Surface Mount Technology (SMT) assembly represents the pinnacle of modern electronics manufacturing, enabling the creation of compact, high-performance electronic devices that power our digital world.

Introduction to SMT Assembly

SMT assembly involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), eliminating the need for through-hole mounting in most applications. This technology enables:

- Higher component density

- Improved electrical performance

- Reduced manufacturing costs

- Enhanced reliability

SMT Assembly Process Flow

1. Solder Paste Application

The process begins with precise solder paste application using stencils:

Stencil Design Considerations:

- Aperture size optimization

- Paste release characteristics

- Registration accuracy

- Cleaning requirements

Process Parameters:

- Squeegee pressure: 2-4 kg/cm

- Print speed: 10-25 mm/s

- Separation speed: 0.5-3 mm/s

- Snap-off distance: 0-2 mm

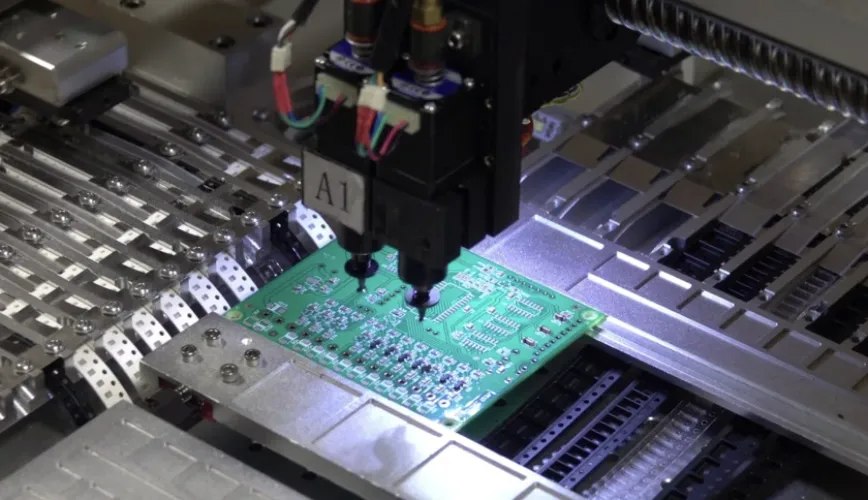

2. Component Placement

High-speed pick-and-place machines position components with exceptional accuracy:

Placement Accuracy:

- Standard components: ±50μm

- Fine pitch components: ±25μm

- Ultra-fine pitch: ±15μm

Component Types:

- Resistors and capacitors (0201, 0402, 0603, 0805)

- Integrated circuits (QFN, BGA, CSP)

- Connectors and mechanical components

3. Reflow Soldering

The reflow process creates permanent solder joints through controlled heating:

Temperature Profile Zones:

- Preheat: 150-180°C (60-120 seconds)

- Thermal Soak: 150-200°C (60-120 seconds)

- Reflow: 230-250°C (30-90 seconds)

- Cooling: <6°C/second cooling rate

Advanced SMT Technologies

Fine Pitch Components

Modern electronics demand increasingly fine pitch components:

0.4mm Pitch QFP:

- Stencil thickness: 0.1-0.12mm

- Aperture ratio: 0.8-0.9

- Placement accuracy: ±25μm

0.3mm Pitch BGA:

- Solder ball diameter: 0.2-0.25mm

- Pad size: 0.2mm

- Via-in-pad technology required

System-in-Package (SiP)

SiP technology enables multiple functions in a single package:

- Heterogeneous integration

- Reduced form factor

- Improved performance

- Lower power consumption

Quality Control in SMT Assembly

Solder Paste Inspection (SPI)

Real-time inspection of solder paste deposits:

- Volume accuracy: ±10%

- Height uniformity: ±25μm

- Shape analysis: Area ratio >0.6

Automated Optical Inspection (AOI)

Post-placement and post-reflow inspection:

- Component presence/absence

- Polarity verification

- Solder joint quality

- Dimensional accuracy

In-Circuit Testing (ICT)

Electrical verification of assembled boards:

- Continuity testing

- Component value verification

- Short circuit detection

- Functional testing

Process Optimization Techniques

Statistical Process Control (SPC)

Continuous monitoring of key parameters:

- Placement accuracy trends

- Solder paste volume consistency

- Temperature profile stability

- Defect rate tracking

Design for Manufacturing (DFM)

Optimizing designs for SMT assembly:

- Component orientation standardization

- Adequate spacing for inspection

- Thermal balancing considerations

- Test point accessibility

Common SMT Defects and Solutions

Solder Joint Defects

| Defect Type | Cause | Solution |

|---|---|---|

| Insufficient Solder | Low paste volume | Optimize stencil design |

| Solder Bridges | Excessive paste | Reduce aperture size |

| Tombstoning | Thermal imbalance | Adjust pad design |

| Head-in-Pillow | Oxidation | Improve storage conditions |

Component Placement Issues

Misalignment:

- Root cause: Machine calibration

- Solution: Regular maintenance and calibration

Missing Components:

- Root cause: Feeder issues

- Solution: Preventive maintenance program

Industry 4.0 in SMT Assembly

Smart Manufacturing

Integration of IoT and AI technologies:

- Real-time process monitoring

- Predictive maintenance

- Automated quality control

- Data-driven optimization

Traceability Systems

Complete product lifecycle tracking:

- Component genealogy

- Process parameter recording

- Quality data correlation

- Rapid issue resolution

Environmental Considerations

Lead-Free Soldering

RoHS compliance requirements:

- SAC305 alloy (Sn96.5/Ag3.0/Cu0.5)

- Higher reflow temperatures

- Improved flux chemistry

- Enhanced process control

Energy Efficiency

Sustainable manufacturing practices:

- Optimized reflow profiles

- Energy recovery systems

- Reduced material waste

- Eco-friendly cleaning processes

Future Trends in SMT Assembly

Emerging Technologies

Embedded Components:

- Components within PCB substrate

- Reduced assembly complexity

- Improved electrical performance

3D Packaging:

- Vertical integration

- Through-silicon vias (TSV)

- Wafer-level packaging

Market Drivers

- 5G communication requirements

- Automotive electrification

- IoT device proliferation

- Miniaturization demands

Conclusion

SMT assembly continues to evolve, driven by the demands of modern electronics. Success requires:

- Advanced equipment capabilities

- Rigorous process control

- Continuous improvement mindset

- Investment in technology

At Highleap PCB, we combine state-of-the-art SMT assembly capabilities with decades of experience to deliver exceptional results for our customers across all industries.

Ready to optimize your SMT assembly process? Contact our engineering team for a comprehensive consultation on your next project.