The Mars rover Perseverance contains over 100 specialized PCBs working in perfect harmony to enable autonomous navigation, scientific analysis, and communication across 140 million miles of space. Each PCB represents years of engineering refinement, incorporating AI processors, precision sensors, and radiation-hardened components that function flawlessly in an environment where repair is impossible.

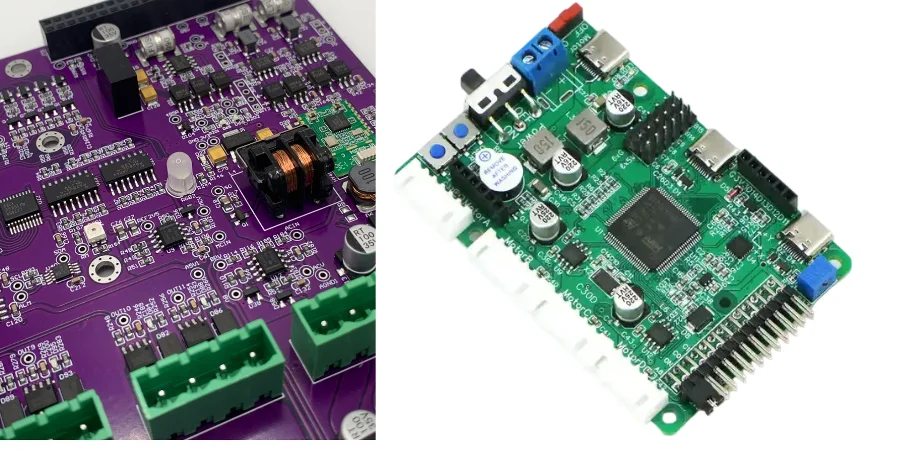

While most robotics PCBs won't face Martian conditions, they share similar design challenges: integrating complex processing capabilities, managing multiple sensor inputs, controlling precise actuators, and operating reliably in demanding environments. At Highleap PCB Factory (HILPCB), we've developed expertise in creating the sophisticated PCB systems that form the electronic nervous system of modern robots.

From simple hobby robots to industrial automation systems, successful robotics PCB design requires careful integration of AI processing, sensor fusion, motor control, and power management—all while achieving the size, weight, and cost targets that make robotic systems practical.

AI Processing and Central Control Units

Modern robots increasingly rely on artificial intelligence for autonomous decision-making, requiring PCB designs that support powerful processors while managing thermal and power constraints in mobile platforms.

Edge AI Processor Integration: Contemporary robotics applications use dedicated AI processors like NVIDIA Jetson modules or specialized neural processing units. These high-performance processors generate significant heat while requiring complex power sequencing and high-speed memory interfaces. High thermal conductivity PCB designs become essential for managing thermal loads while maintaining processing performance.

Multi-Core ARM Processor Systems: Robotics control systems often use ARM Cortex-A series processors that handle real-time control algorithms alongside high-level decision making. PCB design must support high-speed DDR memory interfaces, multiple communication protocols, and real-time I/O processing. Signal integrity becomes critical for maintaining system stability during intensive computational tasks.

FPGA-Based Processing: Field Programmable Gate Arrays provide hardware acceleration for sensor processing and motor control algorithms. FPGA PCB design requires careful power distribution and high-speed differential signaling for maximum performance. Configuration memory and programming interfaces must be accessible while maintaining system security.

Distributed Processing Architecture: Complex robots often use multiple processing units distributed throughout the system. A central control PCB coordinates with specialized processor boards for vision, motion control, and sensor processing. Inter-processor communication requires robust networking capabilities and standardized interfaces.

Memory and Storage Systems: AI applications require substantial memory for neural networks and data storage for sensor logs. High-speed memory interfaces demand precise signal routing and power delivery. HDI PCB technology enables dense memory integration while maintaining signal integrity for high-bandwidth applications.

Sensor Integration and Data Acquisition

Robotic systems depend on multiple sensor types for environmental awareness, requiring PCB designs that handle diverse signal types while maintaining accuracy and noise immunity.

