Surface Mount Technology (SMT) assembly has revolutionized electronics manufacturing, enabling the production of compact, high-performance electronic devices. Achieving zero-defect production requires a systematic approach to process optimization, quality control, and continuous improvement.

SMT Process Overview

Key Process Steps

- Solder Paste Printing

- Component Placement

- Reflow Soldering

- Inspection and Testing

- Rework and Repair

Solder Paste Printing Optimization

Stencil Design Considerations

- Aperture ratio: 0.66 for optimal paste release

- Stencil thickness: 100-150μm for fine pitch components

- Aperture shape: Rounded rectangles for improved release

- Step stencils: For mixed component heights

Printing Parameters

Squeegee Speed: 10-25 mm/sec

Squeegee Pressure: 2-4 kg/cm

Separation Speed: 0.1-3.0 mm/sec

Print Gap: 0-0.1mm (contact printing)

Paste Volume Control

- Target volume: 50-80% of pad area × stencil thickness

- Volume consistency: ±10% across the board

- Paste height: 75-125% of stencil thickness

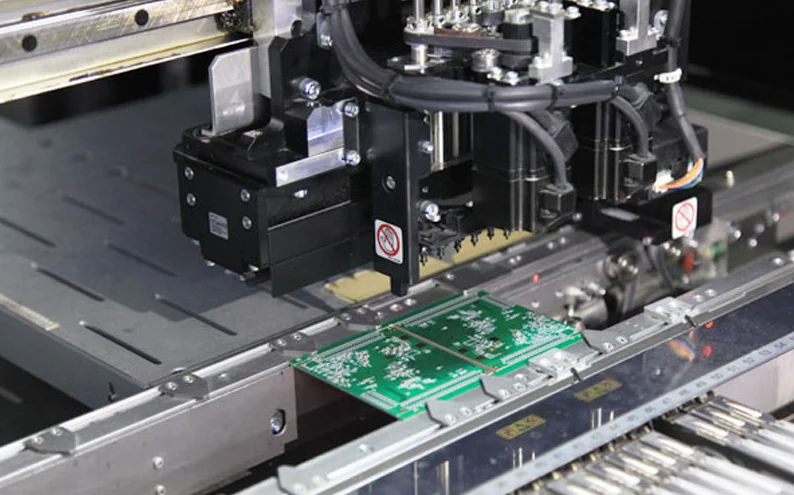

Component Placement Excellence

Placement Accuracy Requirements

- Fine pitch components: ±25μm (3σ)

- Standard components: ±50μm (3σ)

- BGA components: ±75μm (3σ)

Vision System Optimization

- High-resolution cameras (5-10μm pixel size)

- Advanced lighting systems

- Pattern recognition algorithms

- Real-time placement verification

Feeder Management

- Component verification: Automated part number checking

- Splice detection: Continuous tape monitoring

- Inventory tracking: Real-time component consumption

- Moisture control: Dry storage and baking protocols

Reflow Soldering Mastery

Profile Development Process

Temperature Profiling Zones

- Preheat Zone: 150-180°C, 60-120 seconds

- Thermal Soak: 150-200°C, 60-120 seconds

- Reflow Zone: Peak temperature, 10-30 seconds

- Cooling Zone: <6°C/second cooling rate

Critical Parameters

- Peak temperature: Tpeak = Tmelt + 20-40°C

- Time above liquidus: 45-90 seconds

- Heating rate: 1-3°C/second

- Cooling rate: 2-6°C/second

Advanced Profiling Techniques

- Component-specific profiles: Optimized for critical components

- Board-specific optimization: Thermal mass considerations

- Real-time monitoring: Continuous profile verification

- Statistical process control: Profile consistency tracking

Quality Control Systems

Automated Optical Inspection (AOI)

Pre-reflow AOI

- Solder paste volume and position

- Component presence and orientation

- Polarity verification

- Tombstone detection

Post-reflow AOI

- Solder joint quality assessment

- Component alignment verification

- Defect classification and reporting

- Statistical quality trending

In-Circuit Testing (ICT)

- Continuity testing: Open and short detection

- Component value verification: Passive component testing

- Functional testing: Basic circuit operation

- Boundary scan: Digital circuit verification

X-ray Inspection

- BGA void analysis: Solder joint quality

- Hidden joint inspection: QFN and LGA packages

- Component placement verification: Alignment assessment

- Quantitative analysis: Void percentage calculation

Statistical Process Control (SPC)

Key Metrics Monitoring

- First pass yield: Target >99%

- Defect density: <100 DPMO

- Process capability: Cpk >1.33

- Equipment utilization: >85%

Control Charts Implementation

- X-bar and R charts: Process centering and variation

- P-charts: Defect rate monitoring

- C-charts: Defect count tracking

- CUSUM charts: Process drift detection

Data Collection and Analysis

- Real-time data acquisition

- Automated SPC calculations

- Trend analysis and reporting

- Corrective action tracking

Defect Prevention Strategies

Common SMT Defects and Root Causes

Solder Joint Defects

- Insufficient solder: Low paste volume, poor wetting

- Excess solder: High paste volume, component floating

- Voids: Outgassing, contamination

- Cold joints: Low reflow temperature, oxidation

Component Placement Issues

- Misalignment: Placement accuracy, vision system calibration

- Tombstoning: Unbalanced heating, pad design

- Missing components: Feeder issues, placement verification

- Wrong orientation: Vision system setup, component packaging

Preventive Measures

- Design for manufacturability: Optimized pad designs

- Process standardization: Documented procedures

- Equipment maintenance: Preventive maintenance schedules

- Operator training: Continuous skill development

Advanced Assembly Techniques

Fine Pitch Component Assembly

- 0.4mm BGA: Specialized stencil design and placement

- 01005 components: Ultra-fine pitch capabilities

- Flip chip assembly: Underfill and encapsulation

- Wafer level packaging: CSP assembly techniques

Mixed Technology Assembly

- Through-hole and SMT: Selective soldering integration

- Lead-free and leaded: Process segregation

- High-temperature components: Specialized reflow profiles

- Sensitive components: ESD protection protocols

Industry 4.0 Integration

Smart Manufacturing Features

- IoT connectivity: Equipment monitoring and control

- Predictive maintenance: AI-driven maintenance scheduling

- Digital twin technology: Virtual process optimization

- Blockchain traceability: Component and process tracking

Data Analytics and AI

- Machine learning: Defect prediction and prevention

- Computer vision: Advanced inspection capabilities

- Process optimization: AI-driven parameter adjustment

- Quality prediction: Real-time yield forecasting

Environmental and Compliance Considerations

Lead-Free Assembly

- SAC alloys: Tin-silver-copper compositions

- Higher reflow temperatures: 245-260°C peak

- Flux selection: No-clean and water-soluble options

- Component compatibility: Lead-free terminations

RoHS Compliance

- Material verification: Supplier certification

- Process documentation: Compliance tracking

- Testing protocols: XRF analysis and verification

- Continuous monitoring: Supply chain management

Conclusion

Achieving SMT assembly excellence requires a holistic approach combining advanced equipment, optimized processes, comprehensive quality control, and continuous improvement. The integration of Industry 4.0 technologies and data-driven decision making enables manufacturers to achieve zero-defect production standards while maintaining high throughput and cost efficiency.

At Highleap PCB, our commitment to SMT assembly excellence is demonstrated through our investment in state-of-the-art equipment, rigorous process control, and continuous improvement initiatives.

Contact our assembly engineering team for detailed process optimization and quality improvement consultations.