In an era where data rates exceed 100 Gbps and RF systems push beyond 40 GHz, conventional circuit board materials reach their physical limits. Losses in the dielectric and conductor begin to erode signal margins, shrink jitter budgets, and compromise system reliability. This is where the ultra-low-loss PCB comes in-a circuit board engineered with elite materials and precision fabrication to minimize insertion loss, preserve signal fidelity, and enable the next generation of high-speed electronics.

This comprehensive guide will explore what differentiates an ultra-low-loss PCB from standard designs, how to select the right materials, and the critical design and manufacturing practices required to achieve peak performance in systems like data centers, 5G infrastructure, and satellite communications.

Table of Contents

- What Defines an Ultra-Low-Loss PCB?

- Key Factors Affecting Signal Integrity

- A Tiered Guide to Selecting Ultra-Low-Loss Laminates

- Design Strategies to Maximize Ultra-Low-Loss PCB Performance

- Why Manufacturing Precision is Non-Negotiable

- Key Applications Driving the Need for Ultra-Low-Loss PCBs

What Defines an Ultra-Low-Loss PCB? {#what-defines-an-ultra-low-loss-pcb}

At its core, an ultra-low-loss PCB is defined by one primary characteristic: dramatically lower signal attenuation, especially at high frequencies. Compared to standard boards, the benefits are clear:

- Significantly Lower Insertion Loss: Enables longer trace runs on a backplane or higher data rates without the need for costly re-drivers or repeaters.

- Superior Phase Stability and Lower Dispersion: Critical for coherent communication systems, phased-array antennas, and high-frequency RF applications.

- Reduced Signal Heating: Minimizes both conductor and dielectric heating, which improves power handling and long-term reliability.

- Higher Signal-to-Noise Ratio (SNR): Preserves the integrity of the signal, enabling the use of advanced, high-order modulation schemes.

While standard FR-4 may suffice for basic digital logic, when your loss budget is tight-whether in a high-speed serial link or a millimeter-wave radar module-an ultra-low-loss design is no longer an option, but a necessity.

Key Factors Affecting Signal Integrity {#key-factors-affecting-signal-integrity}

To engineer an ultra-low-loss PCB, designers must combat three fundamental sources of signal degradation:

1. Dielectric Loss (Measured by Dissipation Factor, Df): This is the most critical factor. Dielectric loss quantifies how much of a signal's electromagnetic energy the substrate material absorbs and converts into heat. It is like an "electrical friction" that weakens the signal as it travels. Ultra-low-loss materials are defined by their extremely low Df values, often below 0.002 at target frequencies.

2. Conductor Loss (Affected by Copper Roughness): At high frequencies, current travels only on the outer surface of a trace (the skin effect). Rough copper foil increases the effective path length and resistance of the trace, increasing the conductor loss. Ultra-low-loss designs mandate the use of Very-Low-Profile (VLP) or smooth reverse-treated copper foils to minimize this effect.

3. Dispersion (Affected by Dielectric Constant, Dk, Stability): While a low Dk is beneficial for signal speed, its stability across frequency is what truly sets high-performance materials apart. Materials whose Dk changes with frequency will cause dispersion, where different frequency components of a signal arrive at different times. This "smears" the signal, distorts its waveform, and closes the data eye.

A Tiered Guide to Selecting Ultra-Low-Loss Laminates {#a-tiered-guide-to-selecting-ultra-low-loss-laminates}

Choosing the right laminate is the most important decision in a low-loss design. Here are the key tiers of materials:

- Tier 1: High-Performance Epoxies and Hybrids (Df ~0.004 - 0.008): These materials represent a significant step up from standard FR-4 and are suitable for many high-speed digital applications. They offer a good balance of performance, cost, and manufacturability.

- Tier 2: Hydrocarbon and Ceramic-Filled Blends (Df ~0.002 - 0.004): This category is the workhorse for today's most demanding digital and high-frequency systems. They provide excellent performance for 56/112 Gbps data channels and many RF applications.

