs. The comprehensive process for Keyboard Assembly Service includes:

- SMT component placement for PCB Assembly including controllers and passive components

- Through-hole assembly for Switch Soldering Service with consistent joint quality

- Hot-swap socket installation for modular Keyboard Manufacturing designs

- LED placement and testing ensuring uniform backlighting in Turnkey Assembly

- Stabilizer mounting and lubrication for smooth operation

- Firmware flashing and functional testing completing Mechanical Keyboard PCB Assembly

Keyboard Assembly Service operations typically employ combination of SMT assembly for surface components and selective wave or hand soldering for switches. The challenge of PCB Assembly lies in maintaining consistent solder joint quality across hundreds of connections. Switch Soldering Service requires temperature control preventing switch housing damage while ensuring reliable connections.

Advanced Keyboard Manufacturing lines integrate automated optical inspection, in-circuit testing, and custom jigs ensuring every keyboard meets specifications before shipping.

Specialized Assembly Equipment and Techniques

Our assembly capabilities are specifically optimized for the unique requirements of Mechanical Keyboard PCB Assembly and Keyboard Assembly Service:

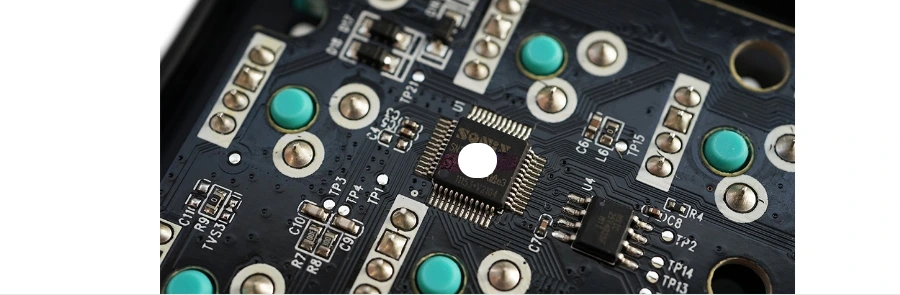

- PCB Assembly: High-speed SMT lines with 0201 component capability

- Switch Soldering Service: Selective soldering systems for precise through-hole assembly

- Keyboard Manufacturing: Custom fixtures ensuring switch alignment during assembly

- Turnkey Assembly: Automated testing equipment validating every key position

- Mechanical Keyboard PCB Assembly: ESD-protected workstations for sensitive components

- Keyboard Assembly Service: Clean room environment preventing contamination

Turnkey assembly services for Mechanical Keyboard PCB Assembly include component sourcing, incoming inspection, and batch traceability. Our Switch Soldering Service maintains precise temperature profiles preventing cold joints while protecting plastic switch housings.

Assembly Workflow and Quality Control for Keyboard Production

Implementing successful keyboard assembly requires systematic workflows, rigorous quality control, and attention to detail ensuring consistent output across production volumes.

Assembly Process Stages

- Pre-Assembly Preparation PCB inspection, component verification, and fixture setup ensuring readiness for production run.

- SMT Component Placement Automated placement of controllers, resistors, capacitors, and other surface-mount components.

- Reflow Soldering Controlled temperature profiles optimized for keyboard PCBs preventing component damage.

- Through-Hole Assembly Switch insertion and soldering using wave, selective, or hand soldering based on volume.

- Secondary Operations Hot-swap socket installation, stabilizer mounting, and any manual assembly requirements.

Quality Assurance Protocols

- Automated Optical Inspection Machine vision systems detecting placement errors, solder defects, and component issues.

- In-Circuit Testing Electrical verification of all connections ensuring proper circuit functionality.

- Functional Testing Every key tested for actuation, with RGB and special features validated.

- Burn-In Testing Extended operation under stress conditions identifying early failures.

