PCB (Printed Circuit Board) manufacturing is the foundation of modern electronics. Understanding the basic processes and quality standards is essential for anyone working in electronics design and manufacturing.

What is PCB Manufacturing?

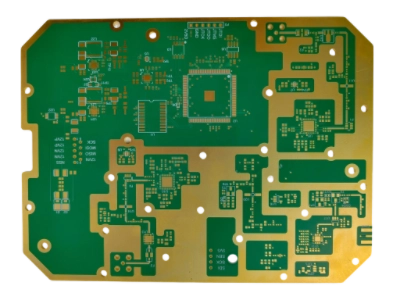

PCB manufacturing is the process of creating printed circuit boards that serve as the backbone for electronic devices. These boards provide both mechanical support and electrical connections for electronic components.

Key Components of a PCB

- Substrate: The base material, typically FR4 fiberglass

- Copper Layers: Conductive pathways for electrical signals

- Solder Mask: Protective coating, usually green

- Silkscreen: Component labels and markings

Manufacturing Process Overview

1. Design and Planning

The manufacturing process begins with the PCB design files, typically in Gerber format. Our engineering team reviews these files for manufacturability and optimization.

2. Material Preparation

We select high-quality materials based on the application requirements:

- Standard PCBs: FR4 substrate with copper cladding

- High-frequency applications: Rogers or PTFE materials

- Flexible PCBs: Polyimide substrates

3. Layer Stackup

For multilayer boards, we carefully plan the layer stackup to ensure:

- Proper impedance control

- Minimal signal interference

- Optimal thermal management

4. Drilling and Plating

Precision drilling creates holes for component mounting and via connections. Through-hole plating ensures reliable electrical connections between layers.

Quality Control Standards

IPC Standards Compliance

We adhere to international IPC standards:

- IPC-A-600: Acceptability of Printed Boards

- IPC-6012: Qualification and Performance Specification

- IPC-A-610: Acceptability of Electronic Assemblies

Testing Procedures

Every PCB undergoes comprehensive testing:

- Electrical Testing: Continuity and isolation tests

- Visual Inspection: Automated Optical Inspection (AOI)

- Dimensional Verification: Precise measurement of critical dimensions

Advanced Manufacturing Capabilities

HDI (High Density Interconnect)

For compact designs requiring:

- Microvias (≤150μm diameter)

- Fine pitch components

- Multiple lamination cycles

Rigid-Flex PCBs

Combining rigid and flexible sections for:

- Space-constrained applications

- Improved reliability

- Reduced assembly complexity

Material Specifications

| Parameter | Standard Range | High-Performance |

|---|---|---|

| Copper Weight | 1-2 oz | 3-6 oz |

| Min Trace Width | 0.1mm | 0.075mm |

| Min Via Size | 0.2mm | 0.1mm |

| Layer Count | 1-16 | 18-32 |

Environmental Considerations

RoHS Compliance

All our manufacturing processes comply with RoHS (Restriction of Hazardous Substances) directive, ensuring:

- Lead-free soldering processes

- Elimination of hazardous materials

- Environmental sustainability

Waste Management

We implement comprehensive waste management:

- Chemical recycling programs

- Copper recovery systems

- Minimal environmental impact

Applications and Industries

Our PCB manufacturing serves diverse industries:

- Consumer Electronics: Smartphones, tablets, laptops

- Automotive: ECUs, sensors, infotainment systems

- Medical Devices: Diagnostic equipment, implantable devices

- Industrial: Control systems, automation equipment

- Telecommunications: 5G infrastructure, networking equipment

Quality Assurance Process

Incoming Material Inspection

- 100% material verification

- Supplier certification review

- Material traceability documentation

In-Process Quality Control

- Real-time process monitoring

- Statistical process control (SPC)

- Immediate corrective actions

Final Inspection

- Comprehensive electrical testing

- Visual inspection with AOI

- Packaging and shipping verification

Conclusion

PCB manufacturing combines precision engineering with advanced technology to create the foundation of modern electronics. At Highleap PCB, we're committed to delivering high-quality boards that meet the most demanding specifications.

Our investment in state-of-the-art equipment, rigorous quality control, and continuous improvement ensures that every PCB meets or exceeds customer expectations.

Contact our technical team for more information about our PCB manufacturing capabilities and how we can support your next project.