Through-hole assembly remains a foundational process in electronics manufacturing. Despite the widespread adoption of surface mount technology (SMT), through-hole technology (THT) retains a critical role in many applications where mechanical strength, thermal resilience, or legacy design support is necessary. This comprehensive guide covers everything from the basics of THT to its advantages, the full assembly workflow, design considerations, and industry applications.

What is Through-Hole Assembly?

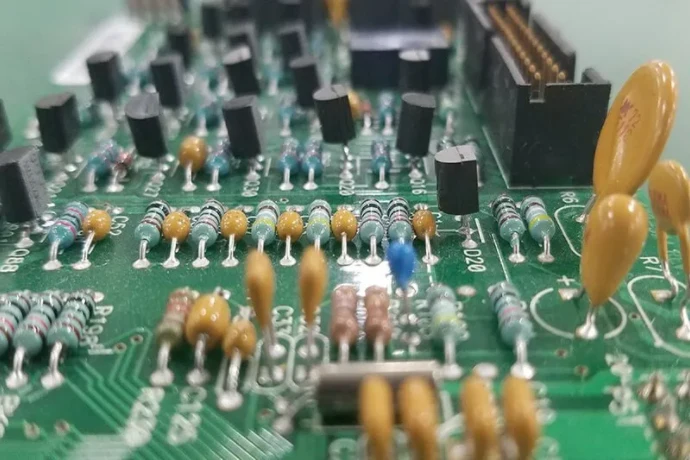

Through-hole assembly is the process of inserting electronic component leads into drilled holes on a printed circuit board (PCB), then soldering the leads on the opposite side for mechanical and electrical bonding. These holes are plated to ensure connectivity across layers of the PCB. While SMT places components on the board surface, THT enables robust vertical anchoring.

Components such as resistors, diodes, capacitors, connectors, and ICs with pins are commonly mounted using through-hole techniques. THT is particularly prevalent in applications requiring structural durability, such as power electronics, military systems, and industrial machinery.

In prototyping environments, through-hole components are favored for their ease of handling, reworkability, and suitability for breadboards or perfboards. THT’s compatibility with hand soldering also makes it a preferred choice in research and educational settings.

Advantages of Through-Hole Assembly Over SMT

Although SMT is the norm for compact and high-speed circuits, through-hole assembly offers key benefits in specialized use cases:

Mechanical Durability: THT components are anchored through the PCB, making them ideal for parts exposed to mechanical vibration or handling, such as connectors, transformers, or high-rel switches.

High Voltage and Power Tolerance: The larger leads of through-hole components dissipate heat more effectively, which makes them suitable for power converters, amplifiers, and electric vehicle control units.

Ease of Prototyping: Engineers favor through-hole components for quick iterations and testing. They can easily be inserted, removed, or swapped without expensive SMT rework stations.

Improved Reliability for Harsh Environments: Aerospace, automotive, and defense industries continue to favor THT for mission-critical electronics due to its enhanced solder integrity and resistance to shock and temperature extremes.

Legacy Component Compatibility: Many specialized ICs and analog devices are still manufactured in through-hole packages. THT provides continued support for legacy designs without the need for redesign.

The Through-Hole Assembly Process

A complete through-hole assembly workflow includes several distinct stages designed to ensure precise and durable component integration:

1. PCB Drilling and Plating: The PCB is manufactured with pre-drilled holes based on the BOM and mechanical drawings. These holes are plated through (PTH) with copper to connect internal layers electrically.

2. Component Preparation: Components are often lead-trimmed or bent into a required form factor to match hole spacing. Automated lead formers can handle axial or radial lead shaping for high volumes.

3. Component Insertion: Leads are inserted manually for prototypes or using auto-insertion machines in production. Axial, radial, and odd-form component inserters improve placement consistency and speed.

4. Soldering: Components are soldered via:

- Wave Soldering: Boards pass over a wave of molten solder, bonding all inserted leads simultaneously.

- Selective Soldering: Targeted soldering for specific components when the board also contains SMT parts.

- Manual Soldering: Used for low-volume builds, sensitive components, or rework.

5. Cleaning: Post-solder cleaning removes flux residue to prevent long-term corrosion or signal interference. Both aqueous and no-clean fluxes are used depending on the process.

6. Inspection and Testing:

- AOI: Detects lead misalignment, missing parts, or poor joints.

- X-Ray: Useful for verifying internal joints or multi-layer penetration.

- ICT and Functional Testing: Verifies electrical performance before shipping.

Challenges in Through-Hole PCB Assembly

Despite its benefits, THT assembly involves certain limitations:

Longer Assembly Times: Insertion and soldering are slower than automated SMT lines, affecting throughput in high-volume applications.

Design Constraints: Board real estate must be allocated for hole routing, which can limit multilayer or high-density design flexibility.

Lead Damage: Improper trimming or insertion force may damage fragile leads or PCB vias, especially on manually assembled boards.

Soldering Variability: Manual and wave soldering can yield inconsistent joints if process parameters are not tightly controlled.

Manufacturers can overcome these challenges by integrating smart tooling, standardized lead trimming, design-for-assembly reviews, and combining THT with SMT workflows for balance and efficiency.

Best Practices for Design and Manufacturing Optimization

To maximize yield, reliability, and manufacturability in through-hole PCB design, consider the following:

- Optimal Hole Sizes: Maintain 0.2–0.25 mm clearance between the lead and the hole for proper solder flow and anchoring.

- Component Spacing: Allow clearance for soldering and inspection, especially near SMT regions.

- Wave Solder-Friendly Orientation: Align axial parts perpendicular to solder flow and prevent shadowing by large components.

- Use Fiducials and Silkscreen Markings: Aid alignment for auto-insertion and aid technicians during manual assembly.

- Pre-Assembly Lead Forming: Minimize in-board stress by pre-forming leads to fit precisely without forceful bending.

- Thermal Relief Pads: On multilayer boards, use thermal reliefs to ease soldering of pins connected to ground or power planes.

- Test Point Accessibility: Design for easy probing of nets and functional blocks, especially if THT is part of a diagnostic workflow.

These tips help reduce defects, enable smoother handoff between design and assembly, and enhance product reliability.

Industry Use Cases for Through-Hole Assembly

Through-hole technology continues to serve critical roles in various industries:

- Automotive Electronics: In ECUs, powertrain modules, and sensor interfaces, through-hole parts withstand thermal cycles and road vibration.

- Aerospace Systems: THT components are specified in satellites, radar systems, and avionics due to proven mechanical integrity.

- Industrial Automation: PLCs, motor drivers, and field controllers benefit from the robustness of THT assembly in factory conditions.

- Medical Equipment: From imaging systems to life-support hardware, through-hole mounting ensures safety-critical components remain reliably attached.

- Power Electronics: AC-DC converters, battery chargers, and power inverters often use THT for high-current paths and secure pin connection.

- Education and Development Boards: THT is ideal for training kits, university courses, and maker projects due to its simplicity and reusability.

As more designs blend digital logic with analog control or power delivery, hybrid SMT + THT solutions offer the best of both worlds.

Let Highleap Build Your Through-Hole Assembly Project

Highleap PCB Factory offers complete turnkey solutions for through-hole PCB assembly. Whether you need a rugged industrial controller, a power supply unit, or a mixed-technology board with both SMT and THT, we can help.

With experienced engineers, advanced wave soldering lines, and strict IPC quality controls, we deliver high-reliability assemblies for every industry. Send us your Gerber files and BOM for a quick quote and professional feedback.