Mechanical Keyboard PCB Assembly Applications and Service Levels

Mechanical Keyboard PCB Assembly services support diverse market segments and production requirements:

- Mechanical Keyboard PCB Assembly for Boutique and Custom Builders

- Keyboard Assembly Service for Kickstarter and Crowdfunding Projects

- PCB Assembly for OEM and ODM Keyboard Brands

- Switch Soldering Service for Enthusiast DIY Kits

- Keyboard Manufacturing for Corporate and Enterprise Orders

- Turnkey Assembly for Complete Ready-to-Ship Products

- Rework Services for Defective Board Repair and Modification

Keyboard Assembly Service increasingly includes value-added services like custom packaging, kitting with Mechanical Keyboard PCB Assembly for DIY sales. Our comprehensive PCB Assembly capabilities support everything from bare board assembly to complete product fulfillment.

Integrated Manufacturing Solutions for Keyboard Assembly

Beyond core Mechanical Keyboard PCB Assembly, we provide comprehensive manufacturing solutions:

Component Management:

- Switch sourcing from Cherry, Gateron, Kailh suppliers

- Keycap procurement and matching services

- Stabilizer selection and preparation

- Cable assembly and testing

Value-Added Services:

- Firmware development and customization

- Serial number assignment and tracking

- Custom packaging and branding

- Drop-shipping and fulfillment services

Production Support:

- Design for manufacturing (DFM) consultation

- Prototype assembly for validation

- Small batch runs for market testing

- Scalable production from 100 to 100,000 units

Why Choose HILPCB for Mechanical Keyboard PCB Assembly

At HILPCB, we understand that every keyboard project — whether a custom enthusiast build or a large-scale OEM run — requires the same attention to detail, precision, and quality. Our strength lies in combining advanced PCB manufacturing with dedicated assembly services, ensuring that every mechanical keyboard PCB we produce meets the expectations of both brands and end users.

Beyond keyboards, we also manufacture PCBs for related peripherals such as gaming mice, audio mixers, microphones, and streaming consoles — giving us unique experience in building cohesive ecosystems of gaming and productivity devices. This broader perspective allows us to engineer PCBs that not only perform flawlessly but also integrate seamlessly across product families.

With internationally recognized certifications and a proven track record of delivering both simple and complex boards, we provide customers with the confidence that their projects are in capable hands. From prototypes and small batches to full-scale production, HILPCB ensures stable quality, efficient turnaround, and scalable solutions that let you focus on design innovation while we take care of manufacturing excellence.

Frequently Asked Questions – Mechanical Keyboard PCB Assembly

Q1: What's included in complete Mechanical Keyboard PCB Assembly service?

A: Complete assembly includes PCB fabrication, component sourcing, SMT assembly, switch soldering, testing, firmware installation, and packaging. Turnkey services can also include keycaps, cases, and final packaging.

Q2: How are switches installed during Keyboard Assembly Service?

A: Switches are typically installed using selective wave soldering for volume production, or hand soldering for small batches. Hot-swap sockets are usually SMT components placed during reflow.

Q3: What quality standards apply to PCB Assembly for keyboards?

A: IPC-A-610 Class 2 is standard for commercial keyboards, defining acceptable solder joint quality, component placement, and cleanliness. Gaming and premium keyboards may require Class 3 standards.

Q4: Can Switch Soldering Service handle different switch types?

A: Yes, assembly lines can handle Cherry MX, Gateron, Kailh, and other switch types. Different switches may require adjusted soldering parameters and fixtures for optimal results.

Q5: What's the minimum order quantity for Keyboard Manufacturing?

A: MOQs vary by complexity: prototype assembly can start at 5-10 units, small batch production typically requires 100+ units, while cost-effective mass production starts around 500-1000 units.

Q6: How long does Turnkey Assembly take from order to delivery?

A: Standard lead times are 2-3 weeks for prototypes, 3-4 weeks for small batches, and 4-6 weeks for volume production. This includes PCB fabrication, component sourcing, assembly, and testing.