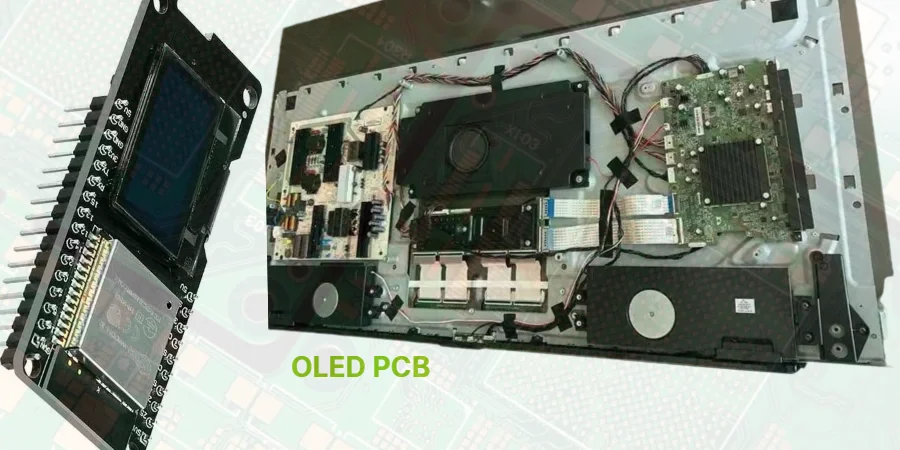

OLED displays represent the pinnacle of display technology - perfect blacks, infinite contrast, and ultra-thin profiles. But the real engineering challenge lies in the OLED PCB that controls every pixel with microscopic precision while managing complex power requirements and thermal constraints.

HILPCB specializes in OLED PCB manufacturing for premium smartphones, automotive displays, flexible screens, and professional monitors. Our advanced manufacturing processes handle the unique requirements of organic light-emitting diode technology, from precise current control to ultra-thin flexible circuits.

Modern OLED PCB designs integrate sophisticated power management, timing controllers, and driver circuits within extremely compact form factors. Our expertise encompasses rigid OLED controllers, flexible OLED assemblies, and cutting-edge foldable display systems supporting the latest OLED innovations.

OLED PCB Architecture and Current Control Systems

OLED PCB design requires exceptional precision in current control and power management. Unlike LCD displays that manipulate existing light, OLED pixels generate their own illumination, creating unique electrical requirements that demand specialized PCB architectures.

Core OLED PCB Components:

• Precision Current Drivers: Individual pixel current control circuits maintaining ±1% accuracy across millions of pixels with temperature compensation and aging correction algorithms

• Multi-Rail Power Management: Complex power systems delivering 5-7 different voltage levels from 1.8V logic supplies to 15V pixel drivers with ultra-low noise characteristics

• Advanced Timing Controllers: High-speed processors managing pixel data, refresh rates up to 120Hz, and sophisticated image processing algorithms for optimal OLED performance

• Thermal Management Integration: Specialized heat dissipation systems protecting organic compounds from thermal degradation while maintaining electrical performance

OLED pixels require precise current regulation rather than voltage control, with variations of just 1% causing visible brightness differences. Our OLED PCB designs implement advanced current-mode drivers with real-time feedback control ensuring consistent performance across temperature variations and component aging.

We manufacture complete OLED display ecosystems including OLED display driver boards, flexible OLED PCB assemblies, OLED backplane controllers, touch-integrated OLED systems, micro-OLED driver circuits for AR/VR applications, and OLED lighting control boards for automotive and architectural applications.

Advanced OLED PCB Manufacturing Technologies

Professional OLED PCB manufacturing employs cutting-edge fabrication techniques optimized for ultra-thin designs, flexible applications, and high-density component integration. Material selection and process control directly impact OLED display performance, flexibility, and operational lifespan.

Ultra-Thin PCB Construction:

OLED applications often require PCB thickness below 0.2mm for smartphone integration and flexible display systems. Our specialized manufacturing processes achieve controlled thickness tolerances while maintaining electrical performance and mechanical reliability.

Flexible OLED PCB Solutions:

Flex PCB technology enables curved displays, foldable smartphones, and wearable applications. Polyimide substrates with specialized adhesives support bend radii down to 1mm with validated performance over 100,000+ fold cycles.

High-Density Interconnect Construction:

• Microvias and Sequential Lamination: HDI PCB construction with via-in-pad technology supporting fine-pitch OLED controller ICs down to 0.3mm pitch

• Advanced Layer Stack-ups: Optimized dielectric materials and layer arrangements for high-speed digital signals and precise analog performance

• Thermal Interface Integration: Direct copper bonding and thermal vias connecting OLED drivers to heat spreaders and cooling systems

• Moisture Protection: Specialized coatings and hermetic sealing techniques protecting OLED circuits from environmental degradation

Precision OLED PCB Assembly and Quality Control

OLED PCB assembly demands exceptional precision and cleanliness due to the sensitive nature of organic compounds and fine-pitch component requirements. Our assembly processes ensure optimal electrical performance while preventing contamination that could affect OLED longevity.