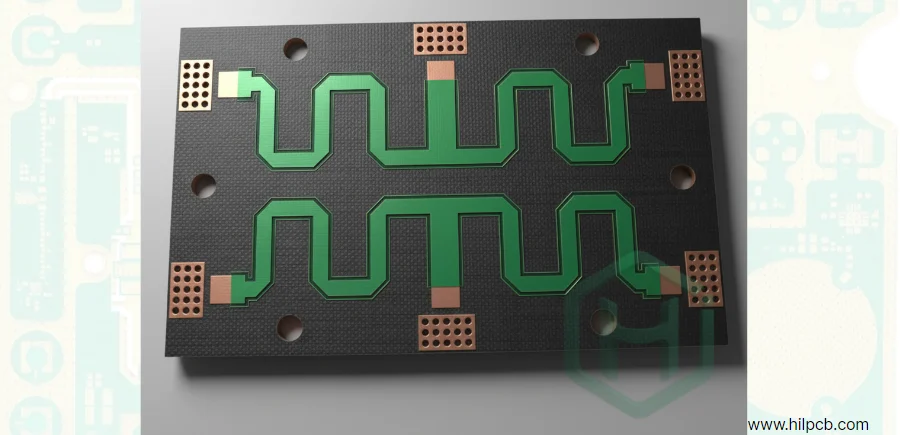

- Tier 3: PTFE-Based Laminates (Teflon™) (Df < 0.002): This is the gold standard. PTFE and its composites offer the lowest dielectric loss possible, making them the only choice for mission-critical millimeter-wave radar, satellite communications, and the most advanced high-speed test equipment.

Pro Tip: Always specify the exact material datasheet and the frequency at which Dk/Df values must be met. This prevents "performance surprises" when the manufactured board is tested.

Design Strategies to Maximize Ultra-Low-Loss PCB Performance {#design-strategies-to-maximize-performance}

Even the highest-performance material can be undermined by suboptimal design. Achieving minimal loss and maximal signal fidelity requires a combination of careful planning, simulation, and layout discipline. Here are the most effective strategies:

Leverage Advanced Field Solvers for Accurate Impedance Modeling:

Generic calculators often fail to capture the nuanced interactions of ultra-low-loss materials and complex copper profiles. Modern field solvers simulate electromagnetic behavior, taking into account the precise dielectric constant, copper roughness, and trace geometry. This ensures that high-frequency traces maintain their intended characteristic impedance across the board, reducing reflections and preserving signal integrity.Minimize Trace Lengths and Avoid Unnecessary Bends:

Every millimeter of copper introduces insertion loss and phase delay. Keeping traces as short, direct, and smooth as possible not only reduces dielectric and conductor losses but also lowers the risk of crosstalk and signal distortion. Gentle curves are preferable to sharp 90° bends, which can create impedance discontinuities at high frequencies.Eliminate Signal Stubs and Optimize Via Design:

Unused via stubs act like tiny antennas at high frequencies, creating resonant nulls that degrade your signal. Techniques such as back-drilling, blind vias, or buried vias remove these stubs, preventing reflection-induced distortion. Proper via design-including pad size, anti-pad spacing, and plating quality-also plays a critical role in maintaining consistent impedance and minimizing parasitic inductance.Ensure a Continuous and Low-Inductance Return Path:

High-speed signals demand an uninterrupted ground plane adjacent to each trace. A solid return path reduces loop area, maintains impedance, and minimizes electromagnetic interference (EMI). Layer stack-up planning, careful separation of signal layers from power planes, and strategic stitching of vias are all essential practices for maintaining a stable return current path.Control Crosstalk and Layer Interactions:

High-density layouts increase the risk of crosstalk. Maintain adequate spacing between high-speed signals, consider differential pair routing for noise immunity, and use shielding layers when necessary. Simulation tools can predict coupling between layers, enabling design adjustments before fabrication.Iterate and Validate Through Simulation:

Even with the best design practices, ultra-low-loss PCBs require verification. Time-domain and frequency-domain simulations-using S-parameters and eye-diagram analysis-can validate whether the layout meets the target insertion loss, return loss, and signal rise/fall requirements before production.

