As healthcare becomes more digital, precise, and connected, Medical PCBs play an essential role in nearly every class of modern medical equipment. From diagnostic imaging to wearable health monitors, printed circuit boards are the heart of today’s life-saving innovations.

At Highleap PCB, we manufacture and assemble medical-grade PCBs under strict quality control and ISO-compatible processes. Our solutions serve regulated applications including implantable devices, imaging equipment, and mobile care electronics.

Medical PCBs are fundamental in medical robotics, where precision motion control and feedback are essential. Robotic-assisted surgery systems, for example, use sensor-rich PCBs to translate a surgeon’s hand movements into micromovements of surgical instruments. These boards must respond with ultra-low latency and be shielded against electromagnetic interference that could affect surgical accuracy.

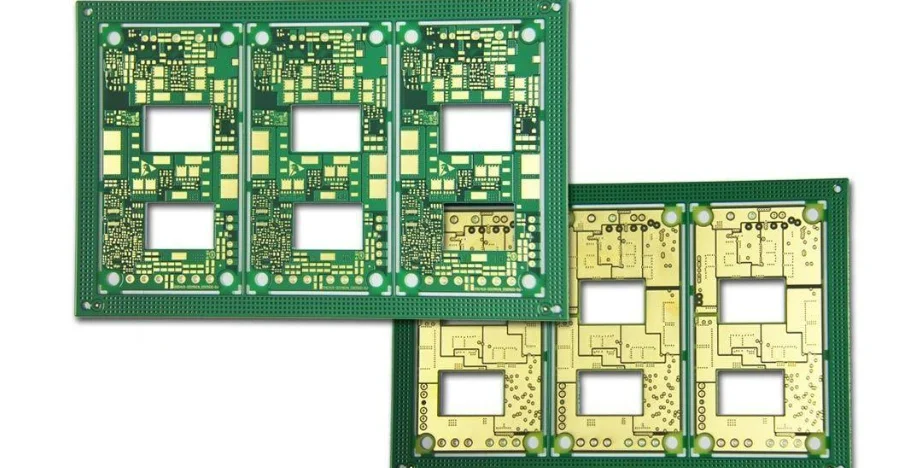

What Is a Medical PCB?

In laboratories, PCBs play a silent but critical role in devices like centrifuges, pipetting robots, and DNA sequencing equipment. These instruments demand repeatable control and reliable power delivery, often in thermally challenging environments. High-grade materials, gold-plated finishes for oxidation resistance, and conformal coatings to withstand moisture and reagent exposure are vital.

A Medical PCB is a printed circuit board engineered for use in medical devices. These boards must meet strict safety, reliability, and cleanliness standards. Unlike consumer electronics, medical PCBs are often used in devices that monitor vital signs, deliver therapy, or support life-critical functions—meaning performance failures are not an option.

Medical PCBs are typically:

- Miniaturized for portable and implantable designs

- Built to IPC Class 3 or ISO 13485 manufacturing standards

- Assembled in controlled environments with clean packaging

- Designed with EMI shielding and thermal reliability

When designing a PCB for medical use, engineers must account for long product life cycles, compatibility with sterilization methods (autoclave, ETO, gamma), and robust traceability mechanisms. Highleap offers serialization, barcode traceability, and part-level lot tracking for full transparency and compliance throughout manufacturing.

Common Applications of Medical PCBs

The demand for PCB assembly in medical devices spans across several fast-growing categories:

Medical electronics are becoming software-defined and cloud-connected, but the foundation remains a robust physical layer—the PCB. Real-time monitoring, device automation, and miniaturized diagnostics all depend on PCB integrity.