Critical Assembly Requirements:

OLED controller ICs utilize advanced packaging including ultra-fine-pitch BGA and wafer-level chip-scale packages requiring specialized SMT assembly capabilities. Placement accuracy within ±15 μm ensures reliable connections while preventing mechanical stress on sensitive components.

OLED PCB Application Categories:

• Smartphone OLED PCBs: Ultra-compact designs supporting always-on displays, high refresh rates, and integrated touch functionality with optimized power efficiency

• Automotive OLED Controllers: Qualified designs meeting AEC-Q100 standards for dashboard displays, lighting systems, and advanced HMI applications

• Flexible OLED Assemblies: Specialized flex circuits for curved displays, foldable devices, and wearable applications with mechanical reliability validation

• Professional OLED Systems: High-performance controllers for medical imaging, professional monitors, and broadcast applications requiring exceptional color accuracy

Advanced Assembly Processes:

Cleanroom assembly environments prevent particle contamination affecting OLED performance. Nitrogen atmosphere reflow and specialized flux formulations minimize thermal stress while ensuring reliable solder joint formation across mixed component types.

OLED PCB Applications and Design Optimization

HILPCB delivers OLED PCB manufacturing solutions for premium consumer electronics, automotive systems, medical devices, and emerging applications, ensuring optimal performance and scalable production from prototype through high-volume manufacturing.

Consumer Electronics Leadership: Smartphone OLED PCBs supporting flagship devices with advanced features including under-display fingerprint sensors, high refresh rate displays, and power-efficient always-on functionality. Recent projects include foldable display controllers and ultra-thin wearable OLED systems.

Automotive OLED Innovation: Dashboard displays, ambient lighting systems, and advanced instrument clusters meeting automotive environmental and reliability standards. Enhanced EMC performance and temperature cycling validation for reliable vehicle integration.

Medical and Professional Applications: High-precision OLED controllers for medical imaging devices, professional photo editing monitors, and broadcast equipment requiring exceptional color accuracy and regulatory compliance including FDA and CE medical standards.

Emerging OLED Technologies: Transparent OLED controllers, micro-OLED drivers for augmented reality applications, and large-format OLED display systems representing next-generation visual technology applications.

Professional OLED PCB Manufacturing Services

At HILPCB, we deliver comprehensive OLED PCB manufacturing and assembly solutions, accelerating your product development from concept through mass production. Our expertise in precision assembly, flexible circuits, and thermal management ensures reliable OLED performance and competitive time-to-market.

Technical Excellence:

- Advanced Manufacturing: Ultra-thin PCBs, flexible constructions, and HDI technology supporting the most demanding OLED applications

- Quality Assurance: ISO 9001:2015 certified with specialized OLED testing including current uniformity measurement and thermal cycling validation

- Rapid Development: 5-7 day prototype delivery with comprehensive engineering support and design optimization services

- Global Standards: RoHS and REACH compliance with complete material traceability and regulatory documentation

Strategic Advantages: Our Shenzhen facility provides access to advanced PCB materials, specialized OLED components, and precision manufacturing equipment suppliers, enabling rapid adoption of emerging OLED technologies and cost optimization through efficient supply chains while maintaining international quality standards.

Frequently Asked Questions About OLED PCB Manufacturing

Q: Can Chinese manufacturers handle advanced OLED PCB requirements? A: Leading Chinese manufacturers have invested heavily in OLED-specific equipment and expertise. We work directly with OLED panel manufacturers and use the same assembly equipment as global facilities while offering significant cost advantages.

Q: How do you ensure quality for flexible OLED PCBs? A: We maintain specialized flex testing equipment including bend testers and environmental chambers. All flexible OLED PCBs undergo mechanical cycling validation and electrical performance verification across temperature ranges.

Q: What's the typical lead time for OLED PCB prototypes? A: Standard OLED PCB prototypes are delivered within 5-7 days with express 3-day service available. Our local component sourcing and streamlined processes enable faster turnaround than most alternatives.

Q: Do you support both rigid and flexible OLED applications? A: Yes, we manufacture the complete range from rigid smartphone controllers to ultra-thin flexible circuits for foldable displays. Our capabilities include polyimide substrates, specialized adhesives, and mechanical reliability testing.

Q: How do you handle the complexity of OLED power management? A: Our power engineering team has specific OLED experience including multi-rail power systems, current regulation circuits, and thermal management. We provide power simulation and optimization services for complex OLED applications.