In mission-critical satellite and aerospace systems, every component’s reliability matters. For satellite PTFE PCBs, signal integrity, thermal stability, and performance under extreme conditions define mission success. Selecting the right manufacturer isn’t just a transaction-it’s a strategic partnership that minimizes risk and ensures consistent results.

Our approach is built on three pillars: Uncompromising Quality, On-Time Delivery, and Proactive Engineering Support.

1. Uncompromising Quality for High-Frequency PTFE PCBs

PTFE’s performance depends on precise fabrication and strict quality control. Our AS9100D-certified systems and specialized processes guarantee boards meet stringent aerospace requirements.

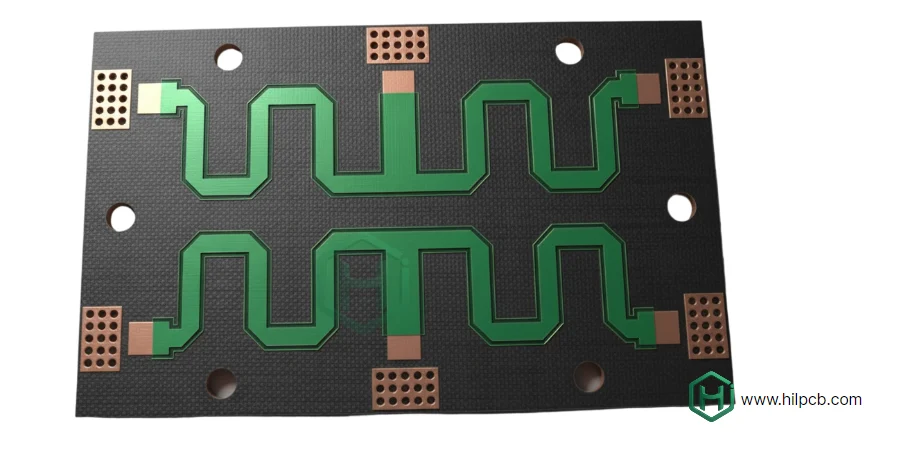

- Advanced PTFE Fabrication: Plasma treatment enhances layer adhesion, precision-controlled drilling ensures via reliability, and vacuum lamination eliminates voids-critical for space-grade PCBs.

- Data-Driven Validation: Every batch undergoes TDR (Time Domain Reflectometry) and VNA (Vector Network Analyzer) testing to verify impedance and signal loss. Detailed reports provide measurable proof that boards meet specifications.

- Full Aerospace Traceability: From raw material lot numbers to final inspection reports, we provide complete documentation for regulatory compliance and total supply chain transparency.

2. On-Time Delivery with Transparent Project Management

In aerospace projects, delays are costly. Our project management ensures satellite PTFE PCB delivery schedules are consistently met.

- Dedicated Project Ownership: A single point of contact manages your project from RFQ through shipment, ensuring accountability and clear communication.

- Real-Time Collaboration: Dedicated Teams, Slack, or WhatsApp channels connect your engineers with our technical team for instant updates and problem-solving.

- Proactive Status Reporting: You’ll never have to chase updates; regular progress reports keep your team informed at every stage.

3. Engineering Support as an Extension of Your Team

We bridge design and manufacturing, ensuring your boards are optimized for both electrical performance and manufacturability.

- Proactive DFM & DFA Review: Early-stage Design-for-Manufacturability (DFM) and Design-for-Assembly (DFA) reviews identify risks, prevent costly delays, and ensure robust final products.

- Expert High-Frequency Consultation: Our engineers provide guidance on stack-ups, trace geometries, and impedance control to meet RF and microwave design requirements.

4. Streamlined Supply Chain: PCB & Assembly Services

Multiple vendors increase risk and complexity. We offer a single-source solution for satellite projects.

- Comprehensive PCB Capabilities: In addition to satellite PTFE PCBs, we produce FR-4 boards, rigid-flex, and complex hybrid stack-ups.

- Turnkey PCBA Services: From component sourcing to SMT assembly, integration, and final testing, we deliver mission-ready products.

Benefits of this integrated approach:

- Consolidated procurement with a single accountable partner.

- Accelerated project timelines by eliminating handoff delays.

- End-to-end responsibility for quality and delivery.

Conclusion: Partner, Don’t Just Purchase

For mission-critical satellite and aerospace applications, reliability, performance, and delivery certainty are non-negotiable. By partnering with us, you gain more than a supplier-you gain a trusted manufacturing partner dedicated to your project’s success.

We provide comprehensive PCB solutions to support every part of your system. Beyond high-performance satellite PTFE PCBs, we can deliver:

- FR-4 and High-Tg Control Boards for digital and analog circuits

- Rigid-Flex and Flexible PCBs for compact, weight-sensitive modules

- Hybrid Stack-Ups combining multiple materials for mixed-signal systems

- Turnkey PCBA including component sourcing, SMT assembly, integration, and functional testing

This full-spectrum capability ensures you can consolidate procurement, streamline supply chains, and guarantee end-to-end reliability across your entire satellite or aerospace project. With us, every board-from high-frequency PTFE to complex hybrid designs-meets exacting quality standards and is delivered on schedule.

Ready to partner with a trusted manufacturer?