1. Medical Imaging Equipment

PCBs in imaging systems must handle high-speed data, analog-to-digital conversion, and precise timing:

- MRI scanner signal boards

- CT and PET data acquisition modules

- Ultrasound transducer arrays

- Digital X-ray and fluoroscopy control PCBs

2. Patient Monitoring Devices

PCBs for monitoring systems must support wireless transmission, long battery life, and biocompatible interfaces:

- ECG/EKG boards

- Blood glucose and pressure monitors

- Respiratory rate sensors

- Multi-parameter telemetry modules

3. Wearable & Portable Medical Devices

Wearable PCBs must be flexible, ultra-compact, and able to withstand daily use:

- Fitness trackers with medical accuracy

- Wireless patches and biosensor PCBs

- Smart infusion pumps

- Real-time temperature or hydration monitors

4. Implantable Medical Electronics

Implantable PCBs are often custom-built and require extreme miniaturization and reliability:

- Cochlear implants

- Implantable cardioverter-defibrillators (ICDs)

- Responsive neurostimulation (RNS) systems

- Deep brain stimulation (DBS) devices

Key PCB Technologies for Medical Electronics

At Highleap, we provide advanced technologies to meet the requirements of modern healthcare systems:

- SMT Medical PCB Assembly for compact, high-density boards

- Flexible and Rigid-Flex PCB Fabrication for wearable and implantable use

- HDI and Microvia Boards for signal integrity and miniaturization

- Controlled Impedance Routing for RF and analog applications (calculate impedance)

- Conformal Coating and Cleaning for sterilization and bio-compatibility

Use our online Gerber Viewer to inspect your medical PCB layout before manufacturing.

Why Choose Highleap for Medical PCB Manufacturing?

We understand the challenges of manufacturing for regulated medical environments. Whether you're building a low-volume clinical prototype or scaling to volume, Highleap offers:

- ISO-compatible manufacturing processes

- IPC Class 3 and FDA-oriented QA standards

- Traceability and cleanroom-compliant packaging

- High-mix, low-volume flexibility

- Speedy prototyping and stable mass production

We work with diagnostic OEMs, wearable healthcare innovators, and device startups bringing new solutions to the global medical market.

Medical PCBs for Consumer and Home Healthcare Devices

Medical-grade PCBs are no longer exclusive to hospitals or clinical-grade machines. Today’s healthcare ecosystem includes a growing array of consumer health electronics, smart home medical devices, and assistive peripheral systems, all powered by compact, energy-efficient printed circuit boards.

Home Diagnostic Devices

Devices such as digital thermometers, blood pressure monitors, pulse oximeters, and glucometers now feature microcontroller-based PCBs with wireless communication modules. These enable patients to record health metrics at home and share them with caregivers or telemedicine platforms. Highleap manufactures low-power, compact PCBs tailored for battery operation and data security in home-use devices.

Portable Therapy Equipment

Modern physical therapy and pain relief devices—like TENS units, EMS muscle stimulators, and portable nebulizers—rely on PCBs designed for motion tolerance, efficient signal transmission, and minimal form factor. Our rigid-flex and SMT PCB assemblies are ideal for such wearables and handheld therapies.

Smart Medication Dispensers and Reminders

Medication adherence technologies, including automatic pill organizers, reminder systems, and dosage verification devices, depend on intelligent PCBs with sensors, timers, and communication capabilities. Highleap produces boards for smart pill boxes with Bluetooth syncing, voice alerts, and integrated app control.

Assistive and Daily Living Devices

Medical PCBs are also used in devices that support mobility and independence, such as electronic canes, posture trainers, digital hearing aids, and fall-detection alarms. These applications require energy-efficient PCBs with high integration and user-friendly interfaces.

By expanding into consumer and home-use categories, the role of the medical PCB has grown from clinical infrastructure to personal health empowerment—without compromising quality or safety.

Start Your Medical PCB Project with Confidence

At Highleap, we not only deliver PCBs—we collaborate with R&D teams, compliance engineers, and medical innovators globally, becoming your PCB engineering partner in healthcare innovation.

Whether you're building imaging systems, biosensor patches, or Class II medical monitors, Highleap is ready to deliver certified PCB fabrication and assembly that meets the demands of modern healthcare.