Vision System Integration: Cameras provide primary environmental sensing for most autonomous robots. PCB design must support high-speed MIPI CSI interfaces for camera connections while managing the substantial data bandwidth required for real-time image processing. Multiple camera inputs require careful routing to prevent crosstalk and maintain image quality.

LiDAR and Range Sensor Interfaces: 3D mapping sensors generate massive amounts of data requiring high-speed interfaces and substantial processing power. PCB design must accommodate the power requirements and heat generation of spinning LiDAR units while providing vibration isolation for precision measurements.

IMU and Motion Sensing: Inertial measurement units provide critical orientation and acceleration data for robot navigation. Precision analog circuits condition accelerometer and gyroscope signals while digital interfaces handle magnetometer data. PCB layout must minimize vibration coupling and electromagnetic interference that could affect measurement accuracy.

Environmental Sensor Arrays: Temperature, humidity, pressure, and gas sensors provide environmental awareness for robots operating in varying conditions. Mixed-signal PCB design techniques isolate sensitive analog circuits from digital noise while providing appropriate excitation and measurement circuits for different sensor types.

Ultrasonic and Proximity Detection: Short-range sensing uses ultrasonic transducers and infrared sensors for obstacle detection and proximity awareness. PCB design must handle high-voltage drive signals for ultrasonic transducers while providing precise timing measurement for distance calculations.

Motor Control and Actuation Systems

Robotic movement depends on precise motor control systems that manage everything from fine positioning to high-torque drive applications, requiring PCB designs optimized for power efficiency and control accuracy.

Servo Motor Control Circuits: Precision positioning applications use servo motors with encoder feedback for closed-loop control. PCB design must support high-resolution encoder interfaces while providing smooth PWM control signals. Current sensing circuits enable torque control and overload protection for delicate manipulation tasks.

Stepper Motor Drive Electronics: Many robots use stepper motors for precise positioning without requiring encoder feedback. Stepper driver PCBs must generate precisely timed drive pulses while handling significant current levels. Heavy copper PCB construction helps manage the thermal loads from high-current motor drives.

BLDC Motor Control: Brushless DC motors provide efficient high-speed operation for robot mobility and tools. Three-phase inverter circuits require sophisticated control algorithms and precise timing. Gate driver circuits must provide isolated drive signals while maintaining fast switching speeds for optimal efficiency.

Linear Actuator Interfaces: Many robotic applications require linear motion for gripping, lifting, or positioning tasks. Linear actuator control PCBs integrate H-bridge drive circuits with position feedback systems. Safety interlocks prevent overextension or excessive force that could damage the robot or surrounding equipment.

Hydraulic and Pneumatic Control: Heavy-duty robots often use hydraulic or pneumatic actuators for high-force applications. Control PCBs interface with proportional valves and pressure sensors while providing safety shutdown capability. Harsh industrial environments require robust PCB protection and reliable operation over extended periods.

Power Management and Battery Systems

Mobile robots face unique power management challenges, requiring PCB designs that maximize battery life while providing stable power for varying computational and motor loads.

Multi-Rail Power Distribution: Robotics systems typically require multiple voltage levels for different subsystems. Switching regulators provide efficient power conversion while linear regulators supply clean power for sensitive analog circuits. Power sequencing ensures proper startup and shutdown procedures that protect system integrity.

Battery Management Systems: Lithium-ion battery packs require sophisticated monitoring and protection circuits to prevent overcharge, over-discharge, and thermal runaway conditions. Battery management PCBs monitor cell voltages, temperatures, and current flow while providing balancing circuits for optimal pack performance and longevity.

Motor Drive Power Electronics: High-current motor drives create challenging power management requirements with rapidly varying loads. Large filter capacitors smooth power delivery while current limiting circuits protect against fault conditions. Regenerative braking systems can recover energy during deceleration, requiring bidirectional power flow capability.

