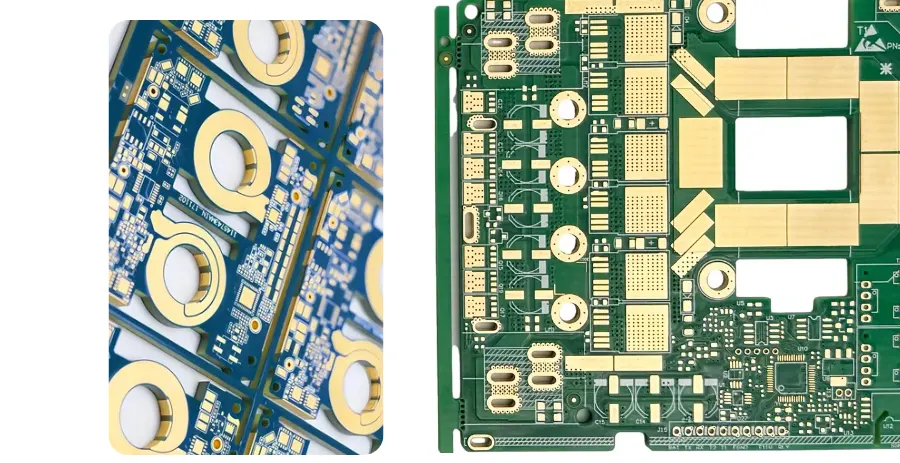

In high-power electronics, traditional PCBs using 1 oz or 2 oz copper often cannot handle the required current loads or thermal dissipation. This is where thick copper PCBs—also known as heavy copper PCBs—come into play.

A thick copper PCB typically features copper layers of 3 oz (105μm) or more. These boards are engineered for reliability under high current, high temperature, or mechanically stressful environments. They are commonly used in:

- Power supply modules

- EV battery protection and charging systems

- Solar inverter circuits

- Industrial motor controllers

- Military or aerospace-grade systems

Highleap PCB Factory has manufactured multi-layer 6 oz and hybrid boards (e.g., 4 oz power layers + 1 oz signal layers) that pass thermal cycling, vibration, and environmental tests for clients in the EV and renewable energy sectors. These use cases emphasize the importance of both electrical performance and mechanical reliability under real-world conditions.

1. What Is a Thick Copper PCB and Why Use It?

A thick copper PCB is any printed circuit board that uses copper layers thicker than 3 oz/ft². While typical PCBs use 1 oz copper, thick copper designs often range from 3 oz to 10 oz depending on current, thermal, and mechanical demands.

Use Cases

Thick copper is essential in high-current applications (40A–100A), such as:

- DC/DC converters

- Battery management systems

- Industrial drivers and servo controllers

- Power distribution backplanes

- High-voltage energy systems

Why Engineers Choose Thick Copper

- Current handling: Larger cross-section lowers resistive losses

- Thermal reliability: Heavy copper acts as a heat spreader

- Mechanical strength: Reduces risk of track damage under stress

- Short-circuit resilience: Handles transient surge energy

- Reduced voltage drop: Better voltage stability in high-load zones

2. Design Guidelines for Thick Copper PCBs

Designing a thick copper PCB isn’t just about increasing copper weight. It impacts layout rules, impedance, stackup construction, and DFM.

a. Trace Width Calculation

Use IPC-2152 rather than older IPC-2221 charts to size traces. For example, 10A on 4 oz copper may require 100 mil+ trace width depending on temperature rise and airflow. Online calculators are not enough—confirm with your manufacturer.

b. Heat Management

Thick copper helps conduct heat, but proper layer spreading**, **thermal vias, and symmetrical stackups are still essential to avoid hot spots and delamination. Avoid placing all high-power traces on a single layer.

c. Minimum Spacing and Etchability

Heavy copper requires wider trace/space due to overetching. For example:

- 1 oz copper: 4/4 mil

- 4 oz copper: 10/10 mil typical

- 6 oz copper: ≥12 mil preferred

Always consult your fabricator’s capability chart.

d. Balanced Stackup Design

To prevent bow/twist, maintain copper symmetry across layers. If the outer layer is 6 oz, inner layers must be adjusted accordingly. Unbalanced designs often warp during reflow or thermal cycles.

3. Key Considerations When Sourcing Thick Copper PCBs

a. DFM and Stackup Validation

At Highleap PCB Factory, we help customers validate stackups before production. We consider:

- Resin flow under high copper weight

- Layer bonding temperature and Tg rating

- Hole wall plating for thick-layered designs

Early engagement avoids surprises during manufacturing.

b. Quality and Reliability Standards

Our thick copper boards meet IPC-6012 Class 2 or Class 3 based on your reliability targets. Each job includes:

- Verified copper thickness tolerances (±10%)

- Optional microsection and thermal cycling reports

- 100% E-test and impedance verification (if required)

Thick copper is not only about build—it’s about repeatable performance in production.

c. Lead Time and Capacity

Typical lead times:

- Prototypes: 7–10 working days

- Low-volume: 10–14 working days

- Mid-volume: up to 18 working days

Rush services are available. Stackups are reviewed before confirming production windows to ensure schedule alignment.

d. Cost Drivers and Quoting Advice

Factors affecting cost:

- Higher copper material and press cycles

- Drill wear and slow feed rates

- AOI and etch tolerance adjustments

To optimize cost:

- Use only the copper weight you need

- Combine signal and power with hybrid stackups

- Ask for standard material options if possible

We offer transparent quotations with stackup details, and engineering suggestions to reduce cost without sacrificing reliability.

e. Shipping and Handling

Thick copper PCBs are heavier and less flexible. We use:

- Vacuum-sealed and ESD-safe inner packs

- Rigid foam + outer carton protection

- Global courier options with customs-ready paperwork

For multi-board shipments, we offer combined PCB + PCBA packaging to reduce transit cost and risk.

4. Thick Copper PCB Assembly: Real-World Adjustments for Reliable Production

a. Reflow and Thermal Mass

Heavy copper acts as a heat sink during reflow. This requires:

- Slower ramp-up and extended soak times

- Preheating for selective soldering

- Step stencils or solder paste volume adjustment

At Highleap PCB Factory, all thick copper reflow profiles are tuned in-house based on stackup simulation.

b. Pad Design and CAM Optimization

We adapt pad design for thermal relief and solder wetting. Techniques include:

- Thermal spokes on large copper pours

- Solder mask-defined pads for heat control

- Via-in-pad filling to reduce wicking on inner copper planes

Our CAM team reviews your data and recommends layout adjustments if needed, especially for boards with heavy copper ground fills or high-density components.

Conclusion: Manufacturability Starts With Engineering Awareness

Thick copper PCBs are essential for modern power electronics, but they are only successful when design, manufacturing, and assembly align.

At Highleap PCB Factory, we don’t just fabricate—we advise, validate, and deliver. Our goal is to ensure your thick copper board is electrically sound, mechanically reliable, and production-ready from the first batch to the last.

Whether you're designing a rugged industrial motor controller, a high-current battery module, or a compact solar power converter, we’re ready to support you from stackup design through on-time shipment.