Highleap PCB Factory offers comprehensive turnkey PCBA (Printed Circuit Board Assembly) services that cover every stage of the electronics manufacturing process. From bare‑board fabrication to final functional testing, our fully integrated facility helps you reduce complexity, shorten lead‑times, and boost product quality.

Our capabilities support everything from early‑stage prototypes to mass production, delivering flexibility and reliability at the heart of every build.

PCB Manufacturing Capabilities

High‑quality PCB fabrication is the cornerstone of reliable electronics. Highleap operates advanced in‑house production lines capable of manufacturing a vast range of board types.

- Materials: standard FR‑4, high‑TG laminates for high‑temperature environments, Rogers and PTFE for RF designs, plus aluminum or copper core for power and LED products.

- Layer counts: single‑ and double‑sided boards up to 60‑layer multilayers, with blind/buried vias if required.

- Finishes: leaded or lead‑free HASL, ENIG for high reliability, OSP for RoHS‑friendly builds, immersion silver or gold for high‑speed circuits.

- Optional services: controlled impedance, custom stack‑ups, panelisation, tight‑tolerance drilling.

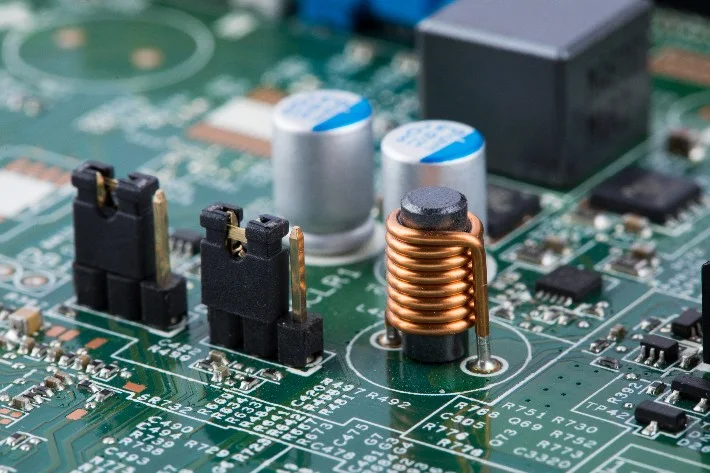

PCB Assembly Services

Our SMT and THT lines run inside ESD‑safe environments and place all common package sizes:

- Devices down to 0201 / 01005, plus fine‑pitch ICs, BGAs, QFNs, LGAs and CSPs.

- Mixed‑technology builds and double‑sided reflow.

- Lead‑free, RoHS‑compliant soldering, with wave or selective solder for through‑hole parts.

- Auxiliary processes such as glue dispensing, under‑fill, conformal coating, potting and post‑wash cleaning.

Typical placement speed exceeds 250 000 components per hour with ±30 µm accuracy, guaranteeing both throughput and precision.

Component Sourcing and BOM Management

As part of our turnkey PCBA service, Highleap sources components exclusively through authorised distributors — Digikey, Mouser, Arrow, Avnet, Future Electronics and direct OEM channels.

- BOM risk analysis flags EOL or allocation issues early and recommends drop‑in replacements.

- Every lot is 100 % traceable with anti‑counterfeit inspection, date‑code and lot tracking.

- Our engineers optimise your BOM to balance cost, availability and automated assembly compatibility.

Quality Control and Functional Testing

Each assembly passes a stringent, multi‑stage quality programme:

- 3D Automated Optical Inspection (AOI) after both reflow and wave processes.

- X‑ray inspection for hidden joints on BGAs, LGAs and power modules.

- In‑Circuit Test (ICT) plus customer‑specific Functional Circuit Test (FCT).

- Optional burn‑in, temperature cycling and mechanical stress tests for mission‑critical products.

All inspection reports are archived and delivered on request.

Scalability and Flexible Production

- Prototypes from just five units, shipped in as little as five to seven business days.

- Pilot runs of 100–1 000 pieces for design validation and certification.

- Mass production exceeding 100 000 boards per month with JIT or Kanban logistics.

Our integrated workflow lets you scale quickly, implement design changes without delay and keep total cost of ownership low.

A Complete Manufacturing Partner

Highleap’s turnkey PCBA service offers more than assembly lines: we provide experienced engineering support, robust supply‑chain management and rigorous quality control — everything needed to move your product from concept to market with confidence.

Send us your Gerber files and BOM for a fast, detailed quotation and let Highleap PCB Factory become your trusted partner in PCBA manufacturing.