By integrating these strategies, engineers can fully exploit the advantages of ultra-low-loss materials, achieving minimal insertion loss, stable impedance, and maximal signal fidelity, even in the most demanding high-speed or RF applications.

Why Manufacturing Precision is Non-Negotiable {#why-manufacturing-precision-is-non-negotiable}

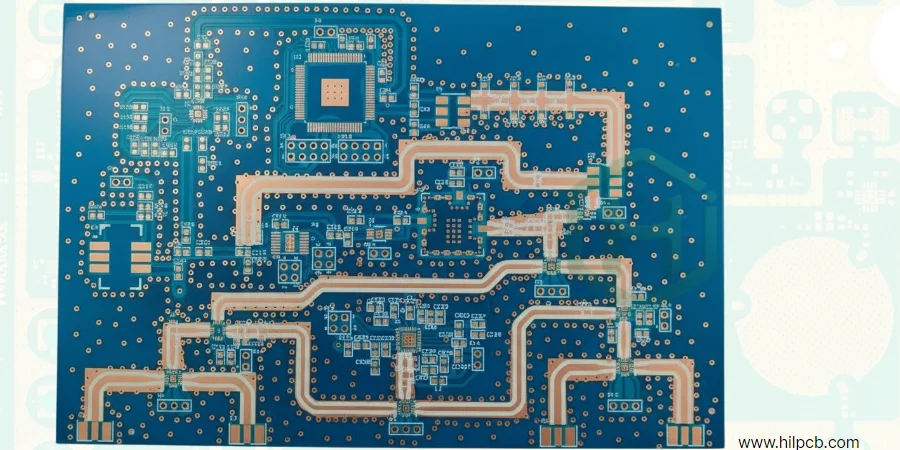

Ultra-low-loss PCBs demand a higher level of fabrication expertise. Key areas of focus include:

- Specialized Lamination and Bonding Processes: Materials like PTFE require unique temperature profiles and bonding films that differ from standard FR-4 processing.

- High-Precision Drilling and Plating: The soft nature of many low-loss substrates requires specialized drilling techniques to create clean, reliable via barrels essential for signal integrity.

- Rigorous Quality Verification: Performance must be proven, not assumed. We use Time-Domain Reflectometry (TDR) to verify impedance on every panel and S-parameter measurements with a network analyzer to confirm the board meets its specified insertion loss budget.

Key Applications Driving the Need for Ultra-Low-Loss PCBs {#key-applications-driving-the-need-for-ultra-low-loss-pcbs}

The demand for this technology is driven by industries where every decibel of loss and every picosecond of delay matters:

- Data Center Backplanes and Line Cards (100/400/800 Gbps)

- 5G and 6G mmWave Infrastructure (Phased-Array Antennas)

- Automotive Radar and ADAS (77 GHz and Beyond)

- Satellite and Aerospace Communication Payloads

- High-Speed Test and Measurement Equipment

Conclusion

Designing ultra-low-loss PCBs goes beyond choosing the right material-it requires a holistic approach that combines advanced laminates, careful layout, and precision manufacturing. By addressing dielectric and conductor losses, controlling signal stubs, and maintaining clean return paths, engineers can preserve signal integrity even at the highest data rates.

For applications like high-speed data centers, 5G/6G infrastructure, radar systems, and satellite communications, an ultra-low-loss PCB isn’t just a technical improvement-it’s a critical enabler of performance, reliability, and future-proof designs. Investing in meticulous design and fabrication today ensures that your systems can handle tomorrow’s speed and complexity with confidence.