Wireless Charging Integration: Some robotic systems incorporate wireless charging capability for autonomous operation. Wireless power receiver circuits must integrate with existing power management while providing foreign object detection and safety shutdown capability.

Power Monitoring and Optimization: Advanced robotics systems monitor power consumption in real-time to optimize battery life and predict maintenance requirements. Current sensing circuits and power monitoring ICs provide detailed consumption data while enabling adaptive power management strategies.

Communication and Networking Interfaces

Modern robots require advanced communication systems for efficient operation, data sharing, and integration with larger automation ecosystems.

- Wireless Communication: WiFi, Bluetooth, and cellular networks enable remote control, telemetry, and real-time data transmission. Effective antenna placement and RF circuit design are essential for maintaining reliable communication while robots move through dynamic environments. Rogers PCB materials ensure optimal RF performance for wireless circuits, enhancing reliability and range.

- Industrial Network Integration: Factory robots must seamlessly integrate with industrial communication protocols like EtherCAT, PROFINET, and Modbus. These protocols allow robots to communicate efficiently with manufacturing systems, requiring precise timing, high-speed data exchange, and deterministic message delivery for synchronized operations.

- Inter-Robot Communication: In swarm robotics, multiple robots coordinate through mesh networking and low-latency communication protocols. This allows for synchronized, real-time interaction and task sharing, ensuring effective collaboration between autonomous units in large-scale operations.

- Safety Communication Systems: Critical applications, such as emergency stop signals or fault reporting, rely on redundant communication channels and safety-rated protocols (e.g., SIL, PLe). These systems ensure that vital information is transmitted reliably, even when primary communication systems fail, preventing system-wide downtime and ensuring operational safety.

- Edge and Cloud Communication: Robots may also communicate with central cloud systems for remote monitoring, predictive maintenance, and data logging. Real-time edge processing allows for quick local decision-making, while cloud-based analytics can be used for long-term system optimization and performance tracking.

These advanced communication and networking interfaces are fundamental to modern robotics, enabling complex tasks and reliable interaction within both isolated and interconnected automated environments.

Miniaturization and Advanced PCB Technologies

In robotics, size and weight constraints drive the need for advanced PCBs that maximize functionality in a compact form.

- Rigid-Flex PCB Solutions: Rigid-flex PCBs eliminate connectors and accommodate robot joint movement while ensuring durability and electrical integrity over millions of flex cycles.

- 3D PCB Integration: 3D PCB assemblies optimize space within the robot chassis, offering high-density processing and efficient thermal management.

- Embedded Component Technology: Embedded resistors and capacitors reduce surface area, improving signal integrity and thermal management.

- Micro-Robot PCB Design: Compact robotic systems use multi-function ICs and system-on-chip solutions to combine processing, communication, and control on a single board.

Our turnkey assembly services streamline sourcing and assembly, with simulation tools ensuring optimal performance before prototyping.

Frequently Asked Questions

Q: What processing power is needed for AI-enabled robotics PCBs? Requirements vary from simple microcontrollers for basic tasks to powerful GPU-accelerated processors for computer vision and machine learning. Edge AI processors like NVIDIA Jetson provide good balance of performance and power efficiency.

Q: How do you handle EMI in robotics PCBs with multiple wireless systems? Use proper shielding techniques, frequency coordination between wireless systems, filtered power supplies, and careful antenna placement to minimize interference. RF circuit isolation becomes critical in multi-radio designs.

Q: What's the biggest challenge in robotics PCB thermal management? Managing heat from high-performance processors and motor drives in space-constrained mobile platforms. Advanced thermal design includes heat spreading, thermal vias, and sometimes active cooling integration.

Q: How important is power efficiency in robotics PCB design? Critical for mobile robots where battery life directly affects operational capability. Efficient switching regulators, sleep mode implementation, and adaptive power management significantly extend operating time.

Q: Can robotics PCBs be repaired in the field? Design for serviceability includes modular construction, accessible test points, and replaceable components. However, complex integration often requires factory-level repair capabilities for sophisticated robotics systems.